User guide The use guide for tower backup energy storage...

Diaphragm

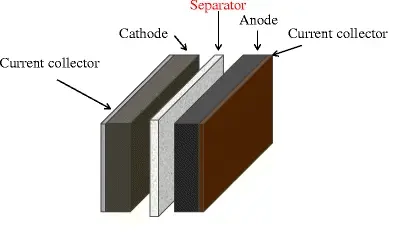

The diaphragm is an important part of the tower backup energy storage battery, which plays the role of separating the positive and negative electrodes, preventing short circuit and ensuring efficient transmission of lithium ions. The performance of the diaphragm directly affects the safety, conductivity, cycle life and temperature stability of the battery.

Diaphragm

The diaphragm is an indispensable part of the tower backup energy storage battery, and its main role is to prevent short circuit of the positive and negative electrodes and provide the transmission channel of lithium ions. High-quality membranes not only need to have efficient ionic conductivity, but also have good electrical insulation, thermal stability and mechanical strength to ensure the safety and stability of the battery during the charge and discharge process. Selecting the right diaphragm material and optimizing its performance are key to improving battery safety, extending service life and improving the overall reliability of the system.

Detailed information

Main material

Polyethylene (PE)

Features: Polyethylene is a common diaphragm material with good electrical insulation and mechanical strength.

Advantages: Polyethylene diaphragms have a low cost and are stable and reliable over conventional temperature ranges.

Application: Widely used in most lithium batteries, especially energy storage systems with high requirements for safety and reliability.

Polypropylene (PP)

Features: Polypropylene diaphragm has lower porosity and better mechanical strength.

Advantages: Good high temperature resistance, suitable for use at higher operating temperatures.

Application: Often used with polyethylene diaphragm to optimize the safety and stability of the battery.

Polymer composite

Features: It is composed of polyethylene or polypropylene and other high-performance materials (such as ceramics, glass fiber).

Advantages: Composite diaphragms combine the benefits of a variety of materials, such as better thermal stability and pressure resistance, to improve battery safety, especially at high temperatures.

Applications: Used in high-end lithium batteries, ultra-long life batteries and energy storage systems with high safety requirements.

Performance requirement

Ionic conductivity

The porosity and pore size distribution of the diaphragm affect the conduction efficiency of lithium ions, and the structure of too dense or too sparse will affect the smooth flow of ions. The ideal diaphragm material should have high ion conductivity to improve the charging and discharging efficiency of the battery.

Electrical insulation

The diaphragm needs to have good electrical insulation to prevent short circuit caused by direct contact between the positive and negative electrodes.

Thermal stability

The diaphragm must have good high temperature resistance to cope with the high temperatures that may be generated when the battery is running at high loads, to avoid melting or damage during overheating. The thermal stability of the diaphragm determines the safety of the battery in extreme environments.

Mechanical strength

The diaphragm should have sufficient mechanical strength to prevent rupture or damage due to expansion or contraction during charging and discharging.

Chemical stability

The diaphragm must have good chemical stability to the electrolyte, lithium salt and other battery components to avoid side reactions with the electrolyte.

Function and effect

Prevent short circuit

The most basic function of the diaphragm is to prevent short circuit caused by direct contact between the positive and negative electrodes. A good diaphragm can keep the electrode effectively isolated during the battery charging and discharging process to avoid safety accidents.

Lithium ion transport channel

The diaphragm provides a channel for lithium ions to migrate between the positive and negative electrodes, ensuring that the battery can successfully complete the charge and discharge process. The porosity and thickness of the diaphragm affect the migration efficiency of lithium ions, which in turn affects the overall performance of the battery.

Improve battery safety

In the case of high temperature or external pressure changes, the diaphragm can prevent internal delamination or contact of the battery, prevent internal short circuit, and effectively avoid safety hazards such as fire or explosion. Some advanced diaphragm materials also have melting function, which automatically melts when the temperature is too high, cutting off the current and protecting the battery.

