Safety valve and pressure release device of EPS battery unit...

EPS battery unit seal

In battery technology, seals are key components to ensure battery performance and safety. EPS (Encapsulated Power System) battery unit sealing materials need to have multiple characteristics such as temperature resistance, corrosion resistance, and good elasticity to cope with the complex chemical environment inside the battery. The following details the properties of six key sealing materials and their applications in EPS cell cells.

main content

Fluororubber (FKM)

Fluororubber (FKM) is a high-performance material that is widely used in demanding sealing applications. Its main features include:

High temperature resistance: Fluorine rubber can work stably in the temperature range of -20 ° C to +250 ° C to meet the needs of sealing in high temperature environments.

Chemical stability: Strong resistance to a variety of chemicals, including acids, alkalis, solvents, etc., helps prevent electrolyte leakage.

Excellent physical properties: with good elasticity and compressive deformation resistance, can maintain a stable sealing effect.

Aging resistance: It can resist the effects of oxidation and ozone to ensure the stable performance of the material in long-term use.

Overall, fluororubber is an ideal choice for high-end battery seals because of its superior performance.

Silicone rubber (VMQ)

Silicone rubber (VMQ) is a siloxane-based synthetic material suitable for battery sealing with the following advantages:

Strong temperature resistance: wide operating temperature range, from -60℃ to +230℃ can work stably, suitable for various climatic conditions.

Excellent electrical insulation: it can effectively prevent the risk of short circuit inside the battery and improve the safety of use.

Excellent flexibility: Good elasticity allows it to adapt to dynamic changes in the battery structure, such as thermal expansion and contraction.

UV and ozone resistance: UV and ozone resistance allows it to maintain its physical properties for a long time in harsh environments.

As a result, silicone rubber provides increased safety and reliability in the battery package.

EPDM (ethylene propylene diene monomer rubber)

EPDM is an environmentally friendly synthetic rubber suitable for battery sealing for the following reasons:

Heat resistance: Capable of operating at temperatures up to 130 ° C, suitable for the environmental requirements of most batteries.

Weather resistance: Good resistance to climate aging makes it stable in outdoor or extreme weather.

Ozone resistance: strong resistance to ozone, effectively reducing the aging rate during use.

Excellent elasticity: EPDM's elasticity and tear resistance make the seal more reliable.

Because of its excellent cost performance, EPDM has become a common sealing material for a variety of batteries.

Polyurethane (PU)

Polyurethane (PU), as a material for battery seals, has the following characteristics:

Strong wear resistance: The wear resistance of PU makes it excellent in long-term use and can resist mechanical friction.

Oil resistance: Good resistance to the oil and chemical media used by the battery to ensure the sealing effect.

Weather resistance: strong adaptability, excellent resistance to environmental changes, and can keep sealed under different climatic conditions.

Excellent elasticity: The flexibility of PU enhances the durability of seals against thermal expansion and other dynamic loads.

As a result, polyurethane seals perform well in applications where wear and oil resistance are required.

Polymer composite

Polymer composites offer superior physical and chemical properties by combining a variety of polymers and reinforcers:

Overall performance: The hardness, strength and flexibility of the seal can be customized by adjusting the filler and base material.

Versatility: Composites can be designed to be electrically conductive, flame retardant, UV resistant and antibacterial to meet the needs of different applications.

Lightweight design: Due to the lightweight characteristics of the composite material, it is expected to further improve the energy density and efficiency of the battery.

Polymer composites are increasingly used in battery seals because of their flexible and customizable properties.

Nitrile butadiene rubber (NBR)

Nitrile butadiene rubber (NBR) is a commonly used sealing material with certain advantages and disadvantages:

Oil resistance: Excellent resistance to oil and fuel, suitable for battery environments containing oil.

Sealing performance: Good sealing capability ensures that liquid leakage is prevented, suitable for battery applications.

Wear resistance: strong resistance to wear, excellent performance, suitable for long-term use.

Temperature limitation: It usually does not perform as well as FKM and VMQ in high temperature environments, and its aging speed is faster, limiting its application range.

Despite some shortcomings in high temperature performance, NBR is still a cost-effective sealing material that works effectively under a variety of conditions.

CONCLUSION

The selection of sealing material of EPS battery cell is very important. Fluorine rubber, silicone rubber, EPDM, polyurethane, polymer composite and nitrile rubber have advantages and disadvantages, suitable for different types of battery needs. With the development of battery technology, the requirements for sealing materials will be more stringent, and the future will continue to promote the development and application of new materials to improve the performance and reliability of battery sealing.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

