Glass substrate in a display Main component Glass substrate is...

Introduction to grounding device of DC charging pile transformer

The grounding device of a DC charging pile transformer is a crucial component for ensuring the safe operation of the system. Here is a detailed introduction to these grounding devices:

Main component

Basic Structure and Features

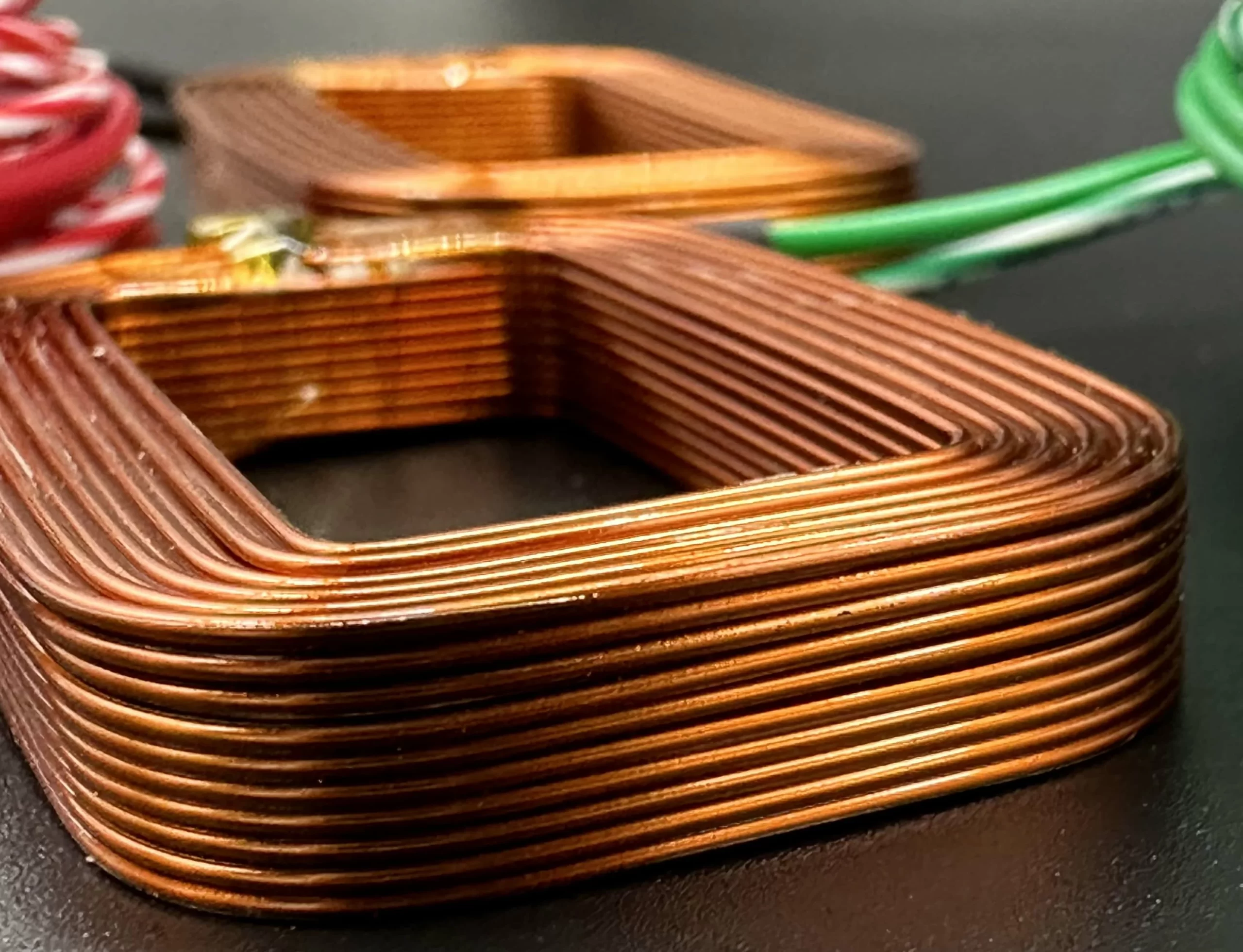

The basic structure of a grounding transformer is similar to that of a regular transformer, including a core, primary winding, secondary winding, and insulating materials. The core is made of silicon steel sheets stacked to reduce magnetic losses. The primary and secondary windings are connected to the high-voltage and low-voltage sides, respectively, and coupled through the core. Insulating materials are used to isolate the windings and core to prevent current leakage and insulation breakdown.