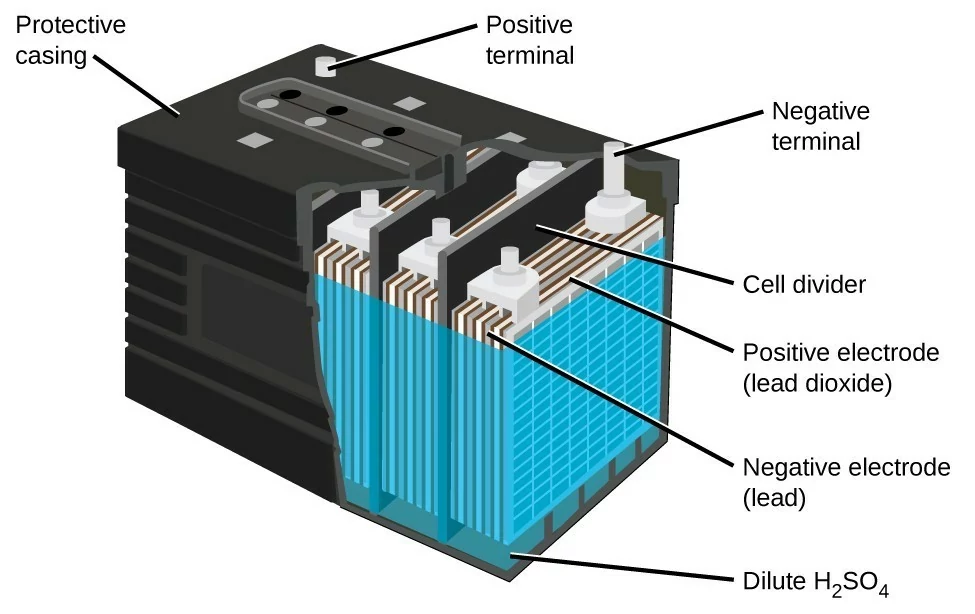

TOWER BACKUP BATTERY

With its integrated structural design, intelligent BMS monitoring, and standardized cabinet installation, ESS 48V series lithium iron phosphate batteries can provide reliable backup power for access network equipment, remote exchange, mobile communication, transportation equipment, emergency power and other systems.

Extended reading

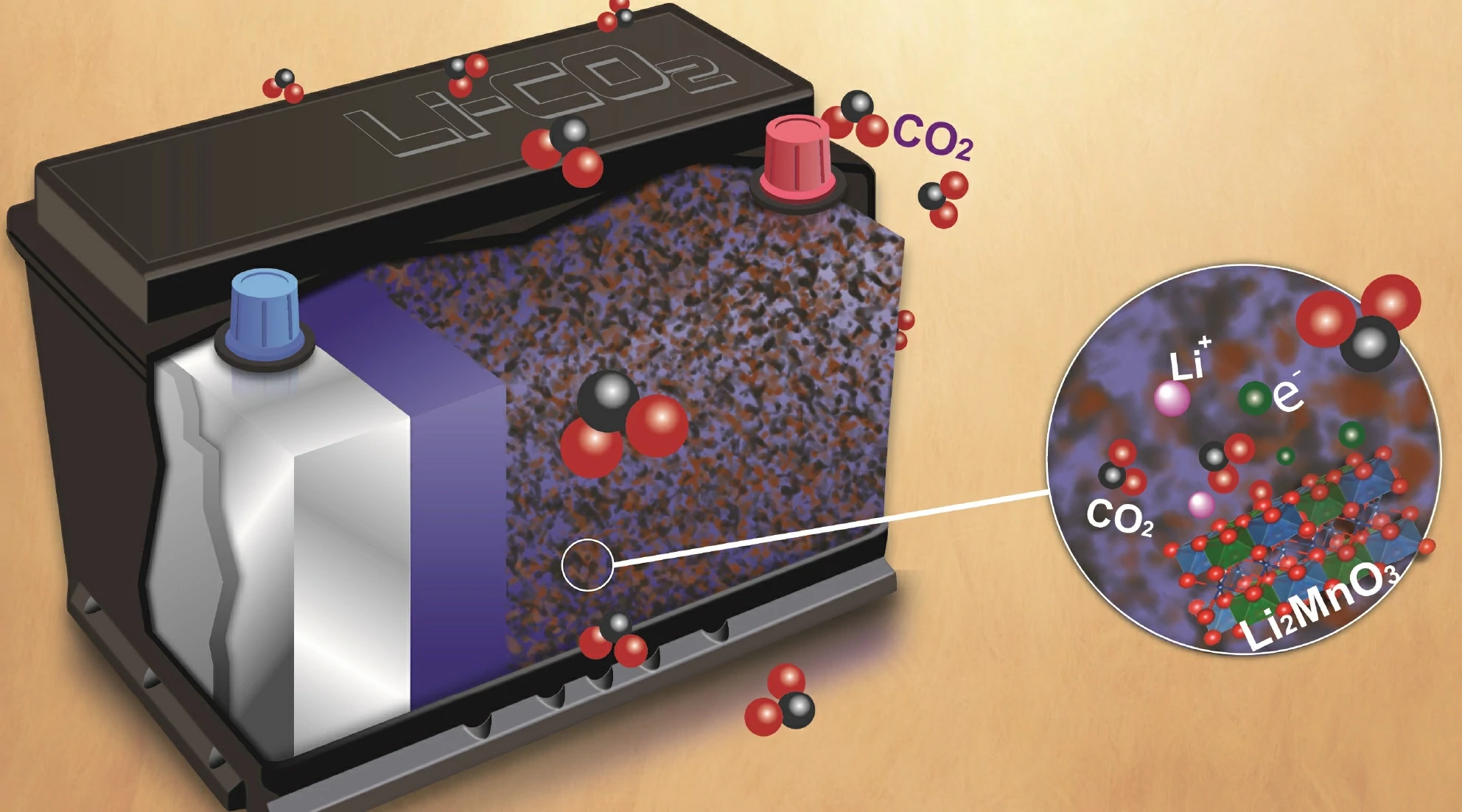

Working principle and process flow

Working principle and process flow The working principle of the...

Product update direction and recycling

Product update direction and recycling The product update direction of...

Application scenario

Application scenario The application scenario of tower backup energy storage...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.