A highly integrated backup power solution for solar home energy...

Introduction to modified plastics in release buttons

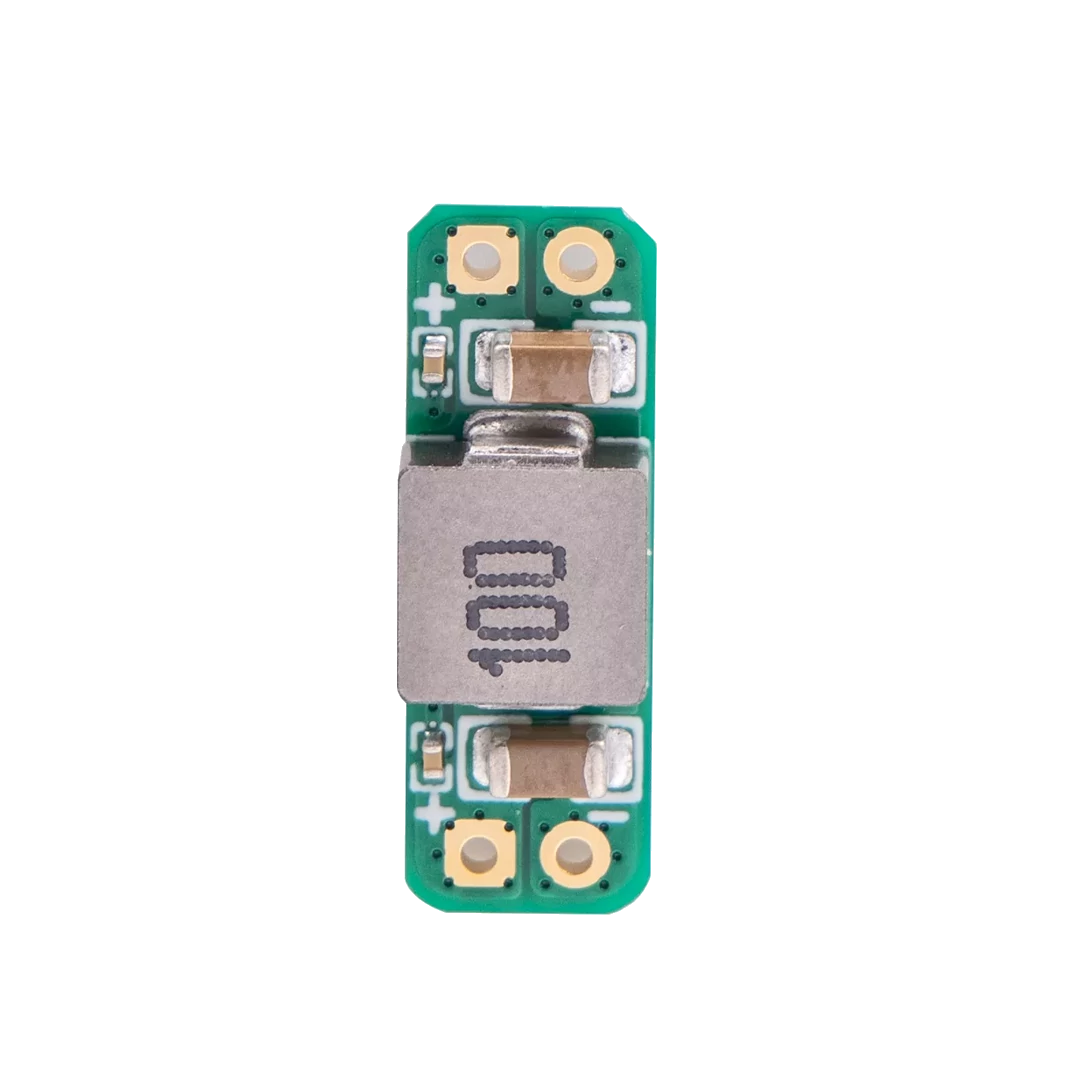

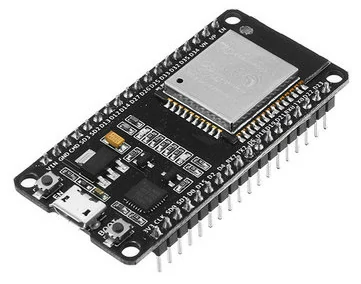

Main component

The release button is a key component in the gun head of DC charging pile, and its material selection has a direct impact on the performance and life of the button. Because of its excellent physical properties and processing properties, modified plastics have gradually become an important material in the manufacture of release buttons.

Modified plastics are materials obtained by physical or chemical modification of basic plastics (such as polypropylene, polycarbonate, etc.). Compared with unmodified plastics, modified plastics have significant improvements in strength, toughness, heat resistance, corrosion resistance and flame retardant. For example, modified polypropylene (PP) has higher impact strength and better temperature resistance, making it suitable for applications that require frequent operation.

