Dry and store Dry storage in the production process of...

Crush

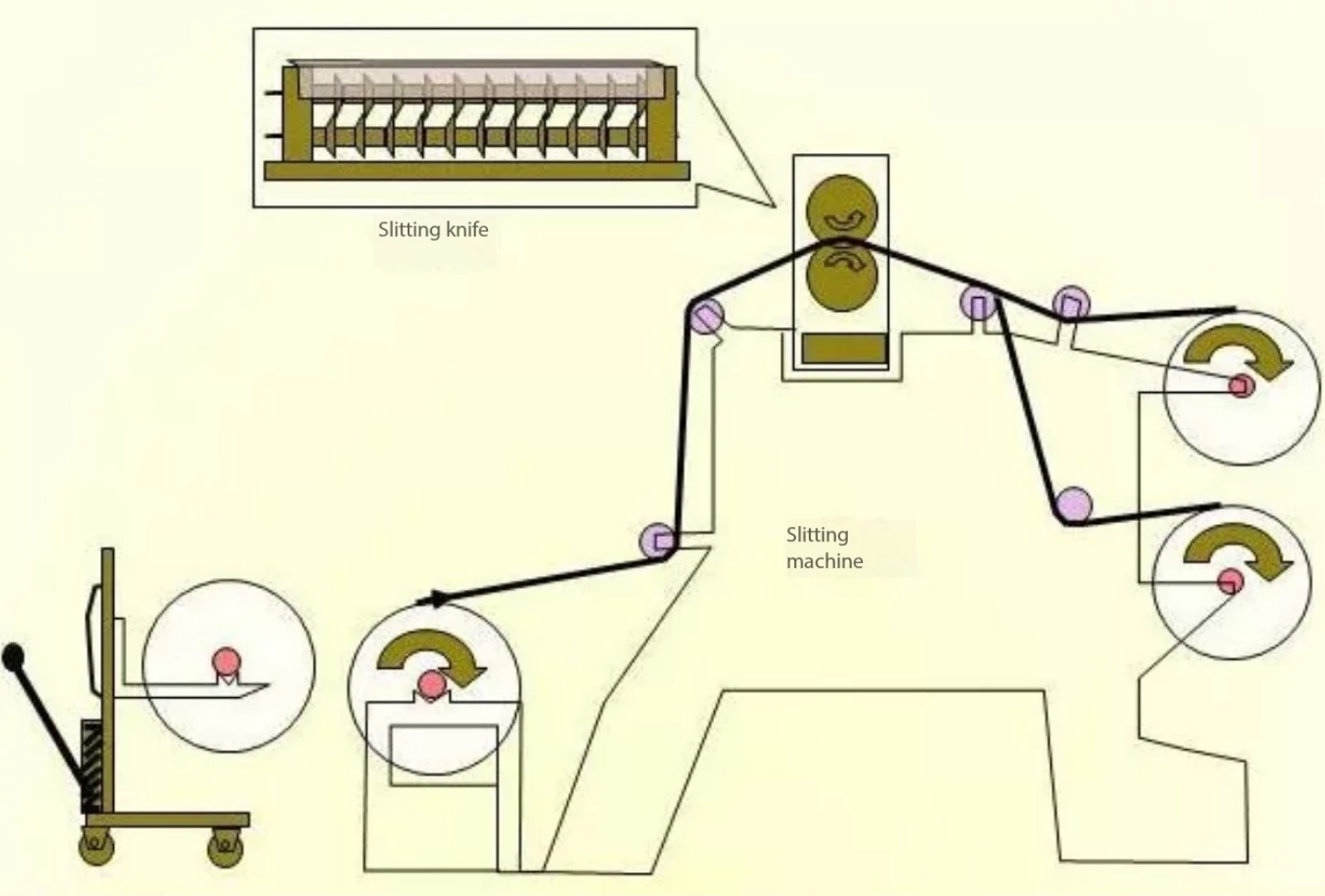

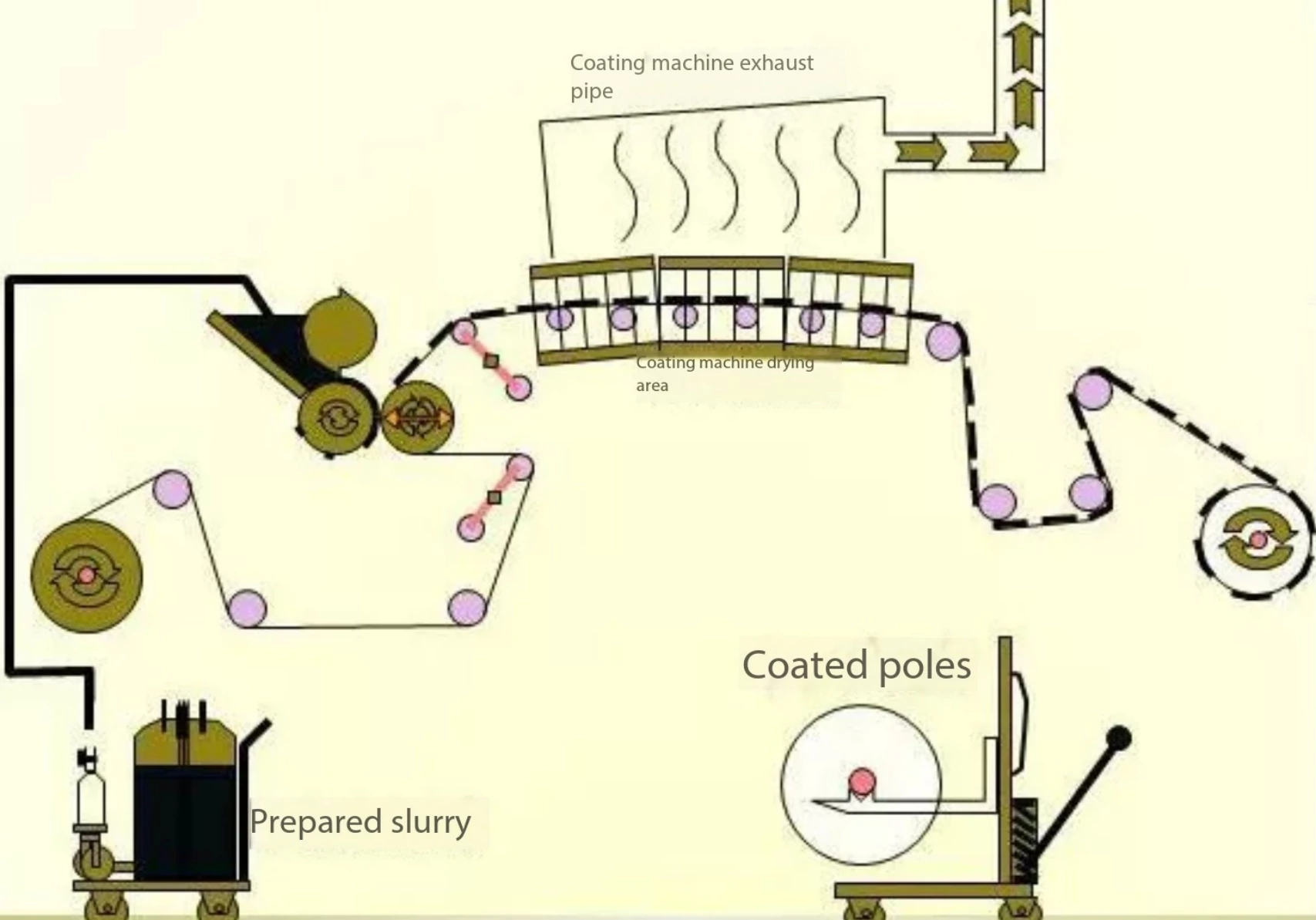

The rolling (rolling) process in the production of lithium battery is a very important part of the battery manufacturing process, and its main purpose is to compact the coated electrode sheet to enhance the bonding strength of the active substance and the fluid collector foil, and improve the performance of the battery. The following is a detailed introduction to the rolling process:

Crushing purpose

Improve the density of the electrode sheet: Through rolling, the active substance in the electrode sheet and other additives can be tightly combined to improve the density of the electrode sheet, which is conducive to improving the energy density and capacity of the battery.

Uniform electrode thickness: Rolling can make the thickness of the electrode more uniform, to avoid the instability of battery performance caused by uneven thickness.

Improve the mechanical strength of the electrode sheet: Rolling increases the mechanical strength of the electrode sheet and reduces the fracture and deformation during preparation, assembly and use.

