EPS shell material – flame retardant material EPS battery cell...

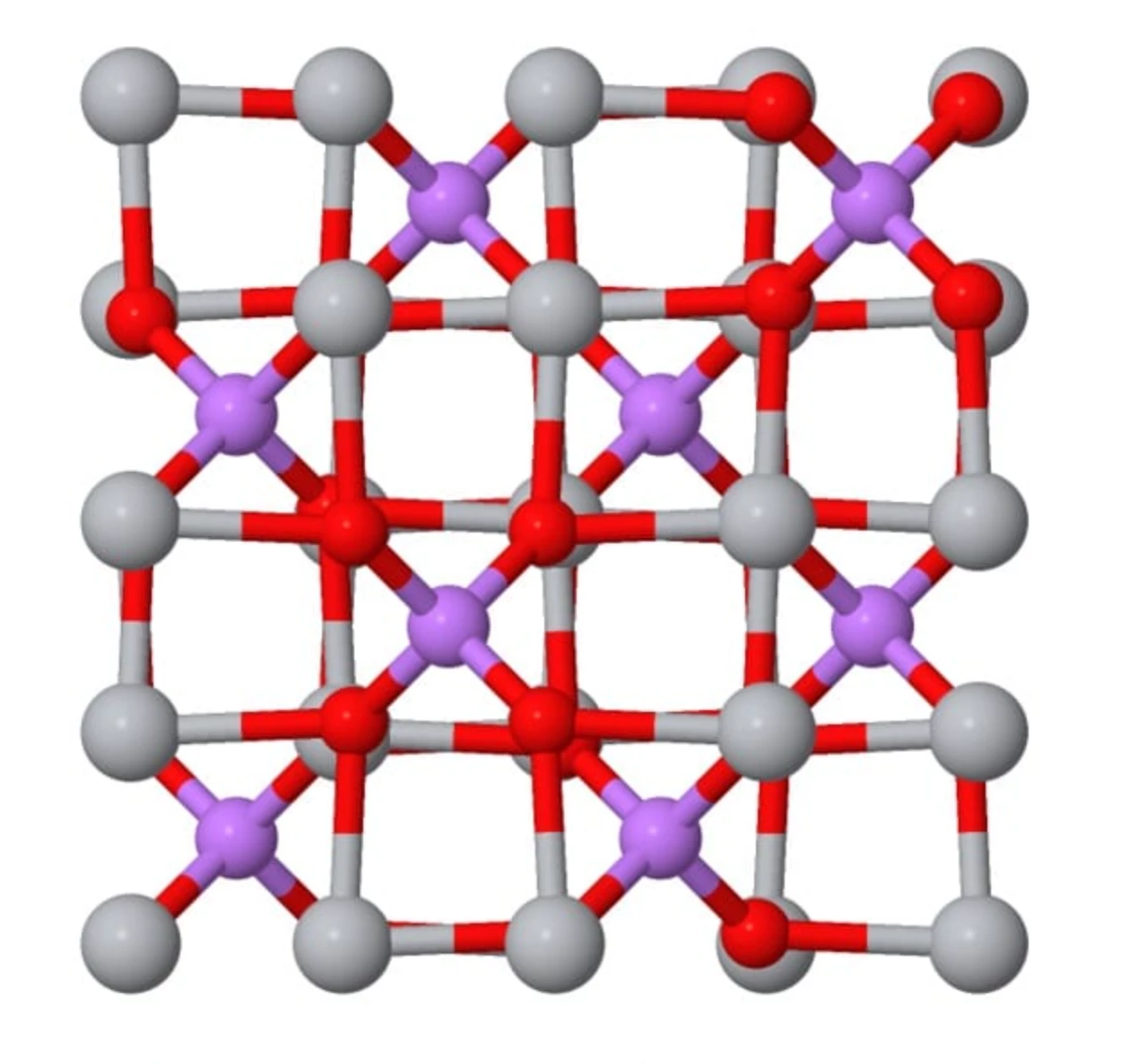

battery shell material of EPS battery unit

The battery housing is an important part of the EPS battery cell, which not only provides structural integrity, but also plays an important role in safety and performance. The following is an introduction to EPS battery cell shell materials according to different material characteristics.

main content

Metallic materials, such as steel, stainless steel and nickel-plated steel, are used in battery casings due to their high strength and durability. The metal housing can effectively dissipate the heat generated during battery operation, contributing to overall safety and performance. In addition, the metal housing has an electromagnetic shielding function, which can prevent interference with other electronic devices. However, metal housings are heavier than plastic or PVC housings, which may not be suitable for some portable applications. Aluminum housings are often used in high-performance applications due to their high strength-to-weight ratio, high thermal conductivity, and beautiful exterior design.

Plastic housings, such as ABS, are widely used due to their lightweight design and design flexibility. The plastic case is lightweight, which is advantageous for weight-conscious portable devices. The plastic housing can be easily molded into complex shapes, enabling creative battery designs. Plastic enclosures are generally more resistant to corrosion than metal enclosures. However, some types of plastic may not be able to withstand high temperatures, potentially causing deformation or reduced battery performance.