In the release button, the use of modified plastics can effectively improve its comfort and response sensitivity. Due to its good flexibility and toughness, the button can withstand frequent pressing without deformation or fracture. This not only extends the service life of the button, but also enhances the user's operating experience.

In addition, modified plastics usually have good processability and are easy to be molded by injection molding, extrusion and other processes, making the production process more efficient and economical. Its diverse range of modification options also allows engineers to customize materials for different application needs to achieve the best performance and appearance design.

In short, modified plastics have become the ideal choice in the manufacture of release buttons because of their excellent performance and processing advantages, meeting the high requirements of modern electronic products for safety, durability and aesthetics.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

What is the effect of sheet molding plastic on the shell of DC charging pile?

What is the effect of sheet molding plastic on the...

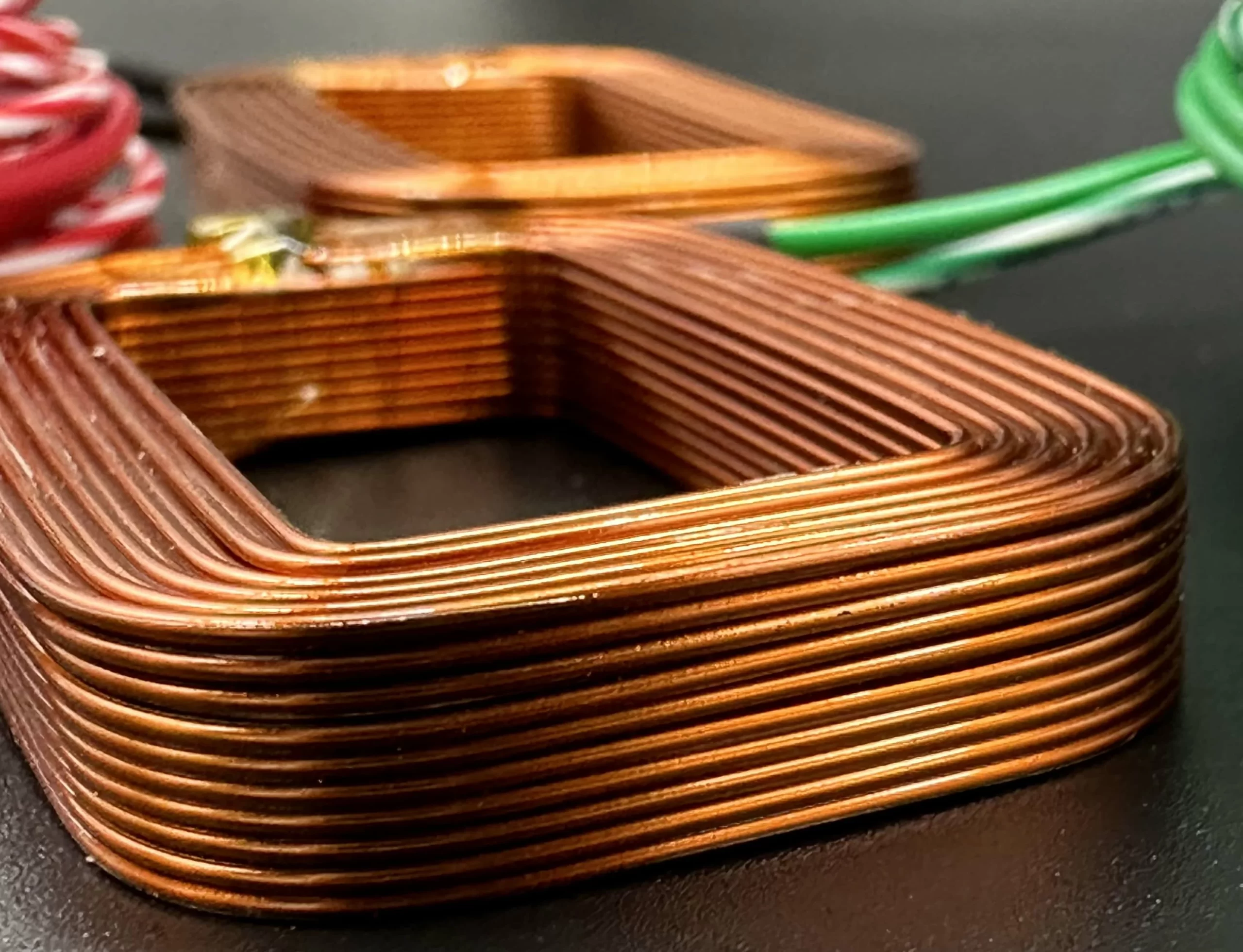

Introduction to DC charging pile transformer winding

Introduction to DC charging pile transformer winding The windings of...

