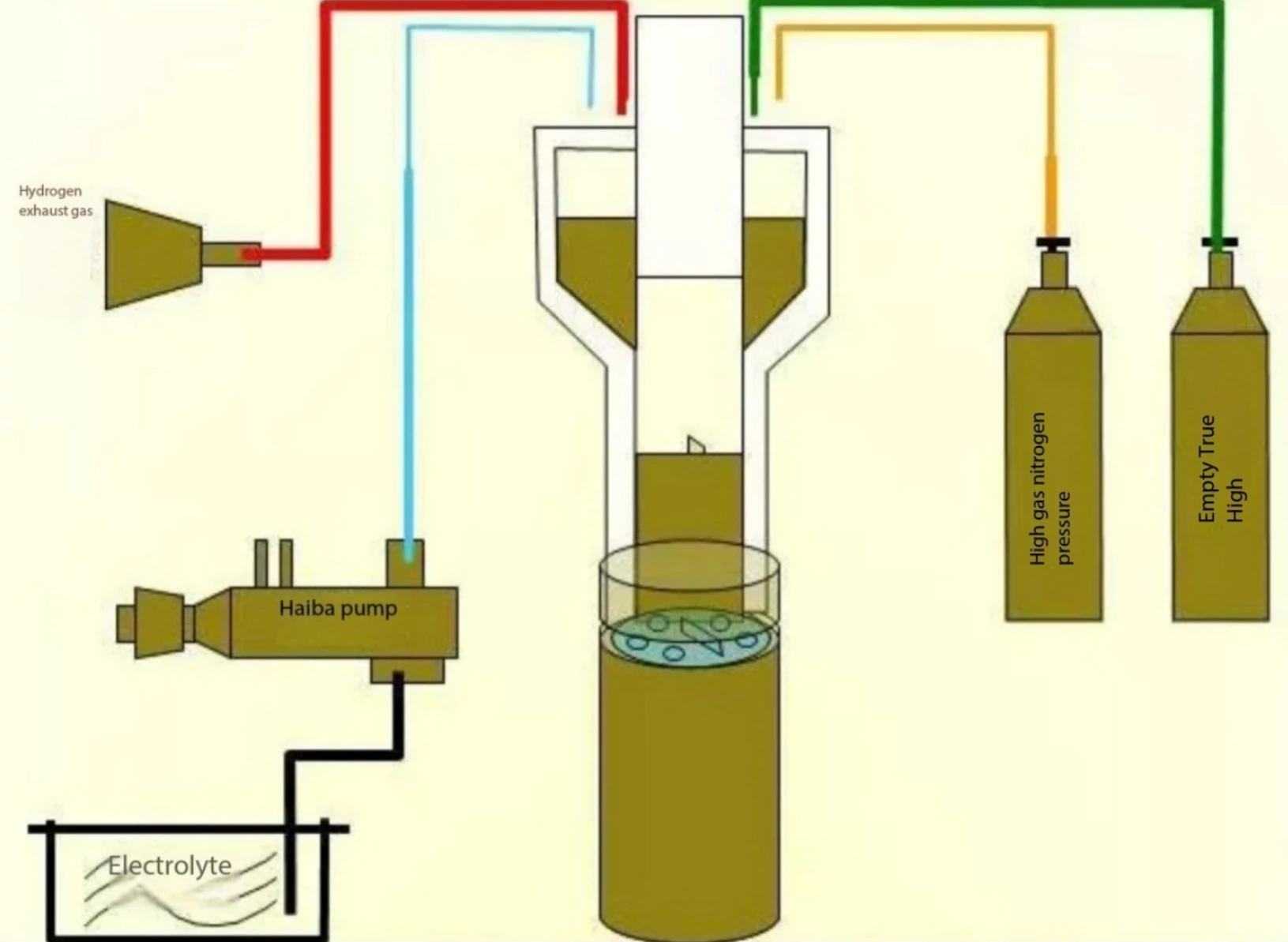

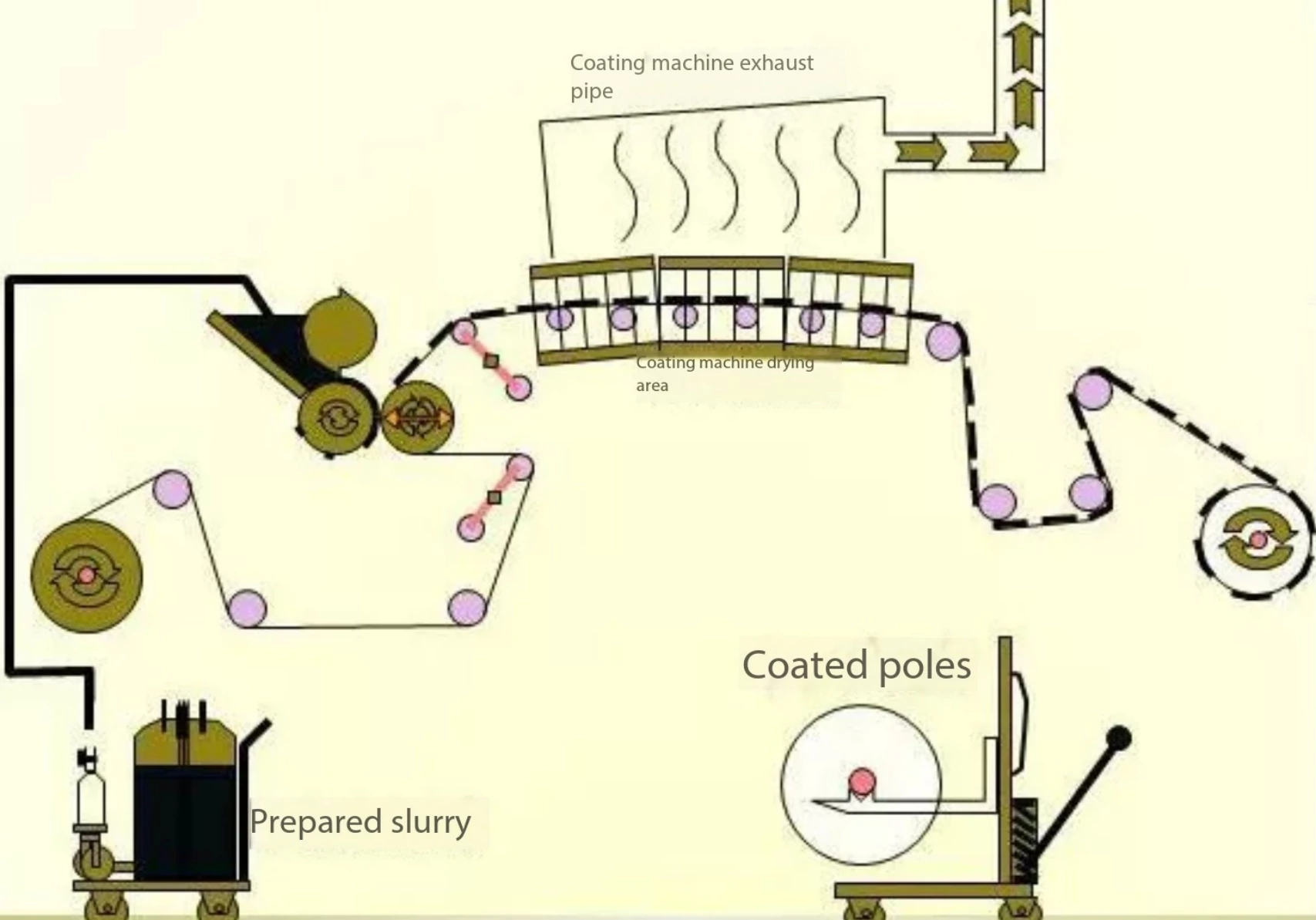

Inject liquid Battery manufacturing injection refers to the process of...

