Shell switch of DC charging pile The shell switch of...

Introduction to DC charging pile transformer tank

The oil tank of a DC charging pile transformer is a crucial component of the transformer, playing a key role in protecting the internal components of the transformer and maintaining its normal operation. Here are the six main features and considerations for the oil tank:

Main component

Protection and Insulation

One of the primary functions of the oil tank is to protect the transformer's core and windings. It does this by being filled with transformer oil, immersing the core and windings within it, thereby isolating the insulation from the atmosphere, preventing the absorption of moisture and gases, and avoiding oil aging.

Cooling System

The heat generated by the transformer during operation needs to be effectively dissipated to prevent overheating and damage. The oil tank provides a space that can accommodate a radiator to cool the hot oil through the radiator and maintain the internal temperature of the transformer within a safe range.

Types of Oil Tank Structures

Common transformer oil tanks come in two basic types based on their capacity: box-type and bell-type. Box-type oil tanks are used for medium and small transformers, while large transformers typically use bell-type oil tanks.

Materials for the Oil Tank

The oil tank is generally made of hot-rolled steel plates not below Q235. The corrugated plates should be made of cold-rolled steel. These materials should have sufficient strength and rigidity to withstand the pressure inside the transformer and external loads.

Sealing and Anti-seepage

The structure of the oil tank needs to be sealed and leak-proof, and able to withstand a certain positive pressure. This includes the steel plate material and weld lines not leaking, as well as the mechanical connections being sealed without leakage.

Heat Dissipation and Strength

As the capacity of the transformer increases, the structure of the oil tank will also change to increase the heat dissipation area, such as adding heat dissipation flat tubes or designing the tank walls into a corrugated shape. At the same time, the oil tank should have sufficient mechanical strength to bear the weight of the transformer body, insulating liquid, and the overall lifting weight.

In summary, the oil tank of a DC charging pile transformer is responsible not only for containing and controlling the oil level but also for maintaining the oil temperature within a safe range through the cooling system, ensuring the stable operation of the transformer.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

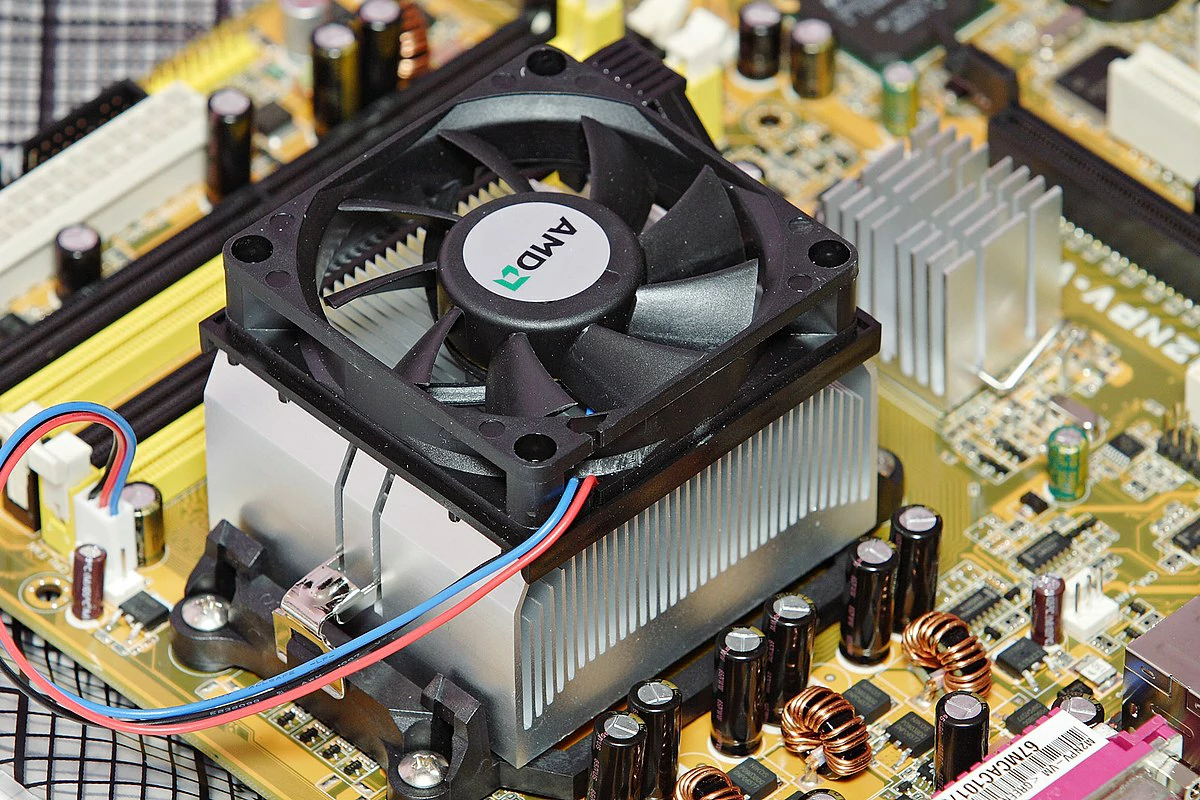

Introduction of fan in DC charging pile cooling system

Introduction of fan in DC charging pile cooling system In...

Introduction of fuses in DC charging pile rectifier

Introduction of fuses in DC charging pile rectifier The fuse...

Dc charging pile meter data processing and storage components

Dc charging pile meter data processing and storage components Main...

The component of the communication interface in the communication billing module

The component of the communication interface In the communication billing...

Locking pin and locking bolt of the gun head mechanical locking device

Locking pin and locking bolt of the gun head mechanical...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.