EPS inverter inverter circuit details – switching components Fire Emergency...

EPS shell material - metal material

In modern society, fire safety is an important link to ensure public safety. Emergency Power Supply (EPS), as an important part of the fire protection system, plays a vital role. EPS can provide reliable power protection for fire fighting equipment in case of power failure or emergency. In this type of system, the choice of housing material has an important impact on its performance, durability and safety. Metal material is an ideal choice for EPS shell material because of its excellent properties. This article will introduce metal materials in detail.

main content

Steel shell

Steel is one of the commonly used metal materials for battery casings and is known for its high strength and good plasticity. The steel shell can effectively protect the internal structure of the battery and resist external pressure and impact. In cylindrical lithium batteries, steel is widely used as a shell material because of its physical stability. In order to prevent the oxidation of the battery positive active material to the steel shell, nickel plating is usually used to protect the iron matrix of the steel shell.

Stainless steel case

Stainless steel is also a common material for battery casings, which has good corrosion resistance and can extend the service life of batteries. Stainless steel housings are usually made of stainless steel or aluminum and provide excellent protection against physical damage. In addition, the metal housing can effectively dissipate the heat generated during battery operation, contributing to overall safety and performance. In some cases, stainless steel housings require surface treatment to improve their corrosion resistance, such as nickel plating.

Nickel-plated steel housing

Nickel-plated steel is another metal material commonly used in battery casings. Nickel plating treatment can improve the corrosion resistance of the steel shell and prevent the oxidation of the active material of the positive electrode of the battery. The surface iron content of the nickel plating layer is controlled to ≤15% to promote the welding connection between the coating and the dissimilar metal and strengthen the welding bonding force. The thickness of the nickel plating layer is usually 1 to 5μm, preferably 2 to 4μm to include the thickness of the Fe-Ni diffusion alloy layer. In addition, the surface roughness of nickel-plated steel is controlled at 0.5 ~ 2.0μm, preferably 1 ~ 1.5μm, in order to increase the welding area between the coating surface and the dissimilar metal, and increase the welding bonding force.

CONCLUSION

In summary, the metal material housing of EPS battery cells, including steel, stainless steel and nickel-plated steel, all play an important role in battery manufacturing with their respective advantages. The steel shell protects the battery with its high strength and plasticity, the stainless steel shell extends the battery life with its corrosion resistance, and the nickel-plated steel shell improves corrosion resistance and weldability through nickel-plated treatment. The selection and application of these materials have their own advantages and limitations according to different application scenarios and performance requirements.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

Battery cell – lithium-ion battery

Battery cell – lithium-ion battery Lithium-ion batteries are one of...

EPS inverter DC input part analysis: DC-DC converter

EPS inverter DC input part analysis: DC-DC converter The DC-DC...

Control system analysis of EPS inverters – Microcontroller (MCU) or Digital Signal Processor (DSP)

Control system analysis of EPS inverters – Microcontroller (MCU) or...

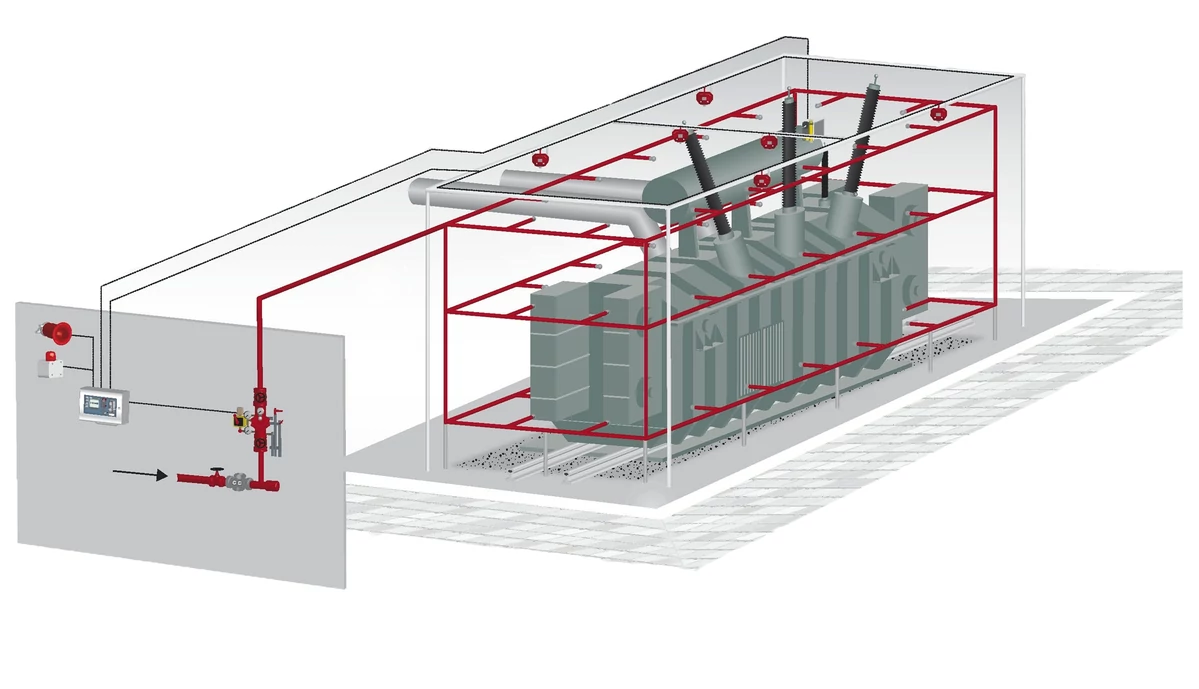

Detailed explanation of the transformer system of EPS inverter

Detailed explanation of the transformer system of EPS inverter In...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.