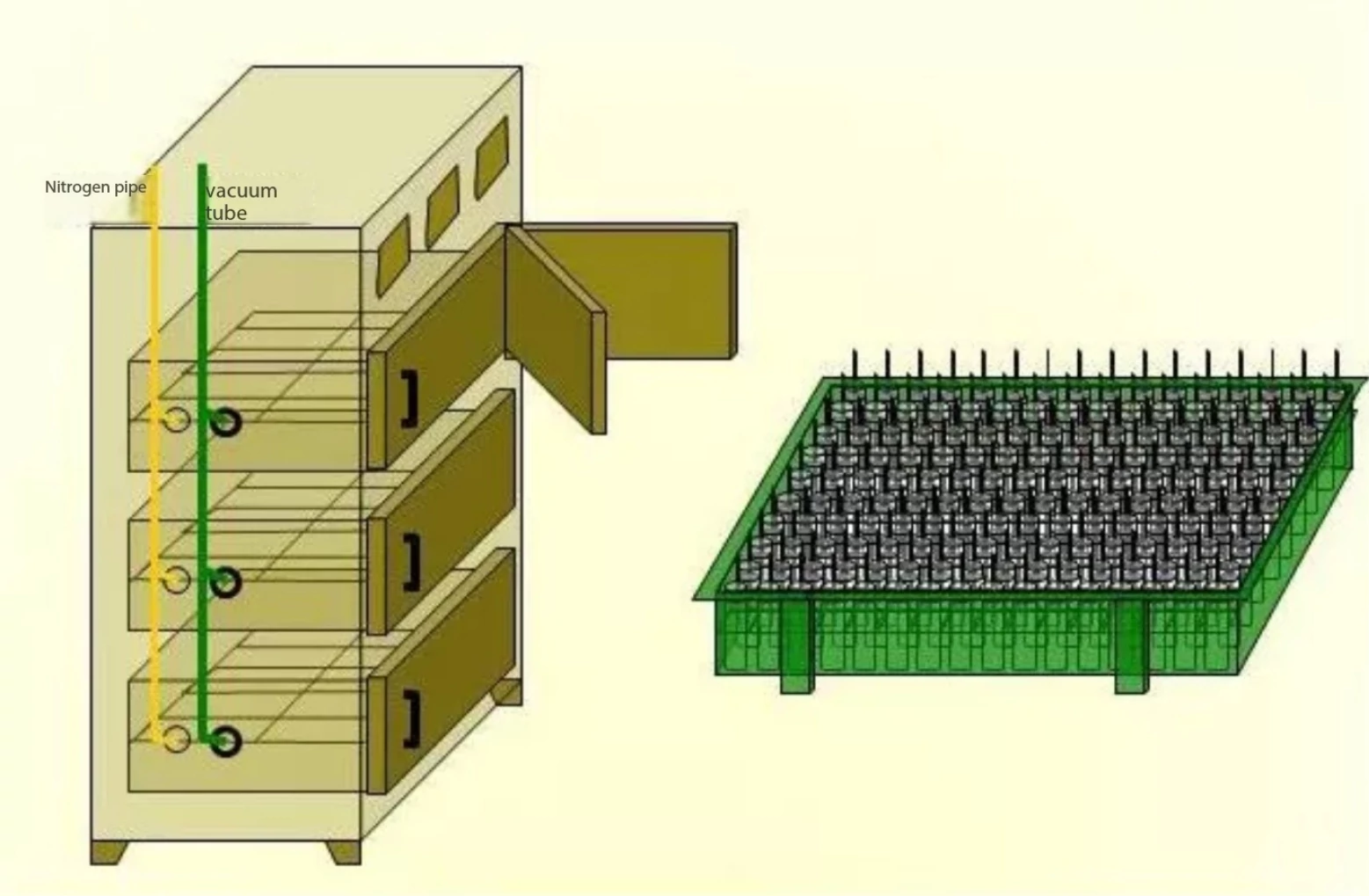

Formation

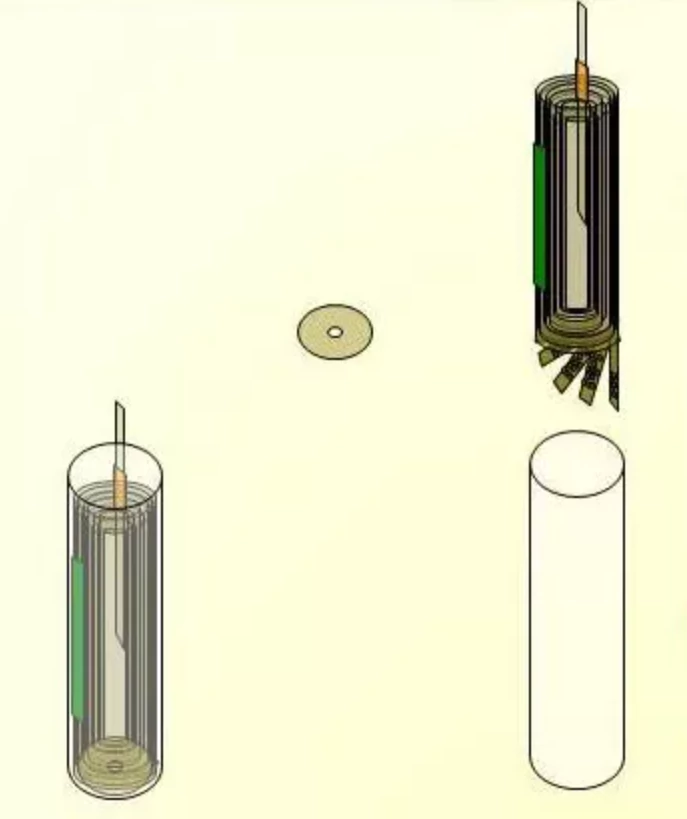

Formation is a crucial step in the production process of lithium batteries, which involves the first charging of the battery after liquid injection to activate the active substances in the battery and form a solid electrolyte interface (SEI) film. The following is a detailed description of the formation process:

