Introduction to the testing process of lithium iron phosphate monomer...

Introduction of the body material of the battery pack mechanical safety valve

The safety of the battery pack is very important, and the mechanical safety valve as a protective device can effectively prevent the danger caused by the internal gas overpressure. Therefore, the choice of valve body material plays a key role in the design of mechanical safety valves. In this paper, the valve body materials of battery pack mechanical safety valves will be discussed in detail, including their common material characteristics, selection criteria and performance in application.

the importance of valve body material

The valve body is the core component of the mechanical safety valve, which directly affects the performance, durability and safety of the valve. The choice of valve body material not only needs to meet the requirements of mechanical strength and pressure resistance, but also needs to have good corrosion resistance, temperature resistance and sealing performance to ensure that the valve can operate normally under various working conditions.

the importance of valve body material

Stainless steel

Characteristics: Stainless steel is a kind of alloy steel, the main composition of iron, chromium and nickel, with good corrosion resistance and high temperature performance.

Application: Widely used in the battery pack mechanical safety valve, can effectively resist the battery internal acid or alkaline gas may produce, maintain good sealing performance.

Pros: Corrosion resistance, high strength, long life, suitable for use in harsh environments.

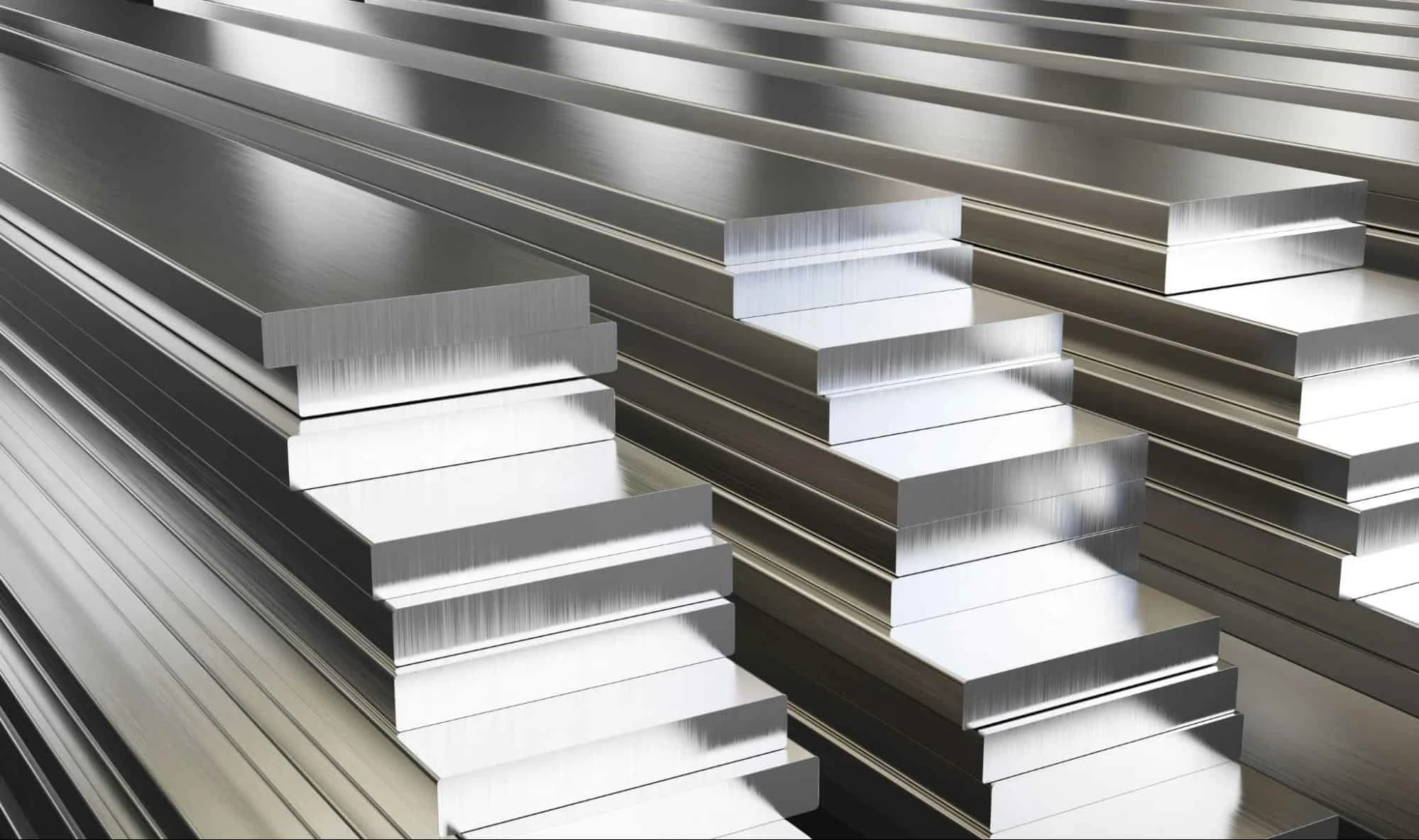

Aluminum alloy

Characteristics: Aluminum alloy with light, high strength and good processing performance, suitable for high design requirements of the valve body.

Application: Often used in smaller size battery pack safety valves, especially in portable equipment.