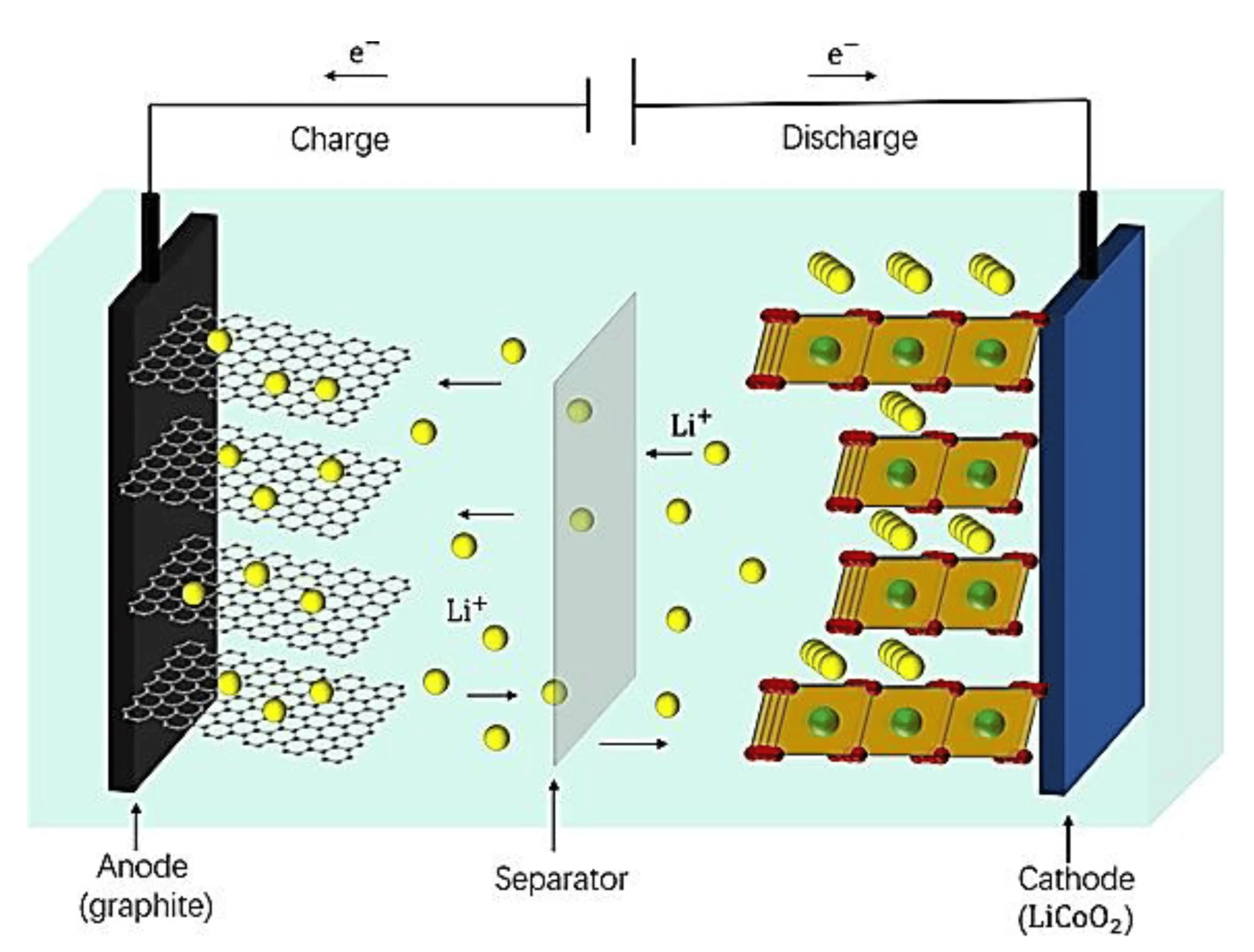

What is the practical application effect of polymer electrolyte in batteries?

What is the practical application effect of polymer electrolyte in...

EPS inverter protection circuit analysis – temperature sensor

EPS inverter protection circuit analysis – temperature sensor Emergency power...

Materials for safety valves and pressure relief devices – superalloy springs

Materials for safety valves and pressure relief devices – superalloy...

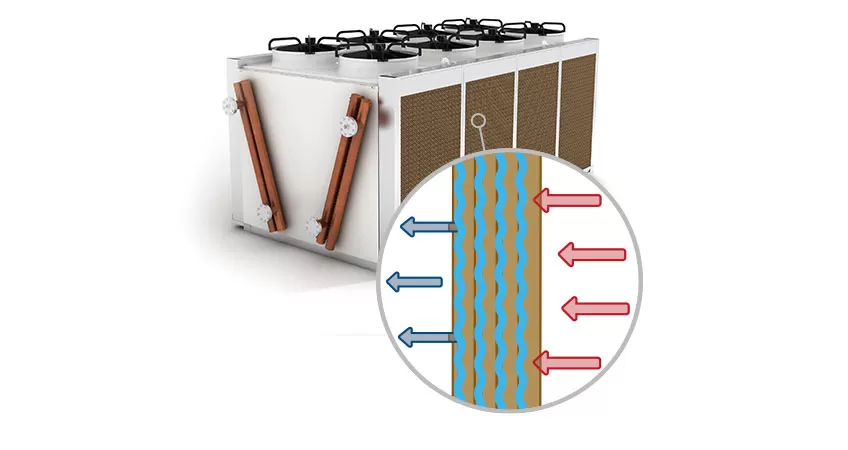

Cooling systems for EPS inverters: key components and working principles

Cooling systems for EPS inverters: key components and working principles...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.