The purpose and importance of formation

The main purpose of the formation process is to activate the positive and negative materials inside the battery by a certain way of charge and discharge, and improve the battery's charge and discharge performance and self-discharge, storage and other comprehensive performance. During the formation process, the lithium ion will undergo an electrochemical reaction in the battery when it is charged for the first time, forming a passivation thin layer covering the surface of the carbon electrode at the phase interface between the negative carbon electrode and the electrolyte, that is, the SEI film. SEI film formation has a great impact on battery cycle life, initial capacity loss, rate performance and so on.

Formation principle

In the formation process, the lithium ion at the electrode/electrolyte liquid phase interface reacts irreversibly with solvent molecules in the electrolyte to form SEI film. On the one hand, this film consumes the limited lithium ions in the battery, and more lithium containing anode materials are needed to compensate for the lithium consumption during the initial charging process. On the other hand, the resistance of the electrode/electrolyte interface is also increased, resulting in a certain voltage lag.

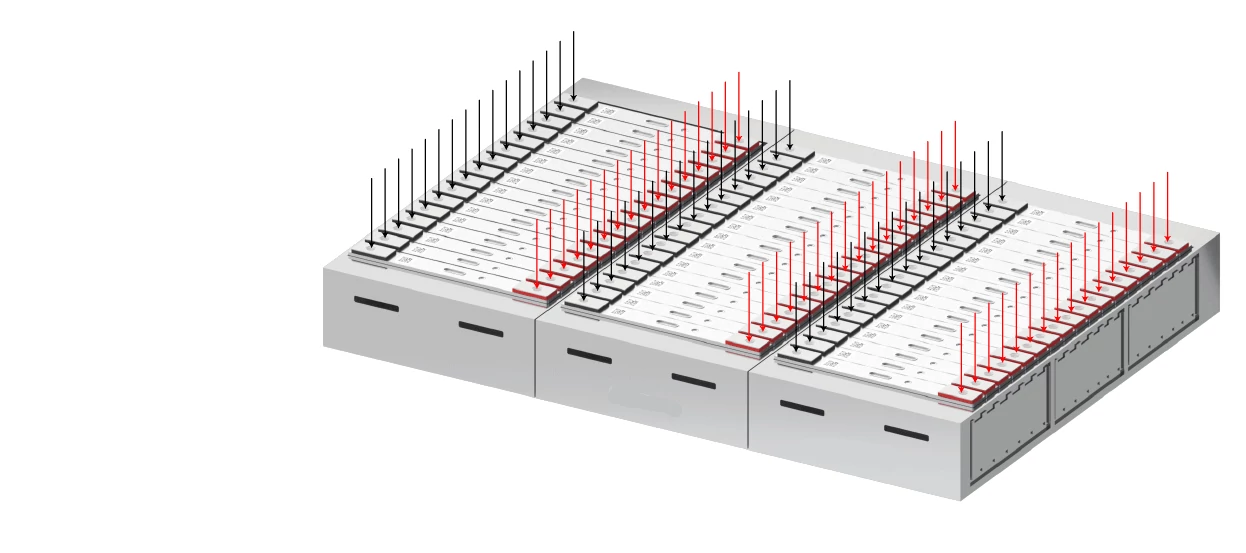

Type of formation process

The formation process can be divided into high temperature formation, low temperature formation, high current formation, low current formation, open formation, closed formation and negative pressure formation, etc. These processes are different according to the temperature, current, injection port and other conditions.

Effect of formation conditions on battery performance

Formation temperature, external pressure and other factors will affect the SEI film formation and battery performance. For example, some components of the SEI film may decompose at high temperatures, causing the SEI film to rupture, which will further consume lithium to generate a new SEI film.

The formation process setup case

The setting of the formation process has a significant effect on the battery performance. For example, the use of limited volume formation can improve the consistency of battery formation. The formation process usually includes pre-treatment, charge and discharge, cyclic voltammetry measurement, termination formation and post-treatment.

CONCLUSION

Through the above detailed formation process introduction, it can be seen that formation is an indispensable part of the production of lithium batteries, and its impact on the performance of lithium batteries is crucial. By precisely controlling the formation conditions, a uniform and dense SEI film can be formed, thereby improving the cycle life and safety of lithium batteries.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.