EPS inverter DC input part analysis – battery input terminal...

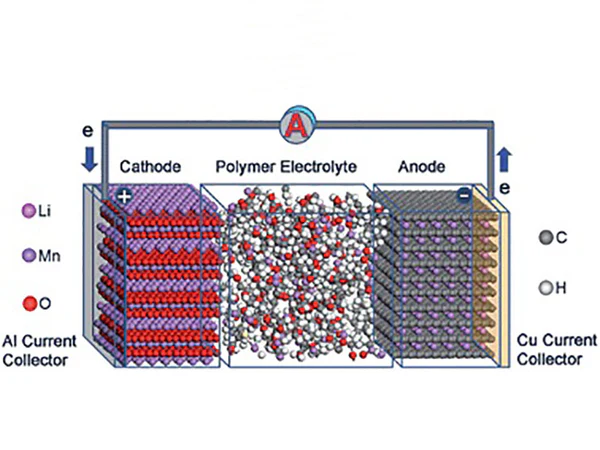

How can composite materials improve performance in battery electrode collector?

The application of composite materials in the battery electrode collector can significantly improve the performance of the battery, the following are several key aspects.

main content

Improve safety performance

Composite fluid collector, such as PET-AIOX-AL composite fluid collector, can improve the binding force of metal aluminum and polymer substrate by composite alumina and silicon oxide coating on PET polymer substrate as a strengthening layer. The introduction of this strengthening layer does not affect the surface square resistance of the aluminum layer, which ensures the normal use of the composite fluid collector in the battery. In the acupuncture test, the battery using the PET-AIOx-Al composite fluid collector showed better safety performance than the battery using the traditional Al fluid collector, no fire and smoke phenomenon, and effectively prevented the internal short circuit of the battery.

Enhance mechanical properties

The mechanical properties of composite fluid collectors, such as PET-Cu composite fluid collectors, are critical to ensuring their reliable operation. By means of finite element simulation and digital image correlation techniques, the tensile properties of the PET-Cu composite collector at different directions, strain rates and sample geometries were studied. These results provide theoretical basis and reliability proof for the practical application of composite fluid collector.

Improve electrochemical performance

Composite fluid collectors can enhance their electrical conductivity and corrosion resistance through coating technology. For example, Huang et al. coated the conventional aluminum foil of lithium-sulfur batteries with graphene-carbon nanotube composite coating, and the introduction of this composite coating increased the interface adhesion and electrical conductivity between the collector and the active layer, significantly improving the electrochemical performance of the battery.

Improve electrolyte compatibility

By introducing strengthening layers, such as alumina and silicon oxide, the composite fluid collector can significantly increase the surface roughness of the polymer substrate and provide interfacial chemical bonding, thereby improving the bonding force between the polymer substrate and the aluminum layer. This increase in binding force is conducive to the resistance of the composite collector to the erosion of the electrolyte, showing better electrolyte compatibility.

Improve battery rate performance and cycle stability

Composite materials that collect fluids, such as MOFs-based composites, exhibit good cyclic stability. For example, Li et al used MIL-88-FeFeC2O4∙2H2O as a precursor to prepare C-Fe3O4 microspheres for lithium battery negative electrodes, and the composite maintained a high discharge capacity of 975 mA∙h/g after 50 cycles of testing.

Promote lithium ion transmission and distribution

The PC-Cu composite fluid collecting nanostructured Cu layer can provide abundant nucleation sites, reduce overpotential and local current density during lithium deposition, and achieve uniform lithium nucleation and dense lithium deposition. In addition, the high toughness of PASC enables effective stress dissipation to adapt to volume changes during lithium deposition, enabling dense and uniform lithium deposition even under high magnification conditions.

