User guide The use guide for tower backup energy storage...

Housing material

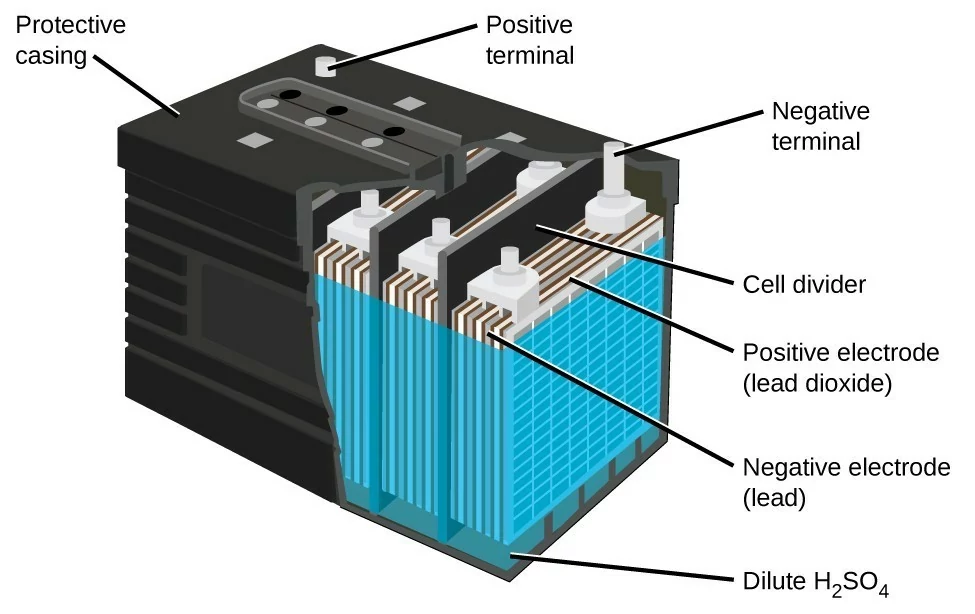

The shell material is an important part of the tower backup energy storage battery, which is mainly responsible for providing physical protection for the battery, preventing the external environment from damaging the internal components of the battery, and ensuring the structural stability of the battery. The shell should not only meet the protection function, but also have certain corrosion resistance, strength and good thermal conductivity.

Housing material

Battery shell material is an important protective layer for energy storage battery systems, which not only has excellent mechanical strength, corrosion resistance and thermal management performance, but also needs to take into account weight, cost and safety. Aluminum and stainless steel are common materials for applications that require strong protection and durability; Engineering plastics and composites are suitable for scenarios where lightweight requirements are high. By selecting the appropriat e housing material, the safety, stability and service life of the battery can be effectively improved.

Detailed information

Main material type

Aluminium alloy

Features: Aluminum alloy material has light weight and good mechanical strength, and has good corrosion resistance.

Advantages: The aluminum alloy shell has excellent thermal conductivity, which helps the battery heat dissipation, and can effectively extend the service life of the battery due to its excellent oxidation resistance.

Application: Often used in high-end energy storage systems, suitable for scenarios requiring strong durability and heat dissipation.

Stainless steel

Features: Stainless steel has stronger corrosion resistance and higher strength, suitable for energy storage systems in harsh environments.

Advantages: The stainless steel housing provides additional physical protection, especially in high temperature, high humidity or corrosive environments.

Application: Suitable for industrial, offshore or extreme environment energy storage equipment.

Engineering plastics

Features: Engineering plastic is a lightweight, durable material with good chemical resistance and insulation properties.

Advantages: The engineering plastic shell can effectively reduce the overall weight of the battery, but also has a certain impact resistance, suitable for low temperature environment.

Application: For low-power energy storage devices or scenarios where battery weight needs to be reduced. Common materials are polycarbonate (PC) and polypropylene (PP).

Composite material

Features: Composite materials are usually composed of a variety of materials (such as carbon fiber, glass fiber, etc.), with excellent mechanical properties and lightweight characteristics.

Advantages: Composite housing can be strong and light at the same time, and has excellent temperature and corrosion resistance.

Application: Used in high-end application scenarios, such as electric vehicles, electric energy storage and other fields.

Performance requirement

Corrosion resistance

The battery case needs to have good corrosion resistance to prevent rust or damage in wet or chemically aggressive environments. Aluminum alloy and stainless steel usually have strong corrosion resistance and can adapt to harsh environments.

Mechanical strength and impact resistance

The housing material needs to be mechanically strong enough to withstand external shocks and pressures and avoid damage to the battery's internal components. High-strength materials such as stainless steel, composite materials and aluminum alloys provide strong physical protection.

Thermal management performance

The thermal conductivity of the housing material is very important for the heat dissipation performance of the battery. The high-quality housing material can effectively help the battery heat dissipation and maintain the normal working temperature of the battery. Aluminum alloy is more excellent in this respect and can effectively dissipate heat.

Weight and cost

The weight of the housing affects the convenience of the overall system, especially in mobile applications (such as electric vehicles). Lightweight enclosures such as engineering plastics and composite materials can effectively reduce weight. In addition, the cost of housing materials directly affects the manufacturing cost of energy storage equipment.

