A method for measuring the electrical conductivity of a battery...

Discharge cutoff voltage

The discharge cutoff voltage is an important parameter in modern electronic devices and battery management systems. It refers to the voltage value at which the battery stops discharging operation when the voltage drops to a specific minimum level during discharging. The setting and management of the discharge cutoff voltage is closely related to the performance, safety, lifetime and application efficiency of the battery. This paper will deeply discuss the definition, importance, influencing factors of discharge cutoff voltage and how to set and manage this parameter reasonably.

definition

Cut-off Voltage for Discharge refers to the voltage value that stops the discharge when the battery voltage reaches a predetermined minimum during battery discharge. Usually, this parameter is clearly marked in the battery design and application instructions to ensure that the battery works under safe and effective operating conditions. When the voltage of the battery drops to this value, continuing to discharge may cause damage to the battery and even cause safety hazards.

The importance of charge Cut-off Voltage

The discharge cutoff voltage is critical to the performance and lifetime of a battery, and the following are its main importance:

The discharge cutoff voltage is critical to the performance and lifetime of a battery, and the following are its main importance:

Extend the service life: reasonable discharge cut-off voltage can effectively extend the service life of the battery, to avoid the shortening of cycle life caused by deep discharge.

Improve safety: setting the appropriate discharge cutoff voltage can significantly reduce the risk of serious safety accidents such as explosion and leakage caused by battery overdischarge, and ensure the safety of users.

Ensure device performance: In applications such as electronic devices or power tools, a suitable discharge cutoff voltage can ensure that the device provides good performance while avoiding the impact of low battery power on service life or performance.

Factors affecting discharge cutoff voltage

The setting of discharge cutoff voltage is affected by many factors, mainly including:

Battery type: Different types of batteries (such as lead-acid batteries, lithium-ion batteries, nickel-metal hydride batteries, etc.) have different chemical and voltage characteristics, so their discharge cutoff voltages are different. For example, lithium-ion batteries typically have a discharge cutoff voltage between 2.5V and 3.0V, while lead-acid batteries typically have a discharge cutoff voltage between 10.5V and 11.8V.

Environmental conditions: Environmental factors such as temperature and humidity also have an impact on the performance of the battery, and extreme environmental conditions may lead to abnormal battery performance at the standard discharge cutoff voltage.

Discharge rate: A discharge rate that is too fast may cause the battery to generate a lot of internal heat, reducing the available voltage. Therefore, devices operating at high discharge rates, may require higher cutoff voltage Settings.

Reasonable setting and management

It is very important for the safety and performance of battery to set the discharge cutoff voltage reasonably. Here are some best practice recommendations:

Follow manufacturer's recommendations: Always follow the battery manufacturer's recommendations and standards to ensure that the discharge cutoff voltage is set to meet the requirements of the specific battery type.

Use of Battery Management System (BMS) : In high-performance battery systems, the battery management system can monitor the battery status in real time and automatically adjust the discharge cutoff voltage to ensure that the battery works within a safe range.

Regular inspection: Regularly evaluate the health status of the battery, and timely find and adjust the unreasonable discharge cutoff voltage setting through the inspection and maintenance in practice.

User TRAINING: FOR users of battery products, provide necessary training and guidance to make them understand the importance of discharge cut-off voltage and operational precautions.

Conclusion

The discharge cutoff voltage is an important determinant of battery safety, performance and lifetime. Reasonable setting and management of this parameter can effectively protect the battery, prolong the service life, improve safety, and ensure the reliable operation of the equipment. With the continuous progress of battery technology, especially the wide application in electric vehicles, renewable energy storage, and various electronic devices, a deep understanding of the importance of discharge cutoff voltage will provide us with better support in future battery management and applications. Through scientific management and reasonable setup, we can not only improve the performance and safety of batteries, but also advance the goal of sustainable development.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

