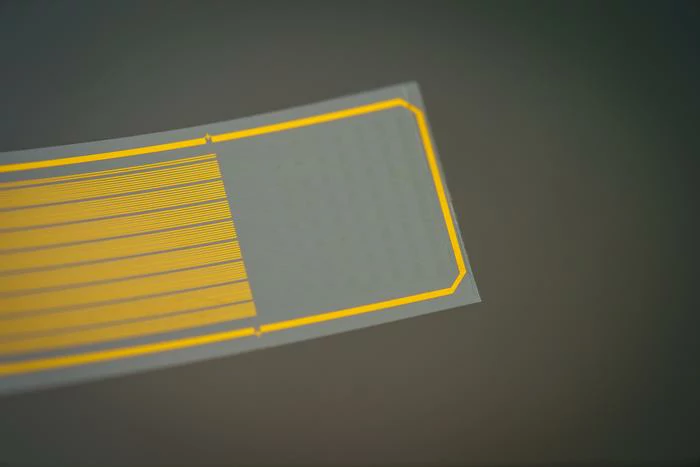

Application of transparent electrode in display Main component Transparent electrode...

Introduction to the wires and connectors in the DC charging pile indicator light

Main component

The wires and connectors in the indicator light are important components to ensure its proper operation and safety. They establish a strong electrical connection between the power supply and the indicator light, which plays a decisive role in the performance and reliability of the luminaire.

Wires are usually made of conductive metal, such as copper, with insulation wrapped around them to prevent current leakage and short circuits. Different indicator application scenarios require different specifications and types of wires. For example, in high temperature or humid environments, high temperature or waterproof wires are usually selected to ensure reliability and safety. In addition, the thickness of the wire also affects the carrying capacity of the current, the designer needs to choose the appropriate wire specifications according to the power of the indicator light to avoid overload and possible failure.

The connector is used in the indicator to connect the wire with the internal circuit of the lamp or other equipment, and plays the role of signal transmission and power connection. Common connector types include plugs, receptacles, and terminal blocks. High-quality connectors have good electrical conductivity and corrosion resistance, and can withstand repeated insertion and removal without loosening or poor contact. Some connectors are also water-resistant to maintain a stable connection in harsh environments.

In short, the selection of wires and connectors not only affects the electrical performance of the indicator, but also relates to its safety. When choosing these components, designers need to take into account the working environment, power requirements and safety standards to ensure that the indicator can work reliably under a variety of conditions.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Components of the control module

Components of the control module Dc charging pile control module...

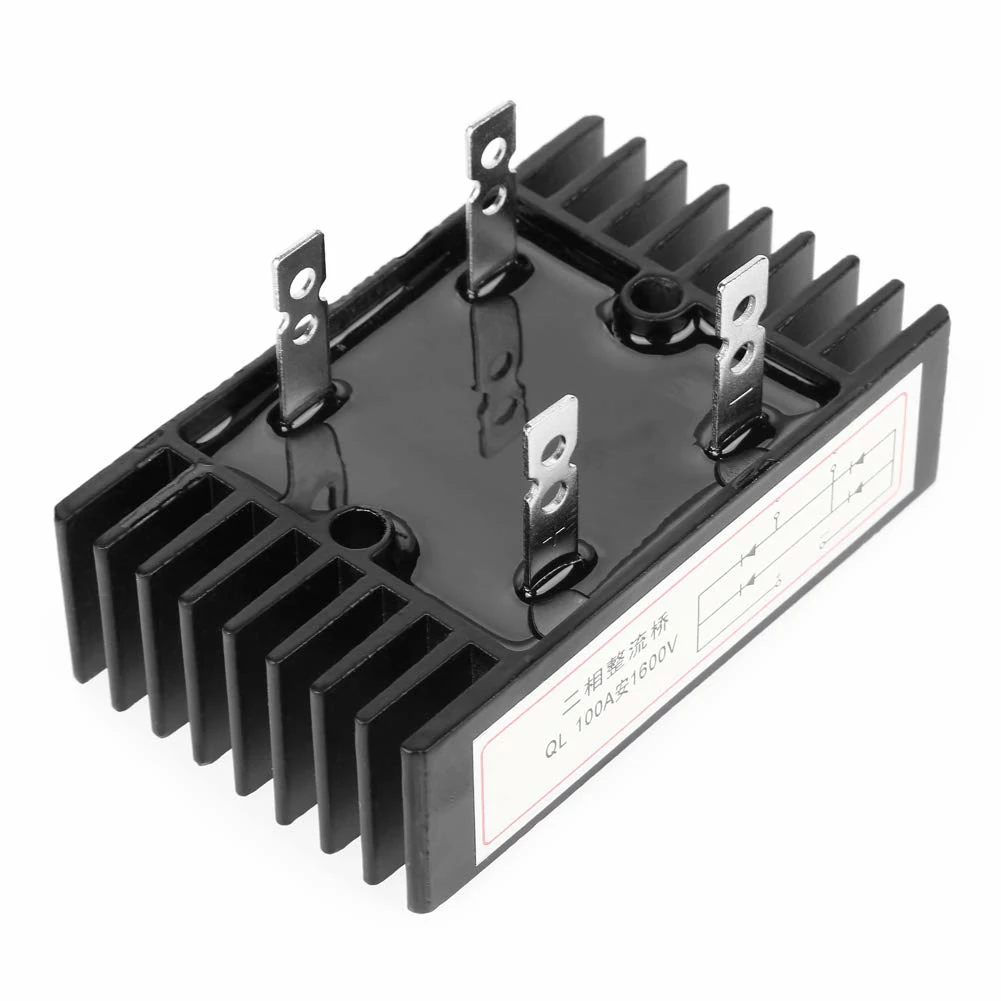

The components of the rectifier of the charging module

A highly integrated backup power solution for solar home energy...

How is the emergency stop button of DC charging pile designed?

How is the emergency stop button of DC charging pile...

What is the function of the insulator of the communication contact?

What is the function of the insulator of the communication...

What is the effect of modified plastics on the case of DC charging pile?

What is the effect of modified plastics on the case...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.