How is the superalloy spring designed in the battery safety...

Cooling systems for EPS inverters: key components and working principles

EPS inverters generate a lot of heat during operation, so an efficient cooling system is needed to maintain their performance and extend their service life. This article will detail the key components of the EPS inverter cooling system, including coolant/medium, cooling pump, radiator/cooler, heat exchanger, thermal materials, temperature control system and gas flow channels.

main content

The coolant/medium is the core of the cooling system and is responsible for transferring the heat generated by the inverter. According to whether the state changes during the cooling process, the coolant can be divided into two categories: single-phase and phase-change immersed liquid cooling. Single-phase liquid cooling eliminates the heat generated by the equipment by circulating the coolant, while phase-change immersion liquid cooling uses the boiling phase transition of the coolant to absorb heat. Choosing the right coolant is crucial to ensure the cooling efficiency of the inverter.

The cooling pump is the key device that pushes the coolant to circulate in the system, ensuring that the coolant can flow efficiently to transfer heat from the inverter to the radiator or heat exchanger. Cooling pumps need to be designed with durability, efficiency and noise levels in mind to ensure the long-term stability of the cooling system.

Radiator/cooler

The role of a radiator or cooler is to dissipate the heat from the coolant into the environment. They are usually made of metal and have a large surface area to increase the efficiency of heat transfer. Radiators can be air cooled or liquid cooled, depending on the design and application requirements of the cooling system.

Heat exchanger

Heat exchangers are used to transfer heat between the coolant and an ambient medium (usually air or water). In submerged liquid cooling systems, heat exchangers can transfer the heat from the coolant to the water supply, which then dissipates the heat to the environment.

Heat-conducting material

Thermal conductivity materials are used to improve the heat transfer inside the inverter, they can be thermal silicone sheets, thermal insulation materials, thermal tape and so on. These materials can effectively fill the gap between the inverter and the radiator, improve heat transfer efficiency and reduce thermal resistance.

Temperature control system

The temperature control system is responsible for monitoring the temperature of the inverter and adjusting the operation of the cooling system as needed. This may include controlling the speed of the cooling pump, regulating the operation of the fan, or activating additional cooling measures. The temperature control system can respond to temperature changes in real time based on a microcontroller, ensuring that the inverter operates within a safe temperature range.

Airflow passage

Airflow channels are part of the cooling system and are designed to direct the flow of air to help dissipate heat. In the air cooling system, the design of the airflow channel is very important to improve the cooling efficiency. Through reasonable layout and design, air flow can be maximized, thus improving the cooling effect.

CONCLUSION

In summary, the cooling system of an EPS inverter is a complex system that involves multiple components working together to ensure stable operation of the inverter under various conditions. Through careful design and selection of suitable coolants, cooling pumps, radiators, heat exchangers, thermal materials, temperature control systems and gas flow channels, the performance and reliability of the inverter can be significantly improved.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