Improve the conductivity of the electrode sheet: the conductive agent in the electrode sheet can be evenly distributed by rolling, and the conductivity of the electrode sheet can be improved, which is conducive to improving the charge and discharge performance of the battery.

Rolling process parameter control

In the production of lithium batteries, the following aspects should be controlled when rolling is the positive and negative parts of the battery:

Roll temperature: Controlling the roll temperature can affect the combination of the battery and the electrolyte layer and the diaphragm, and it is generally necessary to roll within a certain temperature range.

Roll pressure: The appropriate roll pressure can ensure that the battery and the electrolyte layer, the diaphragm is tightly combined, but too much pressure may cause the battery deformation or damage.

Pole-sheet characteristics after rolling

Smooth and flat surface of the pole plate: roller press ensures smooth and flat surface of the pole plate, and can compress the volume of the battery cell and improve the energy density of the battery cell.

Reduce the internal porosity of the electrode sheet: roller compression reduces the porosity between the active substance, conductive agent and binder inside the electrode sheet, reduces the internal resistance of the battery and improves the battery performance.

Technical requirements for rolling process

Electrode thickness and appearance: the thickness, appearance and elongation of the electrode after rolling are output parameters that need to meet specific technical requirements.

Electrode thickness accuracy: the thickness of the finished product is about 80~ 200μm, and the thickness accuracy is not more than ± 3μm.

CONCLUSION

Through the above steps, the rolling process ensures the uniformity, density and stability of the lithium battery electrode sheet, which has a direct impact on the battery performance., production cost and qualification rate of lithium batteries, so it occupies a core position in the entire battery manufacturing process.

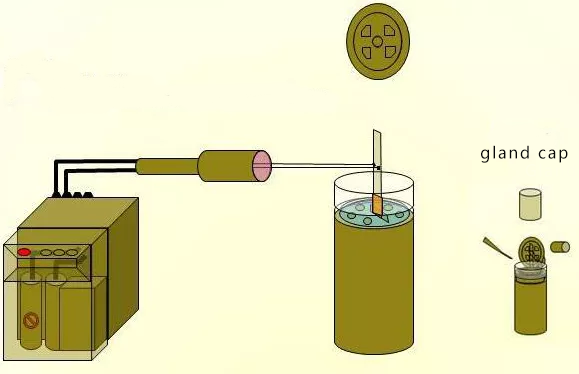

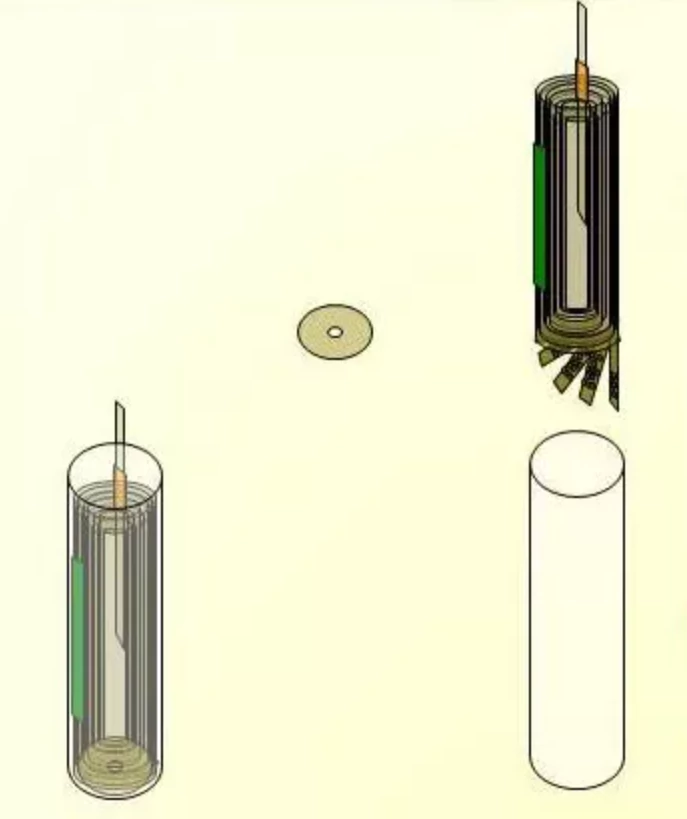

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

Storage at normal temperature

Storage at normal temperature Lithium batteries need to follow specific...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.