EPS inverter inverter circuit details – switching components Fire Emergency...

EPS battery unit

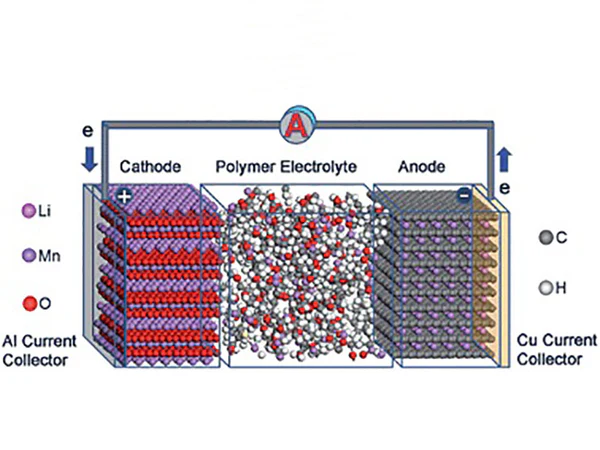

In the construction of battery cells, the selection and design of each component plays a crucial role in the performance, efficiency and safety of the battery. The main components of the EPS (Emergency Power System) battery cell are described in detail here, including positive electrode material, negative electrode material, electrolyte, isolation film, battery housing, electrode fluid collector and seals.

main content

The cathode material of the battery is an important part of the lithium-ion battery, which is mainly responsible for providing electrons during charging and discharging. Commonly used cathode materials include nickel cobalt manganese oxide (NCM), nickel cobalt aluminum oxide (NCA) and so on. These materials in the battery charging and discharging process, lithium ions from the positive material, through the electrolyte embedded in the corresponding negative material, while electrons from the positive electrode flow through the external circuit to the negative electrode.

Negative electrode material is one of the important raw materials of lithium-ion battery, which has great influence on the energy density, cycle performance, charge and discharge ratio and low temperature discharge performance of lithium-ion battery. Commonly used anode materials are graphite or silicon-based materials, which store lithium ions when charged and release them when discharged. Because of the relatively superior cycle performance and safety performance, the market share of artificial graphite anode has increased year by year and occupies a dominant position for a long time.

An electrolyte is a chemical used to transfer lithium ions, usually a solution of lithium salts (such as lithium carbonate) or a polymer electrolyte . The electrolyte acts as an ion transport in the battery, allowing lithium ions to move between the positive and negative electrodes, completing the charge-discharge cycle.

The isolation membrane is a porous material used to separate the positive and negative electrodes of a battery, preventing short circuits and allowing lithium ions to pass through freely. The main function of the diaphragm is to separate the positive and negative active substances of the battery to prevent short-circuit contact between the two poles; At the same time, the micropores in the film allow the current-carrying lithium ions in the electrolyte to pass through, forming a charge and discharge loop.

The battery shell is the external structure of the battery, which protects the cell inside the battery from external physical damage. The shell material can be steel shell, aluminum shell or aluminum-plastic film, which have different physical characteristics and manufacturing processes. The battery shell needs to have sufficient structural strength to resist the expansion force of the battery cell, and the reaction force is added to the battery cell to play a fixed role.

The electrode collector is the part of the battery that collects and transmits current. The positive collector is usually made of aluminum, while the negative collector is made of copper. The shape and surface treatment of the fluid collector have important effects on the electrochemical performance of the battery.

The seal is used to seal the battery unit and ensure the air tightness and liquid tightness of the battery. They are usually used in conjunction with the cover assembly to ensure that the cell inside the battery is isolated from the external environment, preventing moisture and air from entering the battery.

CONCLUSION

Each component in the EPS battery unit works with each other to form the core functional system of the battery. Anode material, anode material, electrolyte, isolation film, battery housing, electrode collector fluid and seal together determine the performance, safety and suitability of the battery. When selecting a battery cell, the materials and design of these aspects should be considered comprehensively to meet the specific application needs.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

The electrode of EPS battery cell collects fluid

The electrode of EPS battery cell collects fluid The electrode...

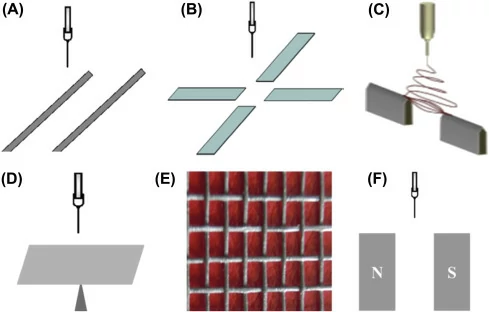

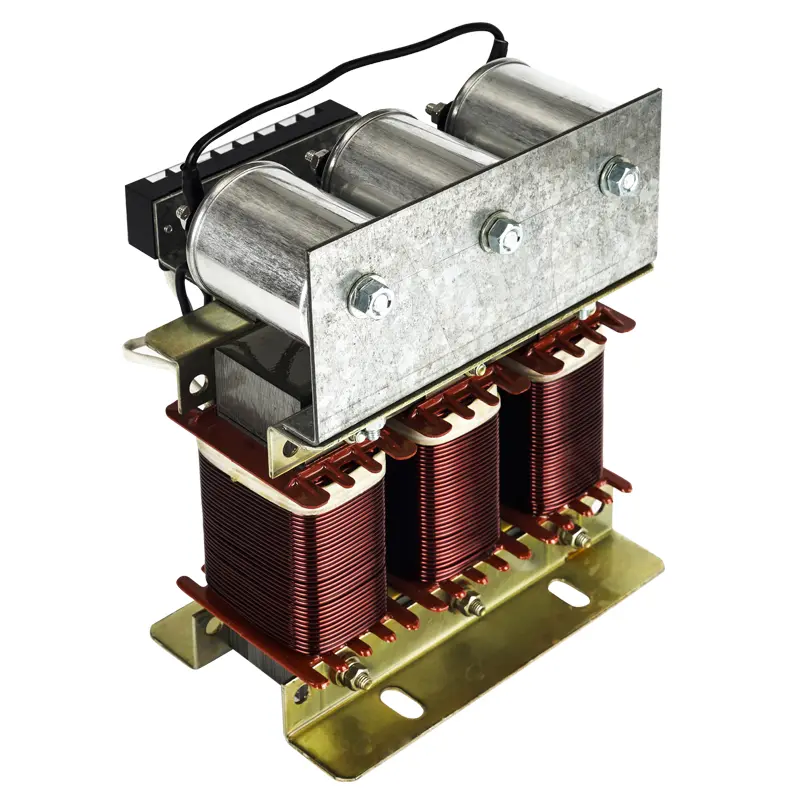

EPS inverter output filter analysis

EPS inverter output filter analysis In the emergency power supply...

This section describes the wireless interface of the EPS

This section describes the wireless interface of the EPS In...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.