Product testing Product testing is a key link to ensure...

Critical control point

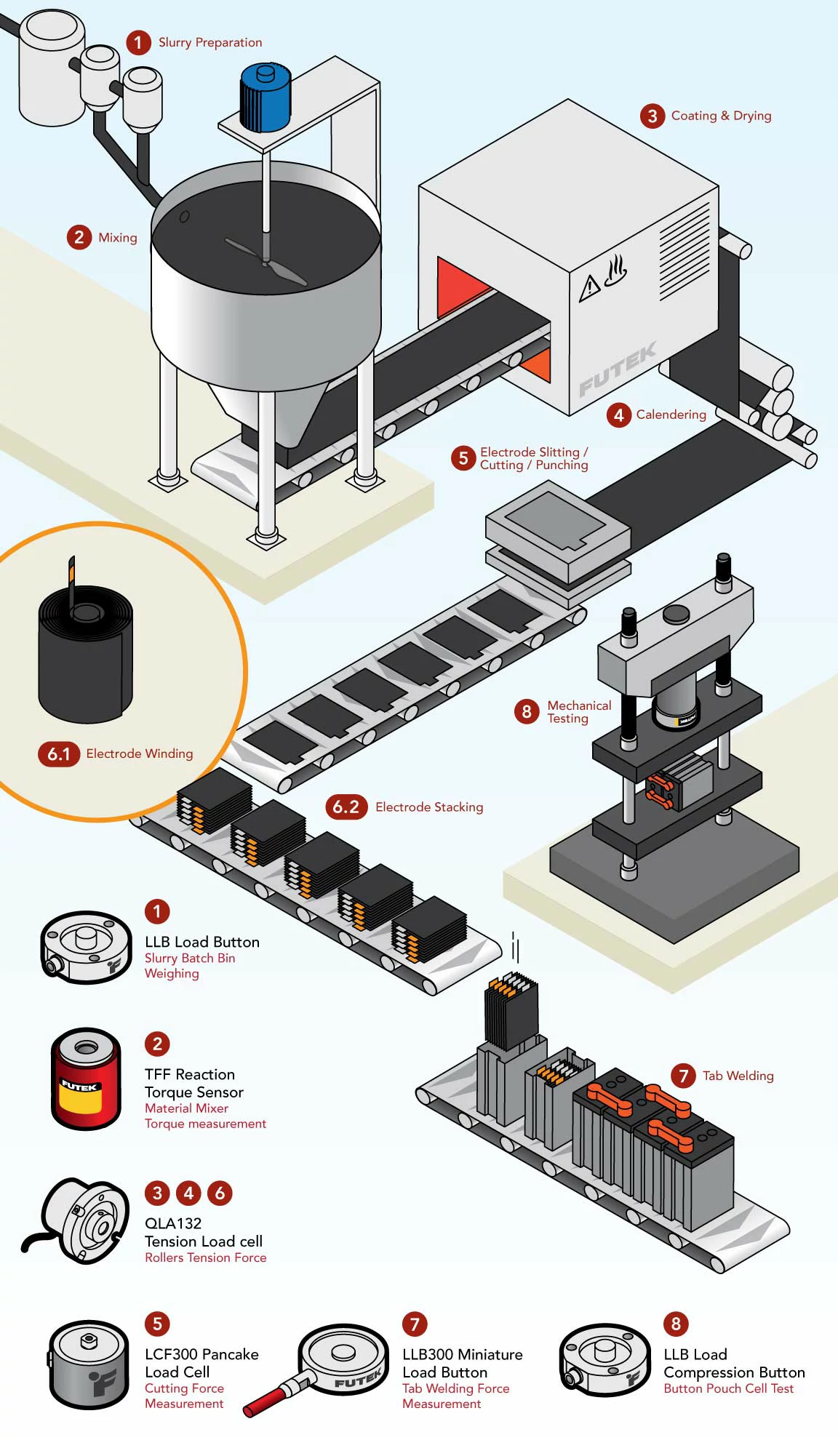

Critical control points are very important in the process of battery slurry preparation, which involves precise monitoring and adjustment of many links. The optimization of each control point is directly related to slurry quality, electrode performance, and final battery performance.

Critical control point

The key control points in the preparation of battery slurry are viscosity, mixing time and speed, solvent to binder ratio, dispersion of raw material and stability of slurry. The optimization of each control point can effectively improve the performance and production efficiency of the battery, so these key factors need to be accurately monitored and adjusted during the slurry preparation process to ensure high quality and stability of the battery.

Critical control points and their impact

The viscosity of the slurry

The viscosity directly affects the fluidity and coating quality of the slurry. Too high or too low viscosity can affect battery performance, so the viscosity of the paste needs to be precisely controlled to ensure that it is suitable for coating and adheres evenly to the electrode collector.

Viscosity control is the key to ensure slurry uniformity and coating performance, and must be kept within the appropriate range.

Mix time and speed

Mixing time and speed determine the uniformity and dispersion of raw materials. Too short mixing time may lead to uneven, too long may cause solvent volatilization, affect the stability of the slurry. It is necessary to reasonably control the mixing parameters to ensure that the raw materials are fully mixed and to maintain the stability of the slurry.

The control of mixing time and speed ensures the uniform dispersion and stability of the slurry, which directly affects the battery performance.

Ratio of solvent to adhesive

The ratio of solvent to binder affects the viscosity and coating properties of the paste. The appropriate ratio ensures that the slurry has good fluidity and adhesion, and too much solvent or adhesive will cause slurry problems, which will affect the battery performance.

Precise control of the ratio of solvent and adhesive to ensure moderate slurry viscosity is the guarantee of battery performance.

Dispersion of raw materials

The uniform dispersion of the raw material determines the performance of the electrode material, and good dispersion can improve the conductivity and cycle stability of the electrode. Poor dispersion can lead to poor electrode conductivity and affect the overall performance of the battery. Good dispersion ensures uniform slurry and helps to improve the electrochemical performance and stability of the battery.

Stability of slurry

The stability of the slurry ensures consistency in the production process and the long-term performance of the battery. The stable slurry avoids delamination and precipitation problems, ensuring uniformity during electrode coating and high battery consistency.

The stability of the slurry directly affects the coating quality and the consistency of the battery, and it must be ensured that the slurry remains stable during storage and use

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.