The shell material of the battery shell The battery case...

Cycle life test of single cell battery

With the development of renewable energy and electric vehicle technology, single cell batteries are more and more widely used in various fields. Cycle life test is an important part of evaluating the performance and reliability of a battery, which can effectively determine the ability of a battery to maintain its performance during multiple charges and discharges. This article will introduce the operation process of single battery cycle life test, the required instrument and the matters needing attention.

the purpose of cycle life test

Performance evaluation: The performance stability and persistence of the battery are evaluated by simulating the charging and discharging process under actual use conditions.

Capacity retention: determine the capacity change of the battery after multiple charging and discharging, and understand the decay rate of the battery for subsequent application and optimization design.

Safety analysis: identify the security risks in the long-term use of the battery to ensure safety in the whole life cycle.

Compliance with standards: ensure that the cycle life of the battery conforms to industry standards and provides a guarantee for market access.

the basic principle of cycle life test

Cycle life testing is usually performed by charging and discharging the battery several times, and by periodically monitoring its capacity, internal resistance and other performance indicators to observe whether the battery shows significant performance attenuation during this process. The test results can provide an important basis for the design and application of batteries.

Operation process of cycle life test

Preparation Phase

Ensure that the testing environment meets the relevant safety standards, check that the required instruments and equipment are complete and functioning properly.

Select the charge and discharge tester

Selecting the appropriate battery charge and discharge tester can achieve accurate current and voltage control and data recording.

Battery preparation

The single battery to be tested is preprocessed, such as first charging and discharging, to achieve the specified cycle test conditions.

Set the test parameters

Parameters such as charge and discharge current, charge cutoff voltage, discharge cutoff voltage, and cycle times are set according to the battery type and test standard.

Start the tests

Start the charge and discharge tester and start the set cycle test. During the whole testing process, various performance parameters of the battery, such as voltage, capacity, and internal resistance, were recorded periodically.

Monitor and record data

During the test, the state of the battery is continuously monitored to ensure the integrity and accuracy of the data.

End the test

When the preset number of cycles is reached, the test is stopped and the final electrical performance measurement and appearance inspection of the battery are carried out.

Data analysis and report

Collect and analyze the test data, evaluate the capacity retention rate and cycle efficiency of the battery, write the test report, and determine the cycle life performance of the battery.

Required instruments and equipment

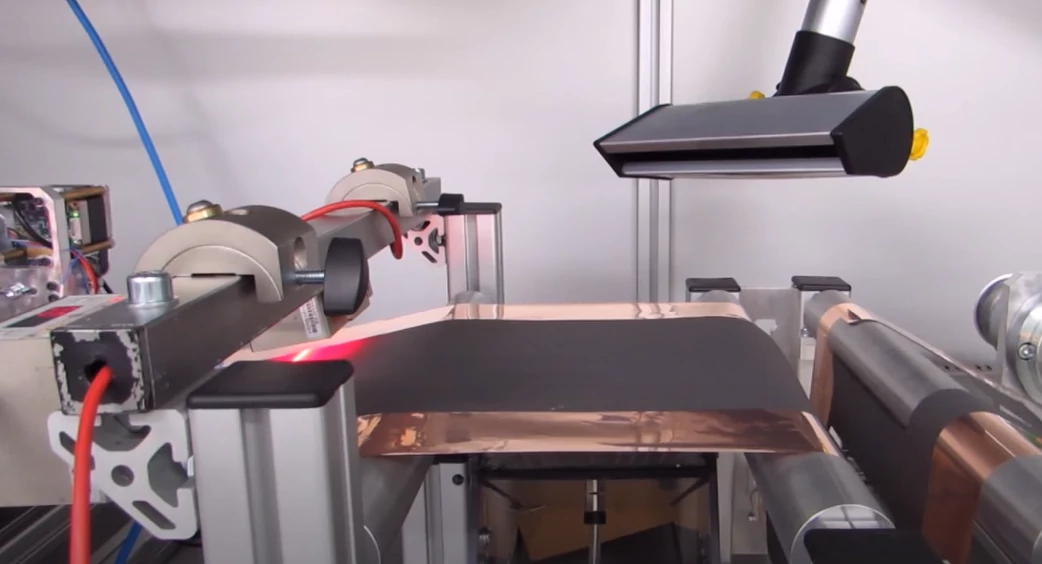

Charge and discharge tester

Key equipment, used to control the charging and discharging process of the battery, can accurately control the current and voltage.

Data logger

It is used to record the voltage, capacity, internal resistance and other performance data of the battery during the test in real time to ensure the accuracy of the results.

Environmental monitoring equipment

It is used to monitor and control the temperature and humidity of the test environment to ensure the consistency of the test conditions.

Battery aging test box

It is suitable for long-term stability testing of batteries under specific environmental conditions.

Thermometer and hygrometer

It is used to monitor the temperature and humidity of the test environment to ensure the stability of the parameters in the test process.

Precautions

Security:

Pay close attention to the state of the battery during the test and deal with any abnormal phenomenon in time to ensure the safety of personnel and equipment.

Environmental Control:

The test environment should be kept constant to avoid the impact of drastic fluctuations in temperature and humidity on the battery performance.

Instrument calibration:

Before testing, ensure that the charge and discharge tester and other equipment are calibrated to ensure the accuracy of the data.

Test record:

Maintain detailed test records to ensure that the data of each stage is clear and legible for subsequent analysis and comparison.

Results analysis:

When analyzing the results, we pay attention to the trend and reason of capacity attenuation, and conduct comparative tests if necessary to verify the conclusions.

Conclusion

Cycle life testing is a key step to evaluate the performance and safety of single cell batteries in long-term use. Through the standardized test process and high-precision instruments and equipment, it can not only effectively identify the potential problems of the battery in multiple charging and discharging, but also provide a theoretical basis for the improvement and application of the battery. With the continuous progress of science and technology, strengthening the test and analysis of battery cycle life will help to improve the performance and market competitiveness of batteries.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Study on mechanical protection material of positive cap

Study on mechanical protection material of positive cap In modern...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.