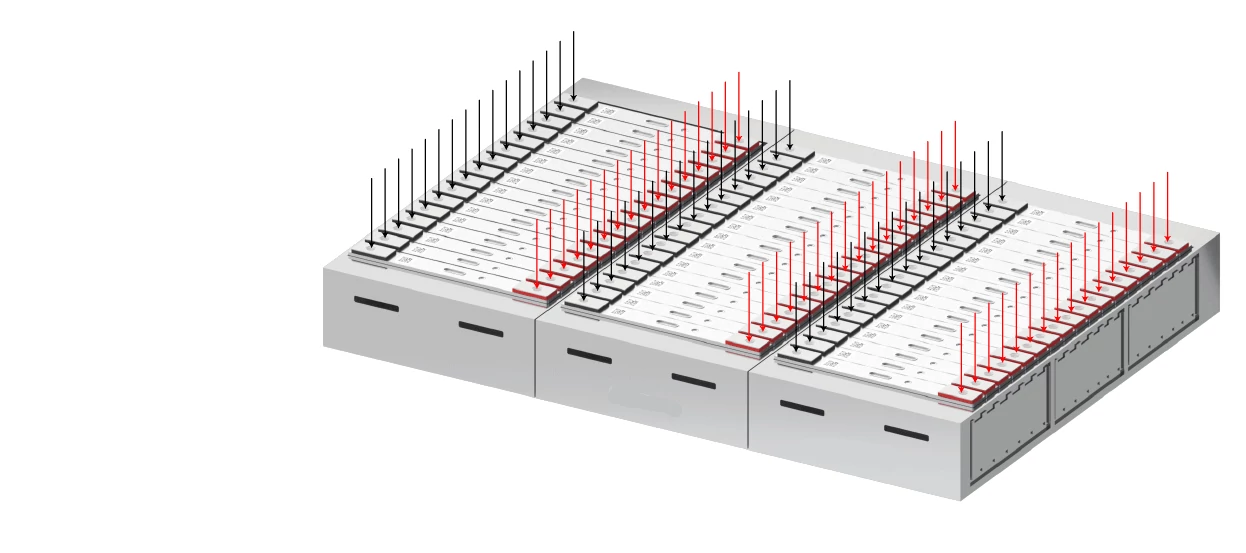

Partition Capacity separation is a key step in the production...

Inject liquid

Battery manufacturing injection refers to the process of controlling the amount of liquid electrolyte and injection time, so that the liquid electrolyte is injected into the battery from the injection port. Its main purpose is to form ion channels to ensure that enough lithium ions migrate between the positive and negative electrode plates during the charging and discharging process of the battery to achieve a reversible cycle.

main content

The battery injection process usually includes the following steps:

