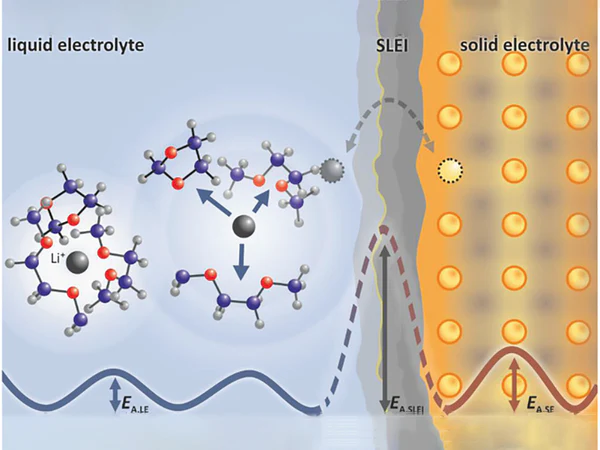

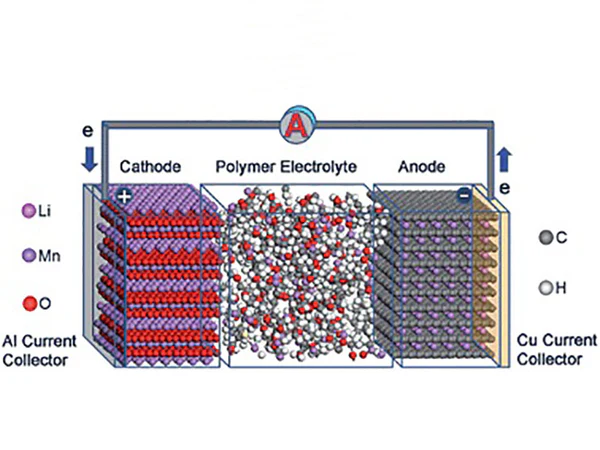

electrolytes of EPS battery cells In the EPS cell, the...

negative electrode materials in EPS battery cell

The negative electrode material of lithium-ion battery (EPS battery unit) is a key component of the battery, which directly affects the energy storage performance, cycle life and safety performance of the battery. The following are some common negative electrode materials and their characteristics in detail:

main content

Artificial graphite anode

The artificial graphite anode is a carbon material made by high temperature graphitization. It has a large number of pore structures, which is conducive to the penetration of electrolyte and the deimpingement of lithium ion. This material can improve the speed and frequency of rapid charging and discharging of lithium-ion batteries. Artificial graphite has the advantages that natural graphite does not have, such as long cycle, high temperature storage, and high rate, and is one of the main negative electrode materials used in power lithium batteries for new energy vehicles. Artificial graphite anode materials accounted for more than 60% of the market in 2016.

Graphitized mesophase Carbon microspheres (MCMB)

The negative electrode material of mesophase carbon microsphere is a small mesophase sphere obtained by special treatment of coal tar and made by high temperature graphitization. This material has the advantages of high electrode compaction density and high current fast charging and discharging performance. However, due to the high production cost and low capacity (320 ~ 350mAh/g), its use is limited.

Soft carbon

Soft carbon is a kind of non-graphitized carbon material with low crystallinity and high lithium storage capacity, but relatively poor cyclic stability.

Carbon Nanotubes (CNT)

Carbon nanotubes (CNTS) are special carbon materials with relatively complete graphitized structure, excellent electrical conductivity and high thermal conductivity. Carbon nanotubes have small depth, short travel, fast speed, and small polarization effect during large rate and large current charging and discharging, which is helpful to improve the high rate fast charging and discharging performance of lithium batteries. However, when used alone, there are some problems such as high irreversible capacity and low coulomb efficiency of first charge and discharge. Carbon nanotubes can be combined with graphite anode, silicon composite anode and other materials to improve the electrochemical performance of the original system of anode materials.

Graphene

As a cutting-edge carbon material, graphene has excellent electrochemical properties. Graphene has some excellent properties of both hard carbon and soft carbon negative electrodes, and shows excellent electrochemical characteristics of capacitors at voltages above 0.52V.

Lithium titanate (LTO)

Lithium titanate is considered to be a safer and longer-lived anode material than carbon. Lithium titanate has the advantages of fast charge and discharge, many cycles and high safety. Due to its "zero strain" performance, the cycle life of lithium titanate negative battery system can be greatly extended. However, the theoretical capacity of lithium titanate is low, only 175mAh/g, which limits its application in the field of power batteries.

Silicon negative and silicon carbon negative

Silicon anode is considered to be the ideal choice for the next generation of lithium-ion battery cathode due to its ultra-high specific capacity (3590mAh/g). Silicon anode material can greatly improve the energy density of lithium-ion batteries, but its low cycle life and huge volume expansion are the main obstacles to commercial application. The silicon carbon anode combines the advantages of silicon and carbon to improve the energy density and cycle stability of the battery.

CONCLUSION

The selection and application of these anode materials have their own advantages and limitations according to different application scenarios and performance requirements. With the continuous advancement of battery technology, research and development of negative electrode materials are also ongoing to meet the needs of higher energy density, longer life and higher safety.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

This section describes the wireless interface of the EPS

This section describes the wireless interface of the EPS In...

This section describes the components of the EPS wireless interface

This section describes the components of the EPS wireless interface...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.