Working Principle

The working principle of a grounding transformer is to protect the system by grounding the neutral point of the high-voltage system. When a grounding fault occurs in the system, the grounding transformer directs the fault current to the ground to prevent the current from flowing to other components, causing more severe damage or personal injury. At the same time, the grounding transformer can provide a certain amount of short-circuit current to help quickly detect and isolate the fault point.

Device Classification

According to the different grounding methods, grounding transformers can be divided into neutral point grounding transformer, system grounding transformer, isolation grounding transformer and impedance grounding transformer. They are used to provide winding ground points for a system, to ground high-voltage windings in a system, for special occasions, and to limit the flow of fault currents by placing series impedances at neutral points .

Manufacturing Process

The manufacturing process of a grounding transformer includes design, material preparation, insulation treatment, assembly, and commissioning, as well as final inspection and packaging. Designers will develop a design plan for the grounding transformer based on the requirements and specifications of the power system, including determining the transformer's rated capacity, rated voltage, grounding resistance, and other parameters. Then, the required materials, including the core, winding wire, insulating materials, etc., are prepared and treated for insulation and assembled. Finally, electrical tests and commissioning are carried out to ensure that the performance of the grounding transformer meets the design requirements.

Wiring Methods

The wiring methods for grounding transformers mainly include star connection, delta connection, and Z connection. The star connection connects the neutral points of the three-phase windings together and then grounds them, suitable for low-voltage distribution systems. The delta connection connects the ends of the three-phase windings without grounding, suitable for high-voltage distribution systems. The Z connection grounds one end of the three-phase windings and connects the other end to the neutral point, forming a Z-shaped wiring method, suitable for medium-voltage distribution systems.

Grounding transformers are essential electrical equipment for protecting personal safety and facility equipment. They reduce the risk of electric shock and equipment damage by directing fault currents in the power system to the ground. With the development of power systems, the design and application of grounding transformers are also continuously advancing to meet higher safety and efficiency requirements.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Measurement and Calculation Unit of electric meter of DC charging pile communication charging module

Measurement and Calculation Unit of electric meter of DC charging...

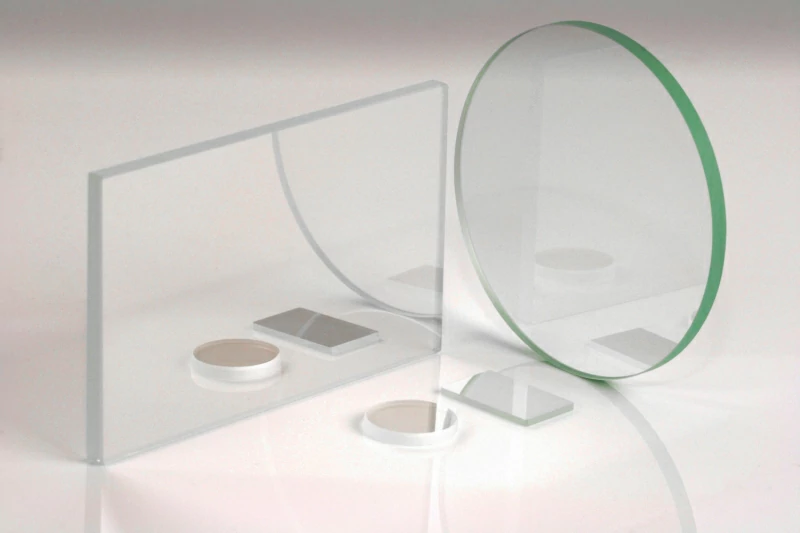

Metalized Polyimide Film in Grounding Contacts

Metalized Polyimide Film in Grounding Contacts Metalized polyimide films are...

Mobile Communication Module of DC charging pile charging control unit

Mobile Communication Module of DC charging pile charging control unit...

Introduction to DC charging pile transformer winding

Introduction to DC charging pile transformer winding The windings of...

The component of the electricity meter in the communication billing module

The component of the electricity meter The electricity meter in...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.