Product testing Product testing is a key link to ensure...

Lithium-ion battery separator

A microporous film, usually made of polyethylene (PE) or polypropylene (PP), prevents short circuits in the positive and negative electrodes while allowing the flow of lithium ions.

Lithium-ion battery separator

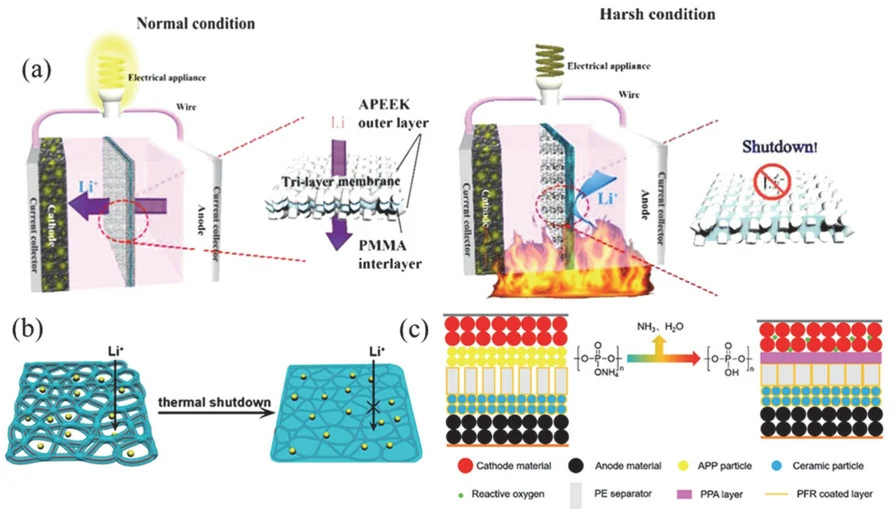

The diaphragm is a very critical component in lithium batteries, usually made of materials such as polymers or ceramics, and acts as a separation between the positive and negative electrodes of the battery. The diaphragm not only prevents the direct contact of the positive and negative electrodes from short circuit, but also allows lithium ions to migrate freely during charge and discharge. The quality and performance of the diaphragm have a profound impact on the safety, performance and life of the battery.

Information about the Lithium-ion battery separator

Function of diaphragm

Prevent short circuit: The most basic function of the diaphragm is to isolate the positive and negative electrodes of the battery, prevent them from direct contact, and avoid the occurrence of short circuit. It ensures that electrons from the positive and negative electrodes do not come into direct contact by providing sufficient physical space and electrochemical stability.

The conduction of lithium ions: The diaphragm is not only a physical isolation layer, but also allows lithium ions to pass through during the charge and discharge process to maintain the normal operation of the battery. Therefore, the diaphragm needs to have good ionic conductivity.

Thermal stability: The thermal stability of the diaphragm is critical when the battery is overheated, short-circuited or overcharged. The high-quality diaphragm is able to withstand high temperatures and prevent thermal runaway inside the battery, thus enhancing the safety of the battery.

Material of diaphragm

Polyethylene (PE) and polypropylene (PP) : These two materials are the most commonly used diaphragm materials today. They have good chemical stability, high electrical conductivity and low cost. The pore structure of PE and PP materials facilitates the migration of lithium ions and provides the necessary physical strength.

Ceramic diaphragm: Ceramic diaphragm is the addition of ceramic coating on the traditional polymer-based diaphragm, the purpose is to improve the thermal stability of the diaphragm, to prevent the battery in high temperature environment short circuit or thermal runaway. Ceramic materials usually have good thermal conductivity and thermal stability, so they can improve the safety of the battery.

Composite diaphragms: To combine the advantages of polymers and ceramics, composite diaphragms have been developed in recent years. These diaphragm materials combine the flexibility of polymers with the high thermal stability of ceramics and are suitable for high-performance lithium batteries.

Performance requirements for diaphragms.

Ionic conductivity: The porosity and pore size of the membrane have an important effect on the migration rate of lithium ions. An ideal diaphragm should have high ionic conductivity, but not be too loose to cause a short circuit.

Mechanical strength: The diaphragm needs to have sufficient mechanical strength to prevent damage caused by expansion or contraction during the battery charging and discharging process, resulting in battery failure.

Thermal stability and high temperature resistance: the diaphragm should be stable at high temperatures to prevent overheating or internal short circuit. The ideal diaphragm can maintain normal function in a high temperature environment above 130 ° C.

Chemical stability: The diaphragm must be chemically stable to the electrolyte and should not react with the components in the electrolyte to ensure the long life and safety of the battery.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.