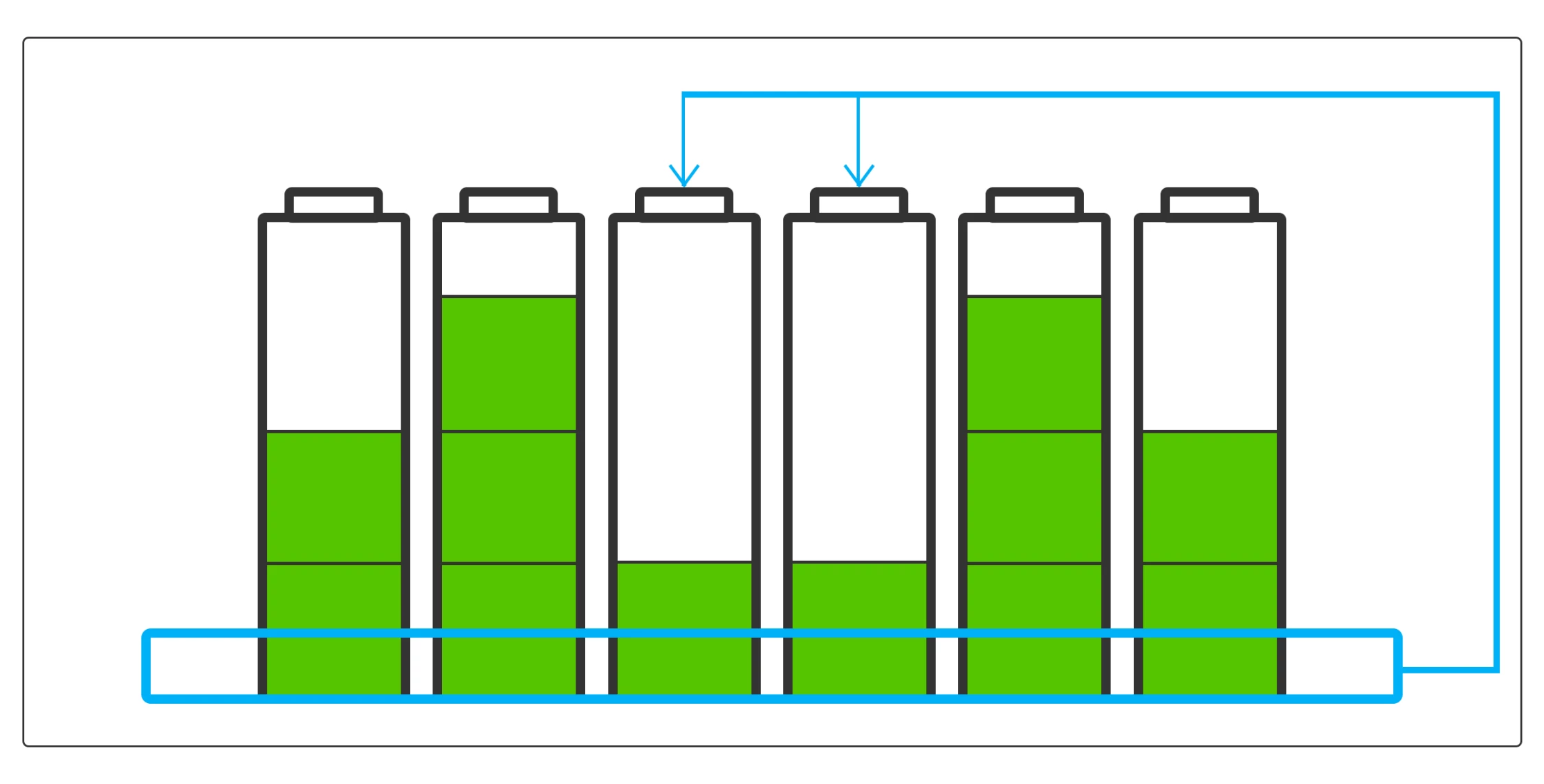

Passive Balanced Battery Management System (BMS)

Passive Balanced Battery Management System (BMS) With the rapid development...

The function of negative electrode of lithium iron phosphate battery

the function of negative electrode of lithium iron phosphate battery...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.