Product testing Product testing is a key link to ensure...

Conductors and binders

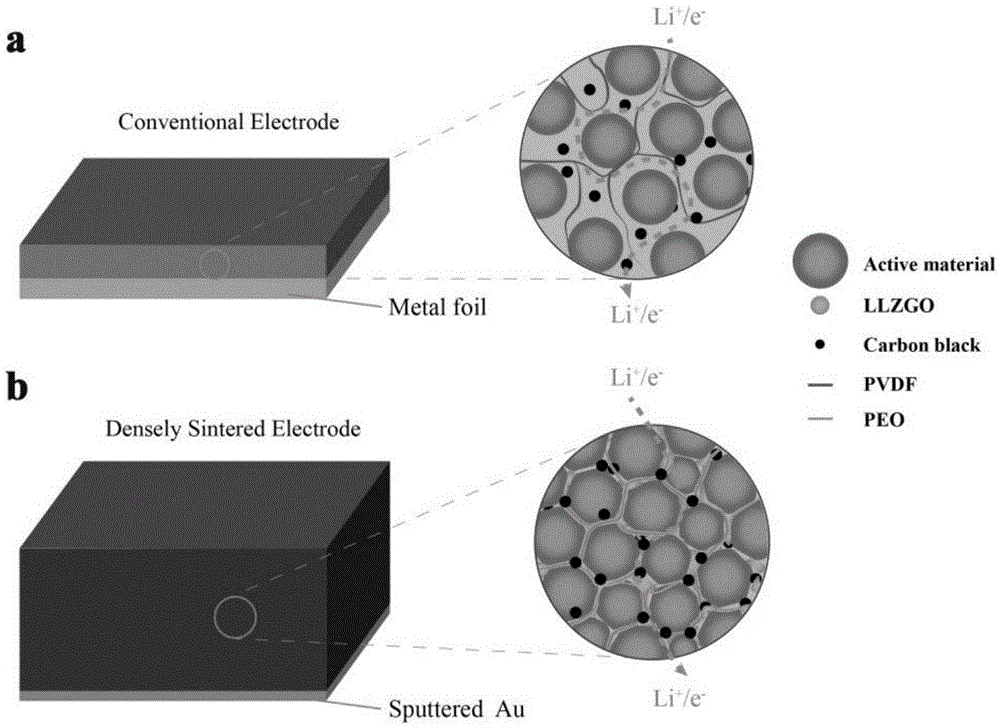

Such as carbon black and polyvinylidene fluoride (PVDF), help battery materials to maintain good electrical conductivity and structural stability.

Conductors and binders

The role of conductive agents and binders in lithium batteries is indispensable. The conductive agent improves the conductivity of the electrode and enables the battery to perform well in high power applications. The binder ensures the stability of the electrode and prolongs the service life of the battery. With the development of lithium battery technology, how to optimize the performance of these two materials will be an important direction to improve battery performance and reduce costs.

Role and importance

The main role of the conductive agent

Improve the conductivity of the electrode: Electrode materials, such as active materials (such as lithium nickel-cobalt manganate in the positive electrode or graphite in the negative electrode), are usually themselves less conductive. The addition of a conductive agent can improve the electron conductivity of these materials, ensuring that electrons can flow during the battery charging and discharging process.

Enhanced battery performance: Good electrical conductivity can ensure that the battery can still work stably when discharged at high rates, reduce energy loss, and improve the efficiency and power density of the battery.

The main role of the Binder

Improve the structural stability of the electrode: the binder firmly binds the electrode material together to prevent the electrode material from falling off or expanding during the charge and discharge process, so as to ensure the long-term stability of the battery.

Improve cycle life: By enhancing the stability of the electrode structure, the binder helps the battery maintain the integrity of the electrode during multiple charge and discharge processes, reducing electrode failure and improving the cycle life of the battery

Interaction between conductive agent and binder

The role of the conductive agent and the binder in the electrode is closely related. The conductive agent mainly enhances the conductivity of the electrode, while the binder maintains the structural stability of the electrode. In the electrode manufacturing process, they are usually mixed with active materials, solvents, etc., which are coated onto a fluid collector (such as aluminum foil or copper foil) by a coating process. The ratio, selection and interaction of the two will directly affect the performance of the battery.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.