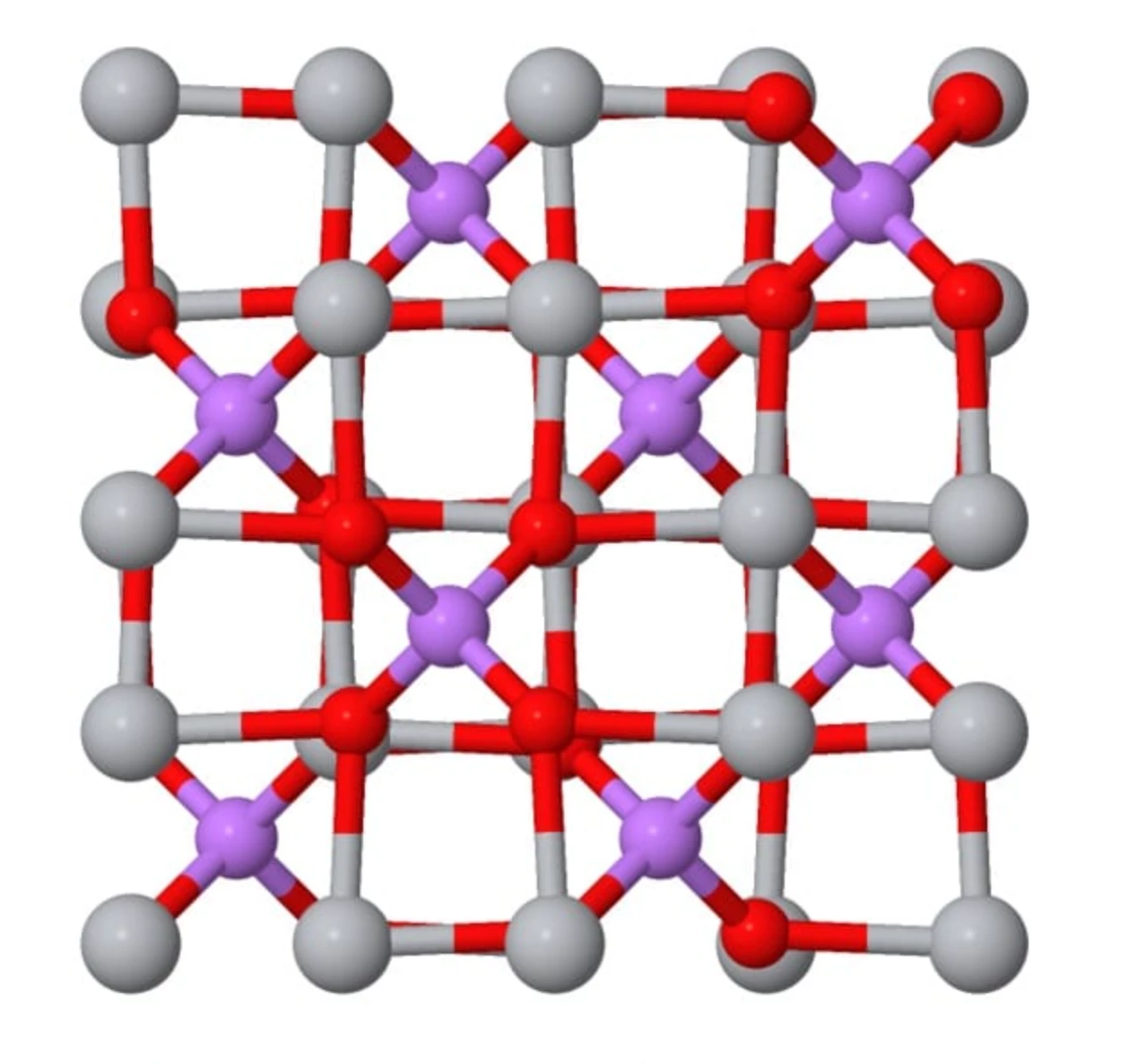

Negative electrode materials in EPS battery cell

negative electrode materials in EPS battery cell The negative electrode...

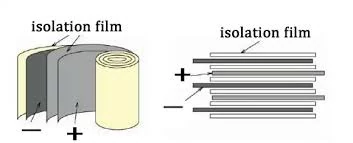

Isolation film material of EPS cell monomer: polymer

Isolation film material of EPS cell monomer: polymer In the...

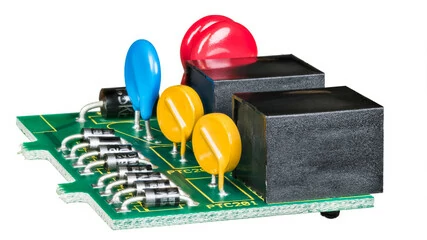

EPS inverter protection circuit analysis – overvoltage, overcurrent protection

EPS inverter protection circuit analysis – overvoltage, overcurrent protection Emergency...

EPS charging interface introduction

EPS charging interface The EPS (Emergency Power Supply) charging interface...

How does the inverter circuit work in EPS?

How does the inverter circuit work in EPS? The workflow...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.