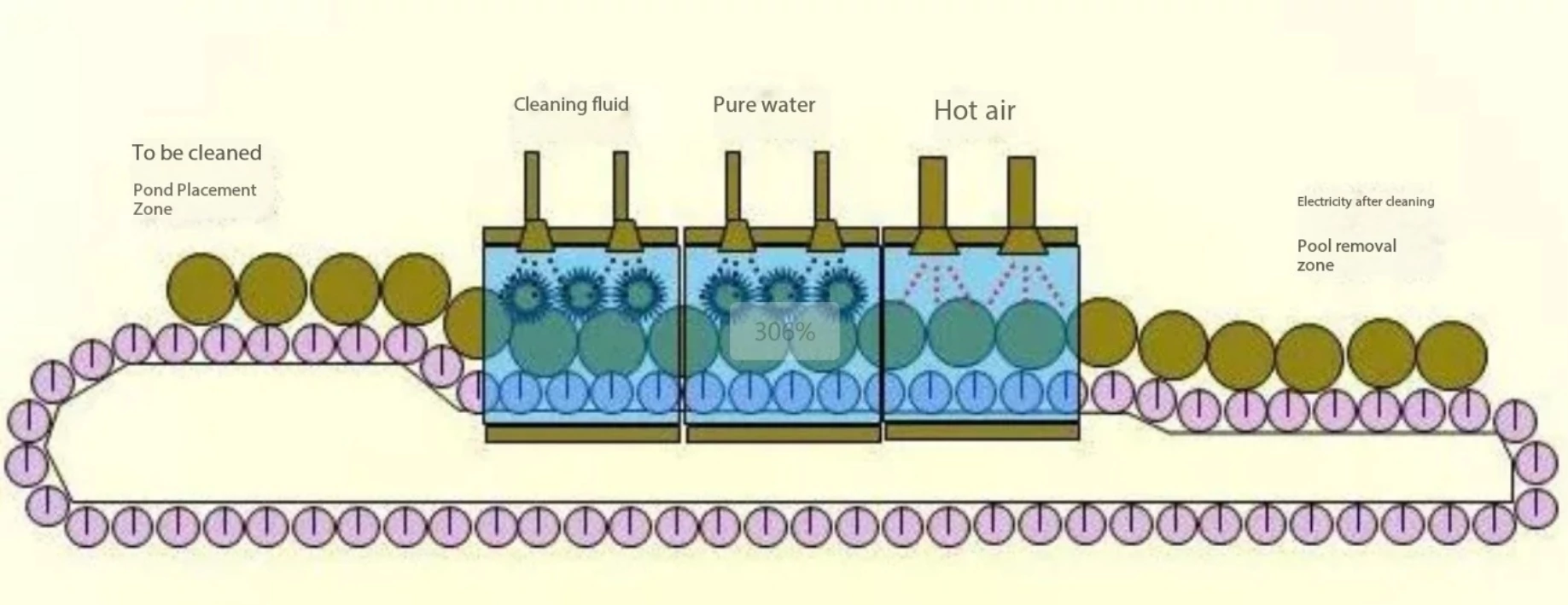

Pretreatment

Prepare the battery and liquid injection material, select the appropriate volume and proportion. Clean the battery to ensure that the battery is free of impurities and residual electrolyte. Charge the battery to reach a certain level of charge.

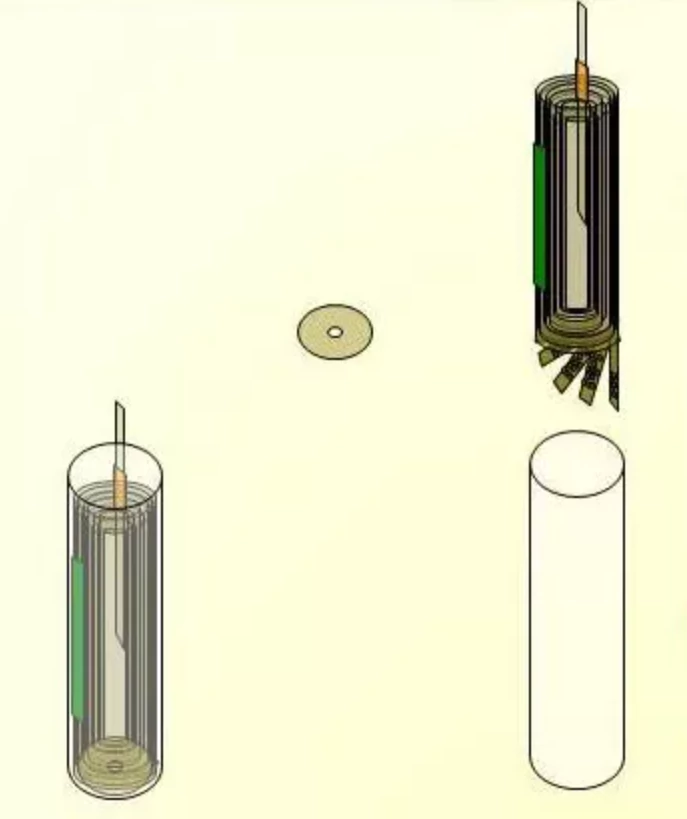

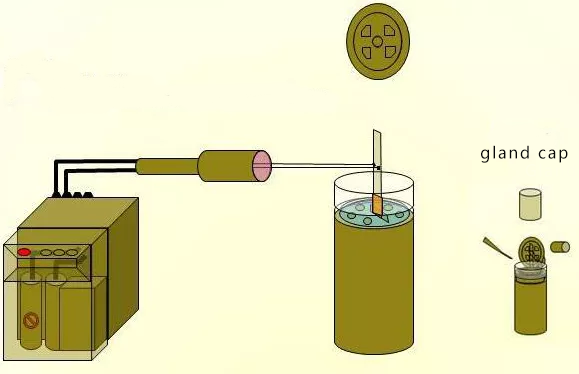

Liquid Injection

Clean the injection tool and prepare the injection material.

Control the amount and speed of liquid injection to avoid too much or too little. Pay attention to avoid bubbles during liquid injection. The liquid injection material can be placed in advance for a period of time to allow it to remove bubbles naturally.

After the injection, pay special attention to the cleaning of the mud plug to avoid blocking the injection hole.

Place

After injection, the battery is placed for a period of time to allow the injection to fully penetrate into the battery. The storage time depends on the type of battery and the amount of liquid injected, usually between 2 and 4 hours. Control the temperature and environment during storage to avoid too high or too low temperature.

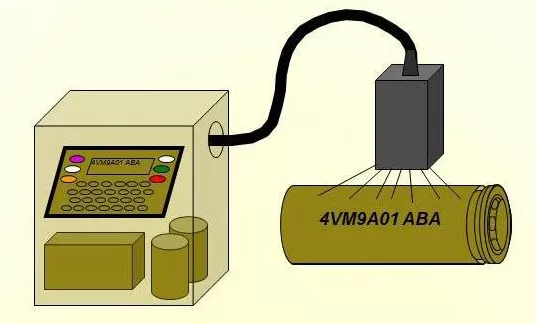

Detection

Test the battery after placement to ensure that the liquid injection quality is good. The detection content mainly includes battery power, battery voltage, battery temperature and other parameters. If the quality of the injection is found to be defective, it is necessary to re-inject the liquid.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.