Battery pack energy rating The rated energy of a battery...

High and low temperature test of single cell

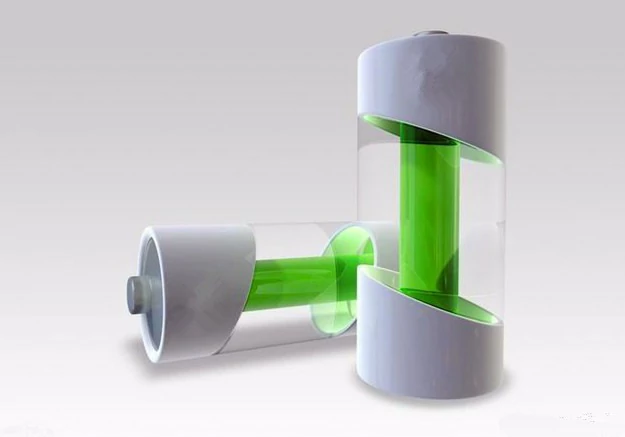

In the wide application of modern electronic devices and electric vehicles, the stability of the performance of the single cell battery is crucial as the main energy storage device. Tests in both high and low temperature environments can help assess the adaptability and safety of batteries in extreme temperature conditions. This article will introduce the operation process of high temperature and low temperature test of single battery, the required instrument and the matters needing attention.

the purpose of high temperature and low temperature testing

Safety assessment: Testing the safety of the battery in extreme temperatures to prevent dangerous situations such as thermal runaway, leakage and fire.

Performance stability: evaluate the charging and discharging performance of the battery under high or low temperature conditions to ensure the reliability of the product in actual use.

Compliance: Ensure that batteries comply with relevant industry standards and safety regulations, and provide a basis for market access.

Cycle life: Through the temperature stress test, the cycle life and service performance of the battery are evaluated.

the basic principle of high temperature and low temperature test

High temperature test: test the working performance and safety of the battery in a certain high temperature environment. High temperature will accelerate the internal chemical reactions of the battery, which may lead to decreased battery performance, shortened life and even safety risks.

High temperature test: test the working performance and safety of the battery in a certain high temperature environment. High temperature will accelerate the internal chemical reactions of the battery, which may lead to decreased battery performance, shortened life and even safety risks.

Operation process of high temperature and low temperature test

Preparation Phase

Ensure that the testing area meets the safety requirements, and prepare the required test instruments and equipment.

Equipment selection and preparation

Select the appropriate high and low temperature box (temperature control box), can achieve high temperature (such as 60°C above) and low temperature (such as -20°C or lower) environment stable control.

Select the appropriate high and low temperature box (temperature control box), can achieve high temperature (such as 60°C above) and low temperature (such as -20°C or lower) environment stable control.

Connect the battery

Install the single battery to be tested into the test equipment to ensure that the battery is in good contact with the test environment and can effectively feel the environmental temperature change.

Set the test conditions

For high temperature test, set test temperature, duration, etc. For the low temperature test, the corresponding conditions are also set.

Typically, the test duration can be set from several hours to several days, depending on the battery type and test requirements.

Test it

Start the high and low temperature box and place the battery in the set temperature environment.

During the test, the battery is charged and discharged cycle, the voltage, capacity, temperature and other indicators of the battery are monitored, and the data are recorded.

Monitor and record data

Start the high and low temperature box and place the battery in the set temperature environment. During the test, the battery is charged and discharged cycle, the voltage, capacity, temperature and other indicators of the battery are monitored, and the data are recorded.

End the test

After the test, the battery was gradually restored to the normal temperature environment. Avoid rapid cooling to avoid thermal shock damage to the battery.

Perform a visual inspection of the battery to see if there is swelling, leakage, or other abnormalities.

Data analysis and report

The data recorded during the test were collected and analyzed to evaluate the performance changes of the battery in high and low temperature environments.

Write test reports to identify battery performance in extreme temperatures and possible safety hazards.

Required instruments and equipment

High temperature and humidity test box

Can accurately control the high temperature and low temperature environment equipment, suitable for single battery performance test.

Data logger

It is used to record the voltage, temperature and capacity data in the process of charging and discharging in real time to ensure the integrity and accuracy of the data.

Battery Tester

An instrument used to measure battery capacity, internal resistance and other electrical properties.

Temperature sensor

Monitor the temperature changes on the battery surface and inside the test chamber to ensure the accuracy of the test.

Safety protection facilities

Protective glasses, insulated gloves and fire protection equipment are included to ensure the safety of operators during testing.

Precautions

Safety first:

During the test, it is necessary to pay close attention to the temperature and state of the battery, and deal with the abnormal situation in time to ensure the safety of the operator.

Gradual temperature change:

When performing high or low temperature tests, avoid rapid changes in case the battery material is damaged due to thermal stress.

Calibration of test equipment:

Ensure that the temperature control equipment and monitoring instruments have been calibrated before testing to ensure that the test data is accurate and reliable.

Environmental Control:

The test environment should be kept stable to avoid the influence of external temperature and humidity changes on the test results.

Waste Disposal:

After the test, properly dispose of damaged or leaked batteries and follow the relevant environmental regulations.

Conclusion

High and low temperature testing is a key step to evaluate the performance and safety of single cell batteries in extreme environments. Through the strict test process and professional test equipment, the potential problems of the battery in the process of temperature change can be effectively found, and provide a basis for product improvement. Ensuring the scientific and safety of the test can not only improve the performance and reliability of the battery, but also provide a solid guarantee for its application in the market.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Manufacturing process of lithium battery diaphragm

A highly integrated backup power solution for solar home energy...

The main function of the battery shell of lithium iron phosphate monomer battery

The main function of the battery shell of lithium iron...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.