CONCLUSION

In summary, the application of composite materials in the battery electrode fluid collector can improve the overall performance of the battery by improving safety performance, enhancing mechanical properties, improving electrochemical performance, improving electrolyte compatibility, and facilitating the transmission and distribution of lithium ions.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

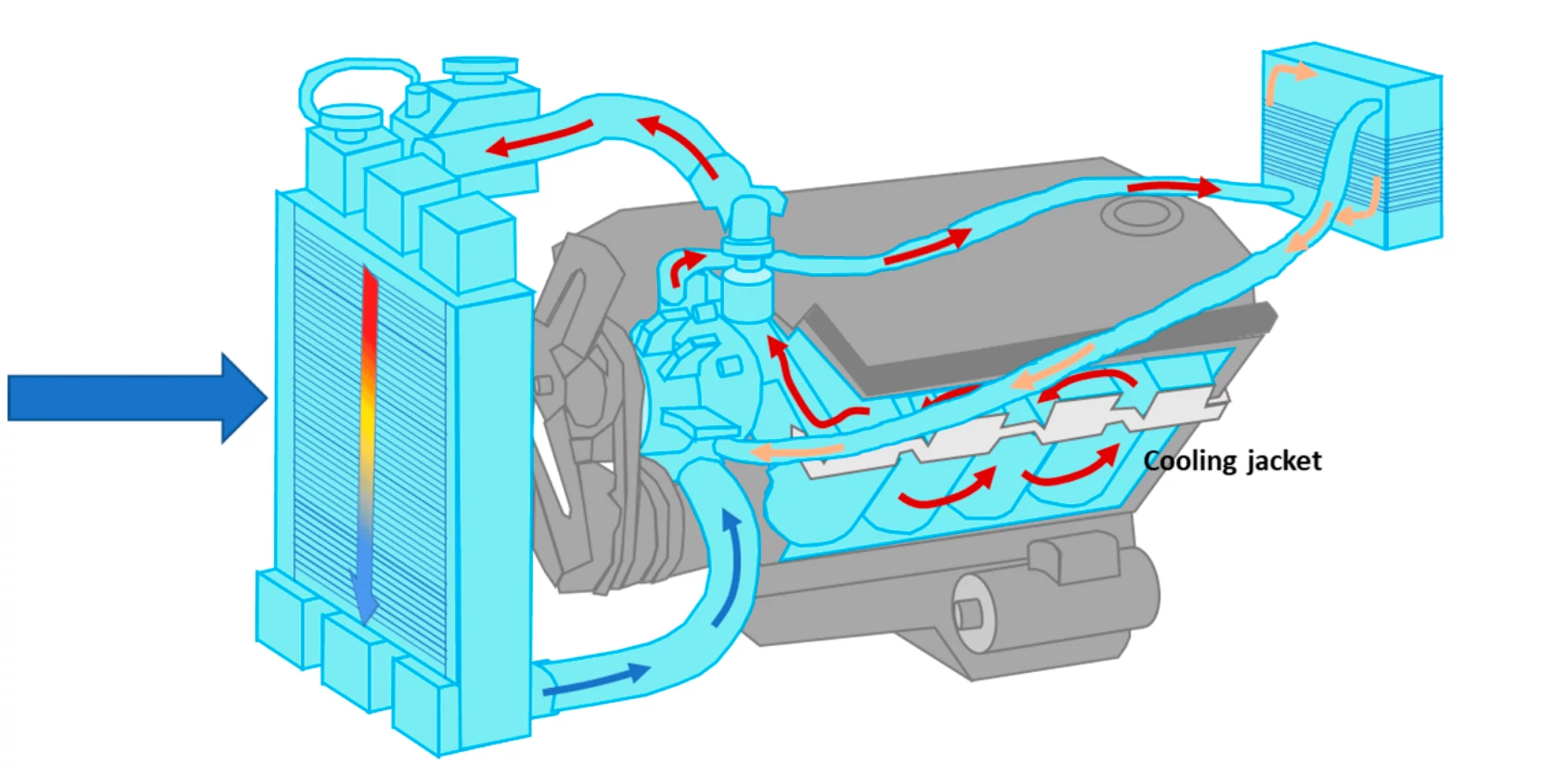

Introduction of cooling pump in EPS cooling system 1

Introduction of cooling pump in EPS cooling system 1 In...

Battery cell – lithium-ion battery

Battery cell – lithium-ion battery Lithium-ion batteries are one of...

Control system analysis – control algorithm

Control system analysis – control algorithm The control algorithm is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.