Battery Pack Remaining Charge (SOC) With the wide application of...

Laser cutting process

Laser cutting is a high precision, high efficiency processing technology, it plays a crucial role in the wafer manufacturing. This process uses a laser beam of high power density to illuminate the material, so that the material quickly melts, vaporizes or reaches the ignition point, so as to achieve cutting. The characteristics of laser cutting include fast cutting speed, high cutting accuracy, small heat affected zone, and smooth cutting edge.

Process flow

The flow of laser cutting process usually includes the following steps:

Design and programming: The desired cutting pattern is first created in Computer Aided Design (CAD) software, and then the CAD file is converted into a format compatible with the laser cutting machine.

Material preparation: Clean and fix the material to be cut on the laser cutting bed.

Cutting operation: The laser cutting machine cuts the material through the focused laser beam according to the programmed path.

Cutting quality inspection: After the cutting is completed, the quality inspection of the cutting surface is carried out to ensure the cutting accuracy and surface quality.

Technical Features

Laser cutting technology has the following characteristics in the manufacture of grade sheet:

High accuracy: Laser cutting can achieve micron-level cutting accuracy, which is essential for extremely size-critical applications in wafer fabrication.

Flexibility: The laser cutting machine can quickly adjust the cutting pattern to adapt to the production of different shapes and sizes of stage pieces, with high flexibility.

Automation: The laser cutting process can be fully automated to improve production efficiency and reduce labor costs.

Non-contact processing: Laser cutting is a non-contact processing method that reduces the mechanical stress of the material and helps to improve the quality of the product.

Field of application

The application of laser cutting technology in wafer manufacturing is very broad, including but not limited to:

Electronic industry: used in the manufacture of electronic components shell, connector, etc.

Automotive industry: used in the production of auto parts, such as body panels, engine parts, etc.

Aviation industry: used to manufacture lightweight, high-strength aircraft components.

Trend of development

With the progress of science and technology, the application of laser cutting technology in wafer manufacturing is also developing. Future trends may include:

Intelligent: through the introduction of artificial intelligence technology, the intelligent control and optimization of laser cutting process are realized.

Precision: improve the precision of laser cutting, to meet the requirements of higher standards of products.

Environmental protection: develop more environmentally friendly cutting processes to reduce energy consumption and waste emissions.

Laser cutting technology plays a more and more important role in wafer manufacturing with its unique advantages. With the continuous progress of technology, laser cutting technology will usher in a broader development prospect in the field of chip manufacturing.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

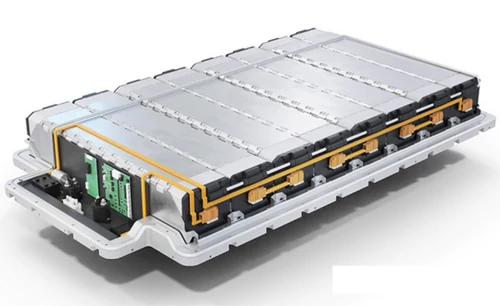

Function analysis of battery pack housing

Function analysis of battery pack housing Battery pack housing is...

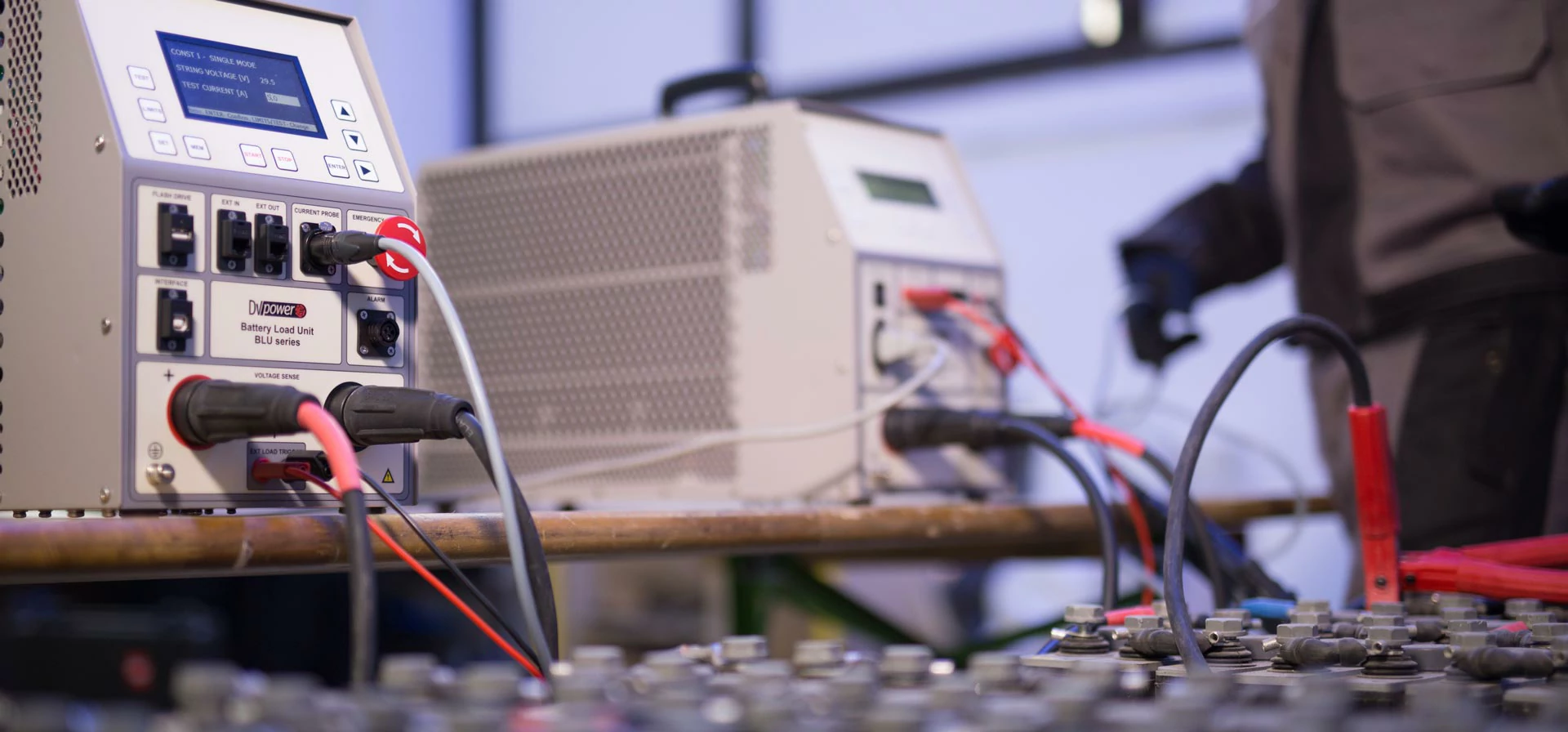

Capacity testing of single cell batteries

Capacity testing of single cell batteries As the most basic...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.