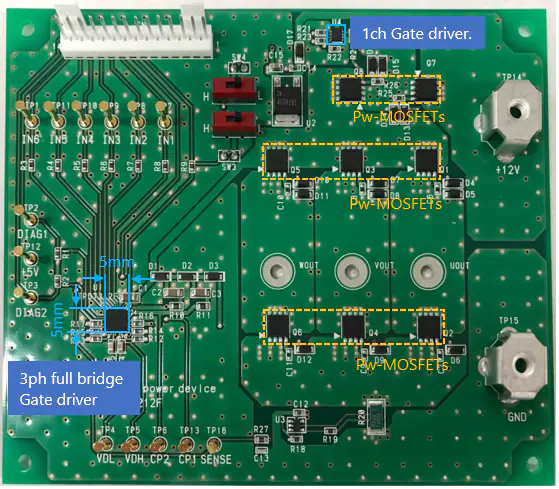

Dc charging pile display chip gate driver

Dc charging pile display chip gate driver Main component Concept:...

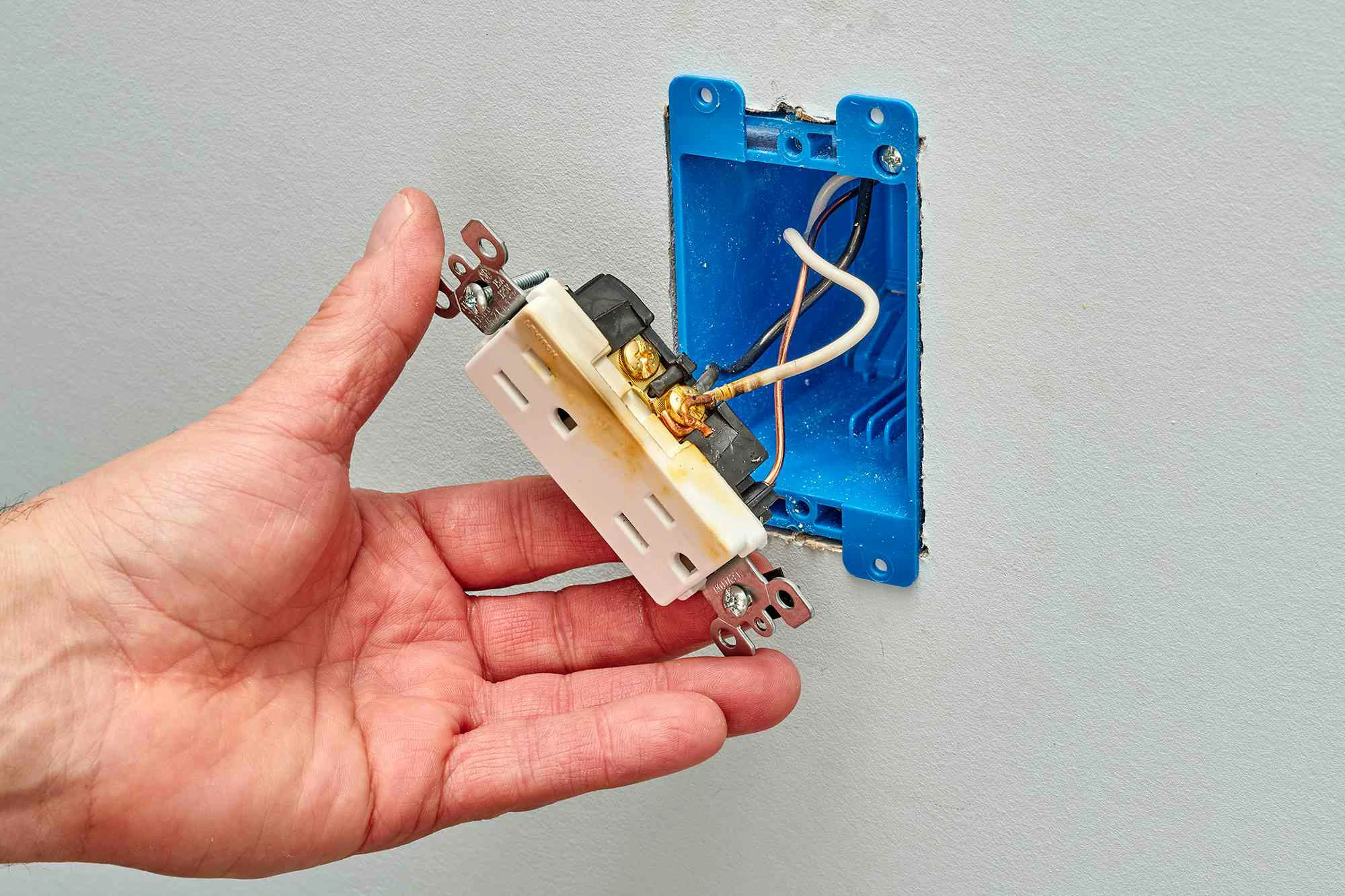

Introduction to short circuit protection of DC charging pile

Introduction to short circuit protection of DC charging pile Short-circuit...

Dc charging pile meter communication protocol support components

Dc charging pile meter communication protocol support components Main component...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.