How to test the voltage drop of a single battery...

Introduction to the testing process of lithium iron phosphate monomer battery

Lithium iron phosphate (LiFePO4) battery has gradually become the preferred power source for electric vehicles, energy storage systems and other high-performance applications due to its good safety, long cycle life and stable performance. In order to ensure the reliability and safety of the lithium iron phosphate battery in use, the finished battery must go through a series of strict tests. The types and flow of these tests are described in the following.

Appearance inspection

Before the battery leaves the factory, it is first inspected for appearance. This phase is mainly to check the physical state of the battery, including:

Housing integrity

Ensure that the battery housing is free of cracks, dents, or other physical damage.

Clear identification

Check whether the battery identification, model, production date and other information is complete and easy to identify.

Connection terminal

Make sure that the connection terminal is free of oxidation, dirt and other substances that affect the connection.

electrical performance test

The electrical performance test is the key to evaluate the actual working ability of the battery, which mainly includes the following aspects:

Charge and discharge test

The battery is subjected to multiple complete charge and discharge cycles to measure whether the actual capacity reaches the nominal capacity. The test is able to evaluate the energy output of the battery at different discharge multiplies.

Calculate the charging efficiency (the ratio of charging input power to discharging output power) to ensure that the energy loss of the battery is as small as possible during charging and discharging.

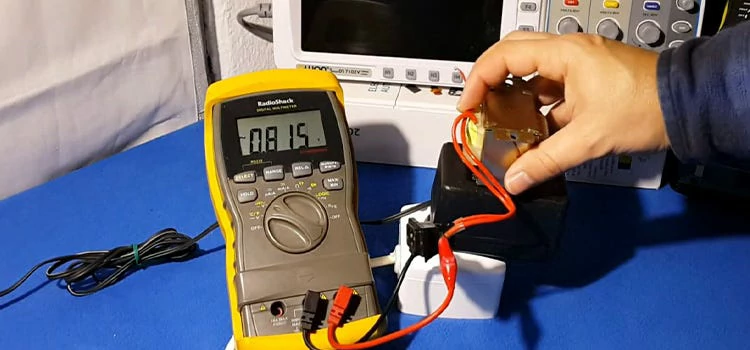

Voltage test

Test the static voltage of the battery when it is not connected to the load to ensure that it is within the normal range (for example, the nominal voltage of the lithium iron phosphate battery cell is generally 3.2V).

The voltage drop of the battery is monitored during charging and discharging to observe whether there is an excessive voltage drop, which may indicate an internal fault.

By testing the AC internal resistance of the battery, the power loss of the battery during charging and discharging can be evaluated. Excessive internal resistance will affect the performance and life cycle of the battery.

Security testing

Safety testing is necessary to ensure battery stability under a variety of extreme conditions, including:

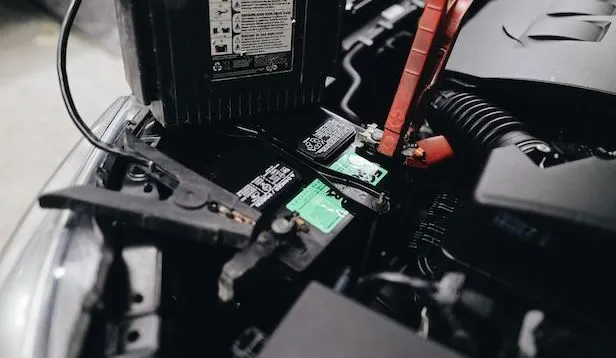

The battery was short-circuited to check its performance under short-circuit conditions. A qualified battery should have self-protection mechanisms to prevent overheating or fire in the event of a short circuit.

The overcharge test is carried out under the specified conditions to observe the reaction of the battery under overcharge protection to ensure its good safety.

The battery was tested in a high temperature environment to observe whether the battery would have adverse reactions such as leakage, expansion, fire or explosion.

The collision and vibration of the battery during transportation and use are simulated to ensure that it can still work stably in harsh environments.

environmental adaptability test

In order to ensure the stability of the battery under different environmental conditions, it is usually necessary to conduct environmental adaptability tests, including:

Battery performance was tested under different temperature conditions, such as -20°C to 60°C, to assess its operational stability in extreme climatic conditions.

Tests were performed under different humidity conditions, such as high and low humidity environments, to ensure that the electrical performance of the battery remained good in humid environments.

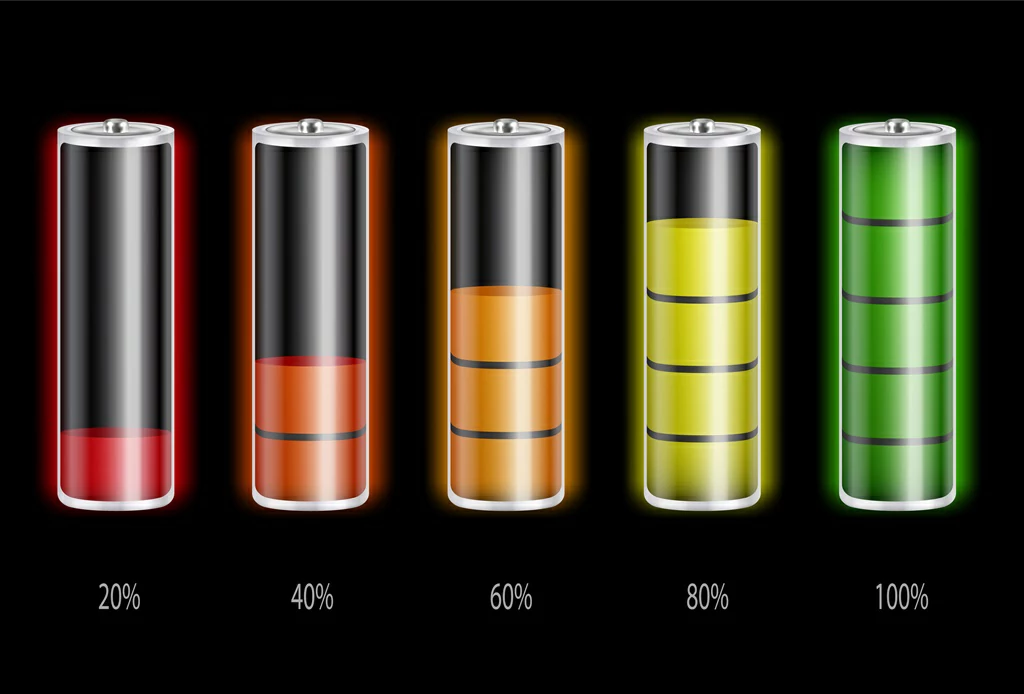

The cycle life test is mainly to evaluate the performance change of the battery under multiple charge and discharge cycles. Generally, the standard charge and discharge rate will be selected and the capacity decay of the battery after 1000 or even 2000 cycles will be observed to determine the battery life cycle.

Conclusion

The lithium iron phosphate monomer battery needs to pass a series of rigorous tests to ensure its performance, safety and adaptability before the finished product leaves the factory. These tests not only help to improve the quality and reliability of the battery, but also guarantee the safety of the end user. In the context of increasing global demand for high performance batteries, testing processes to ensure product quality will be particularly important. As technology advances, these test methods will continue to innovate to meet higher market requirements.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Charging and discharging efficiency test of single battery

Charging and discharging efficiency test of single battery The charging...

Battery Pack Remaining Charge (SOC)

Battery Pack Remaining Charge (SOC) With the wide application of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.