Function and effect

Physical protection

The housing provides a strong physical barrier to the battery, protecting it from external shocks, impacts, pressure, or other factors that may cause damage. A good housing design can avoid battery failure or safety issues caused by external damage.

Safety isolation

The housing also acts to protect the battery's internal circuitry and chemical leaks, preventing the risk of fire or explosion. The tightness of the housing also prevents the leakage of harmful gases or liquids.

Thermal management

The shell can effectively help the battery system heat dissipation, keep the battery within a reasonable operating temperature range, and avoid battery performance degradation or safety accidents caused by overheating. Some enclosures are also designed with heat dissipation holes or fins to further enhance the heat dissipation effect.

External access protection

The housing is also usually designed with an access port or interface to protect the battery from danger or interference caused by external contact during charging and discharging.

TOWER BACKUP BATTERY

With its integrated structural design, intelligent BMS monitoring, and standardized cabinet installation, ESS 48V series lithium iron phosphate batteries can provide reliable backup power for access network equipment, remote exchange, mobile communication, transportation equipment, emergency power and other systems.

Extended reading

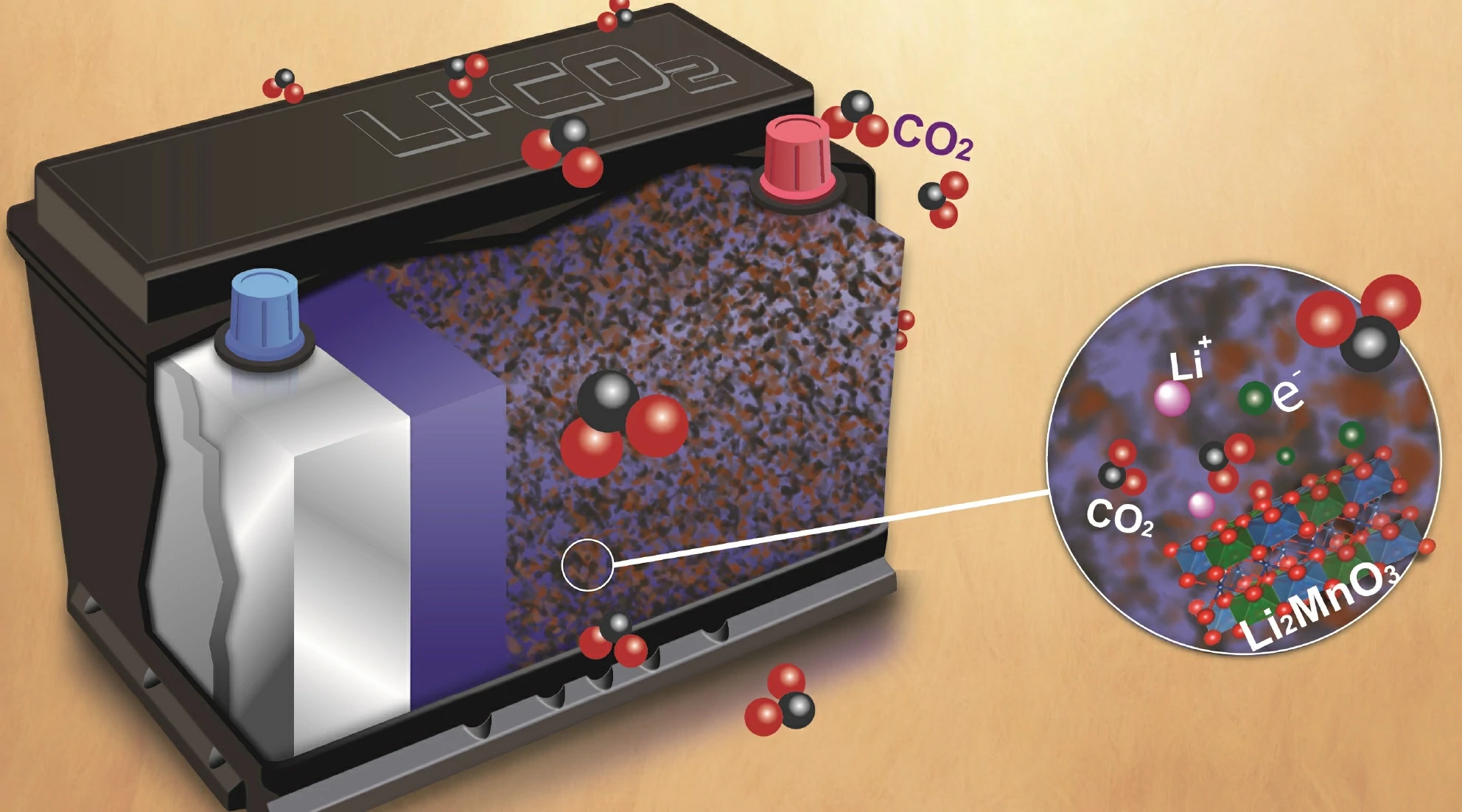

Working principle and process flow

Working principle and process flow The working principle of the...

Product update direction and recycling

Product update direction and recycling The product update direction of...

Application scenario

Application scenario The application scenario of tower backup energy storage...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.