Composite plastics

Composite materials, such as carbon fiber reinforced plastics, are used in battery casings due to their lightweight and high strength properties. The composite battery housing can improve thermal insulation, reduce noise, reduce vibration, and reduce acoustic roughness. If the battery case is made of 100% composite material instead of aluminum, the body weight can be reduced by up to 40%. The noise, vibration and acoustic roughness (NVH) of composites are smaller because of their inherent damping properties.

In order to ensure the overall safety of the battery cell, flame retardant materials are crucial in the application of the battery housing. Fire-resistant materials for svt batteries include water-based one-component coatings and two-component polyurethane coatings, as well as fire-resistant fabrics and foams made of cooling or insulating materials. The low weight per unit area of these materials helps ensure a lightweight design for the overall structural weight. In addition, a kind of heat insulation and flame retardant coating material for lithium-ion battery pack shell, including halogen load epoxy resin and amine curing film forming system, flame retardant, foaming expansion agent, carbonizing agent, carbon-based reinforcement filler and hollow microbeads, can expand rapidly at high temperature of fire more than 20 times to block the spread of fire, providing fire escape time of 30 minutes.

The battery case also needs to be waterproof to protect the battery's internal components from moisture. Plastic materials such as PVC and certain high-performance plastics have good water resistance, which can reduce the risk of short circuit in the system. In addition, the application of composite materials provides more room for integrated design, related enhancement components, add-ons, connection components, sensors, etc., can be integrated design, thereby improving the waterproof performance of the battery housing.

CONCLUSION

In summary, the choice of battery housing material for EPS cells depends on a variety of factors, including application, desired characteristics, and safety considerations.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

Negative electrode materials in EPS battery cell

negative electrode materials in EPS battery cell The negative electrode...

How is the superalloy spring designed in the battery safety valve?

How is the superalloy spring designed in the battery safety...

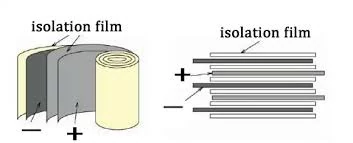

Isolation film material of EPS cell monomer: polymer

Isolation film material of EPS cell monomer: polymer In the...

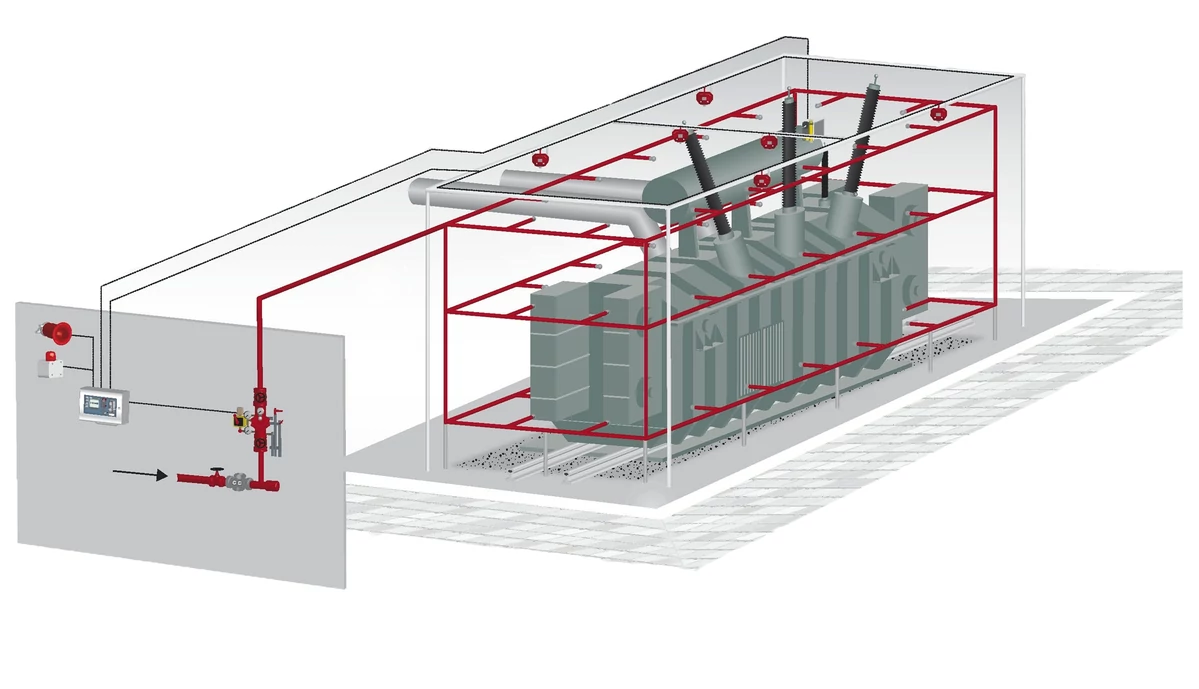

Detailed explanation of the transformer system of EPS inverter

Detailed explanation of the transformer system of EPS inverter In...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.