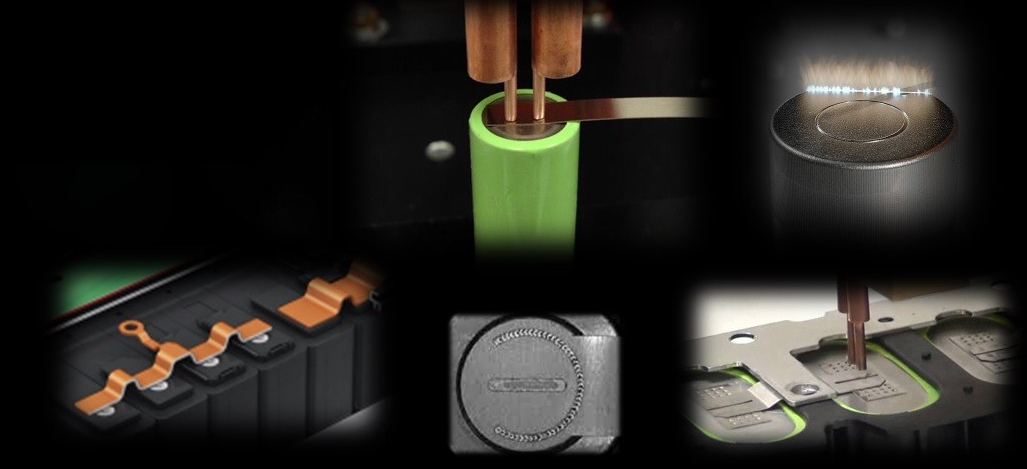

Product testing of welding terminals The quality of the soldered...

Introduction of sealing material for joint parts of battery shell

In modern battery design, the sealability of the joint part of the battery shell is very important. The seam is not only related to the performance and life of the battery, but also directly affects the safety of the battery. A good seal prevents moisture, dust, and other external contaminants from entering the battery interior and protects the core components of the battery. This article will introduce several commonly used battery shell joint sealing materials and their characteristics.

silicone sealant

Silicone sealant is a commonly used material in battery shell joint sealing, which has the following characteristics:

Excellent weather resistance: silicone sealant can withstand high temperature, low temperature and ultraviolet radiation, its chemical properties are stable, not easy to aging, to ensure long-term sealing effect.

Strong adhesion: silicone can form strong adhesion with a variety of materials (such as metal, plastic, etc.), suitable for a variety of battery material joints.

Elasticity and plasticity: silicone still maintains good elasticity after curing, and can adapt to the small deformation caused by temperature changes during the use of the battery.

Waterproof and DUstproof: the sealing layer formed by the material has good waterproof and dustproof performance, which effectively protects the inside of the battery from the external environment.

polyurethane sealant

Polyurethane sealant is commonly used for joint sealing of battery shell, and its characteristics include:

High elasticity and wear resistance: Polyurethane sealant has high elasticity, can well absorb shock and vibration, and also has excellent wear resistance.

Excellent chemical resistance: Polyurethane has good resistance to a variety of chemicals and can maintain stable performance in the battery working environment.

Excellent adhesion: Polyurethane can form a strong bond with a variety of substrates (such as metal, plastic, etc.) to ensure a reliable seal at the joint.

Weather resistance: polyurethane sealant is stable in extreme weather conditions, resistant to temperature changes and moisture.

epoxy resin

Epoxy is also a commonly used sealing material, especially in applications requiring high-strength sealing, with the following characteristics:

Strong adhesion: Epoxy resins can form strong bonds with a variety of substrates, providing long-lasting sealing properties.

High temperature resistance: CURED epoxy resin can withstand high temperature, suitable for high temperature conditions of battery applications.

Excellent chemical resistance: Epoxy resins have good resistance to a variety of chemicals and can protect the battery from corrosive substances.

Airtightness: The solid structure formed by epoxy resin after curing has excellent airtightness, which helps to prevent liquid and gas penetration.

foam glue

Foam glue is a lightweight sealing material, suitable for the joint part of the battery shell, with the following advantages:

Lightweight and flexible: Foams are lightweight and have good adaptability to fill seams and irregular surfaces of various shapes.

Cushions: Foam has good cushions that absorb vibrations and shocks, providing additional protection for the battery.

Simple application: Foam glue can usually be applied to the joint by simple coating or pressing method, convenient construction.

Water resistance: Most foams have good water resistance, which can effectively prevent the invasion of moisture and pollutants.

conclusion

The sealing material at the joint of the battery housing plays an important role in ensuring battery performance, safety and durability. Materials such as silicone, polyurethane, epoxy and foam have different characteristics to meet the needs of different battery designs and application environments. Choosing the right sealing material can not only improve the reliability of the battery, but also extend the service life of the battery. In the future development of battery technology, the innovation and improvement of sealing materials will continue to promote the development of the battery industry.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Battery sealing ring material

Battery sealing ring material With the rapid development of science...

Mechanical safety valve for the battery pack

Mechanical safety valve for the battery pack With the rapid...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.