Pros: Lightweight, corrosion resistant, but not as adaptable as stainless steel in high temperature and high pressure environments.

Copper alloy

Properties: Copper alloys have excellent electrical conductivity and corrosion resistance. Tin, aluminum or other components are often added to improve their properties.

Applications: Mechanical safety valves for low pressure applications, especially those in direct contact with battery packs.

Applications: Mechanical safety valves for low pressure applications, especially those in direct contact with battery packs.

Polymer material

Characteristics: such as PTFE, PP and other materials, with good chemical stability and insulation performance.

Application: In some specific fields, especially special batteries or harsh environment, used for the sealing part of the valve body.

Pros: Light weight, excellent corrosion resistance, stable in a certain temperature range.

Material selection criteria

Resistance to corrosion

In the battery working environment, the internal and external environment may produce a variety of corrosion media, the choice of corrosion resistant materials can effectively extend the service life of the valve body.

High temperature and pressure resistance

In the process of battery use, especially in high-power discharge occasions, the internal temperature of the battery may rise rapidly, so the valve body material needs to have good high temperature resistance and high pressure ability.

Strength of machine

Mechanical safety valves need to withstand differential pressure and external forces in a variety of environments, so the mechanical strength of the valve body material is critical to ensure that it does not deform or break under working conditions.

Performance of sealing

The choice of material affects the fit and action of the seal to ensure that the valve will not leak when closed.

Performance in application

In practical applications, such as electric vehicles, energy storage systems, and portable devices, selecting the right valve body material can significantly improve the stability and reliability of mechanical relief valves. With the development of technology, advances in material science have also provided more options and possibilities for battery pack mechanical safety valves. New alloys and composite materials have been continuously developed to further optimize the performance characteristics of the valve.

Conclusion

The body material of the battery pack mechanical safety valve not only affects its safety and durability, but also directly relates to the overall performance and safety of the battery. In the process of material selection, it is necessary to consider multiple factors such as corrosion resistance, strength, temperature resistance and sealing performance. With the advancement of battery technology and the improvement of application demand, the study of new valve body materials will become an important direction of future battery safety valve design, which provides a solid foundation for achieving higher safety standards and performance.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Single cell internal resistance test

Single cell internal resistance test With the continuous development of...

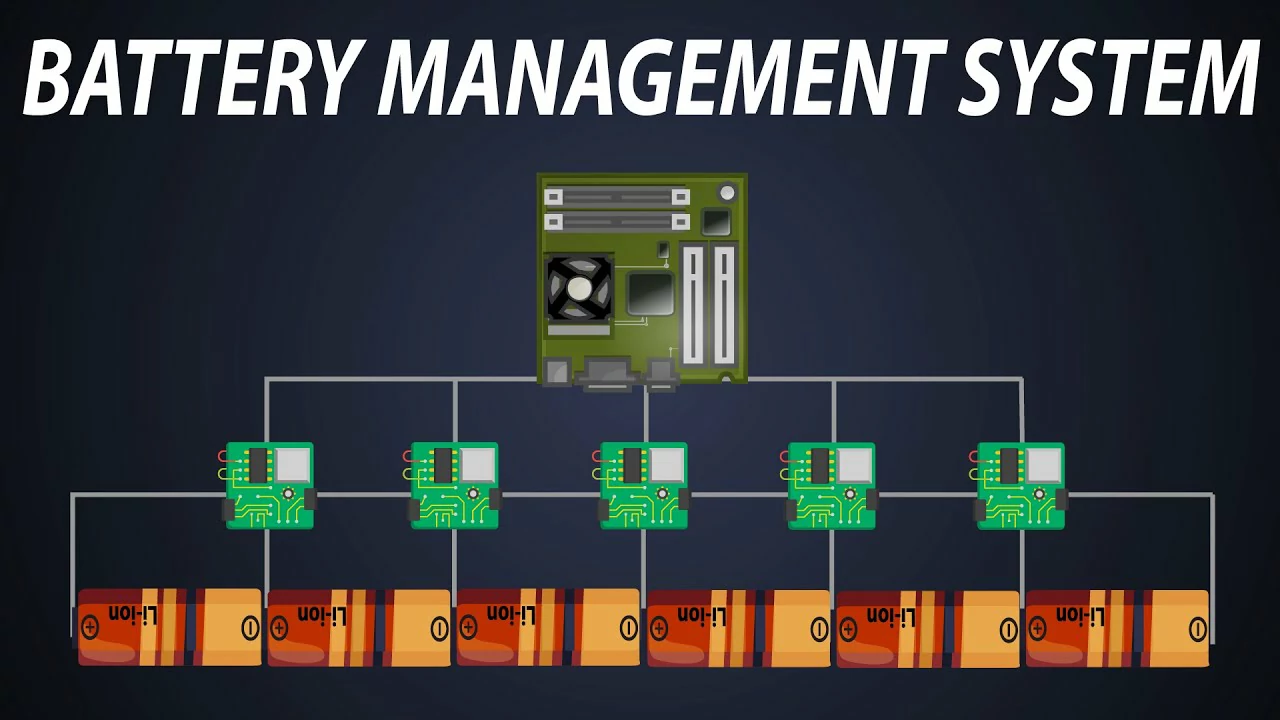

Distributed Battery Management System (BMS)

Distributed Battery Management System (BMS) With the widespread use of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.