How is the emergency stop button of DC charging pile...

Components of the heat dissipation system

The heat dissipation system of the charging module is a key technology to ensure the stability and safety of the module during high power operation.The heat dissipation system of the charging module consists of several key components that work together to ensure that the module can effectively dissipate heat when operating at high power. The following are the main components of the heat dissipation system:

Main component

The heat sink is the core component of the heat dissipation system and is usually made of a material with good thermal conductivity such as aluminum or copper. Its role is to absorb the heat generated inside the module and transfer it to the air or the coolant.

Fans are used to force air flow and accelerate heat dissipation from the surface of the radiator into the surrounding environment. The speed and number of fans can be adjusted according to the demand for heat dissipation.

A heat pipe is an efficient heat conduction device that quickly transfers heat from the hot spot of the module to the radiator. Heat pipes usually contain a working medium that evaporates at the hot end and condenses at the cold end, circulating back and forth to transfer heat.

Liquid cooling plate is the key component of liquid cooling and heat dissipation system. It is usually made of metal plate, and there are channels for the coolant to flow inside. The liquid cooling plate is in contact with the heat source of the module, absorbs heat and passes it to the flowing coolant.

Coolant is the heat exchange medium in a liquid cooling system, usually a mixture of water and antifreeze, or a special cooling oil. It circulates between a liquid-cooled plate and a radiator, absorbing heat and dissipating it to the environment.

The water pump is used to drive the circulating flow of coolant in the liquid cooling system, ensuring that the coolant can continuously absorb heat from the heat source and transfer it to the radiator.

Cooling towers are used to dissipate heat from the coolant to the environment. In some systems, fan-assisted radiators may be used, or a cooling tower with natural convection may be used.

The temperature sensor is used to monitor the temperature of the module and the heat dissipation system to ensure that the system operates within a safe temperature range. Data from the sensors can be used to control fan speed or water pump flow to optimize heat dissipation.

According to the feedback signal of the temperature sensor, the control unit adjusts the working state of the fan and water pump to achieve the best heat dissipation effect.

Interfaces and pipes are used to connect various components in a liquid cooling system, such as liquid cooling plates, water pumps, radiators, and coolant storage vessels.

Together, these components form the heat dissipation system of the charging module, and they work together to ensure stable operation of the module under high load and prevent overheating, thus improving the reliability and life of the module.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

The introduction of tap-changer of DC charging pile transformer

The introduction of tap-changer of DC charging pile transformer The...

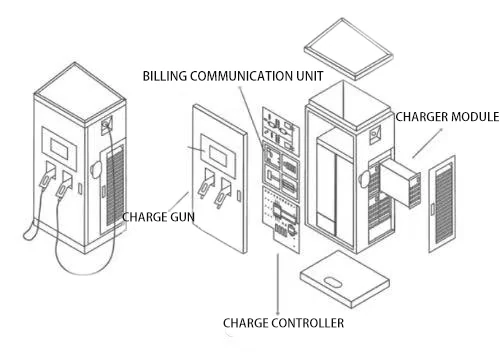

What are the components of a DC charging pile

This paper will introduce the main components of DC charging...

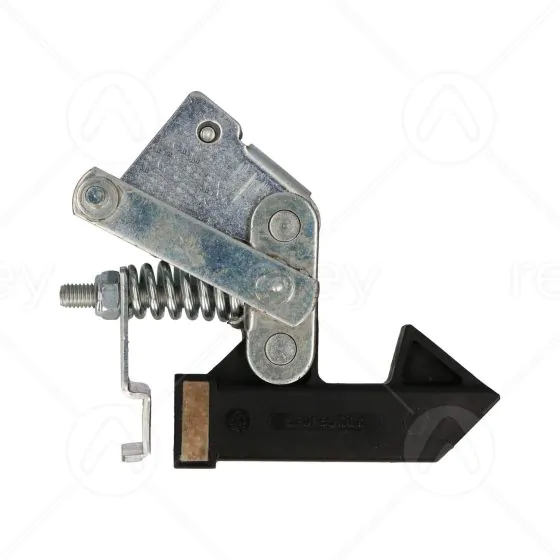

Release mechanism in mechanical locking device

Release mechanism in mechanical locking device In the design of...

An introduction to the transmission cable in the display

An introduction to the transmission cable in the display Main...

Contact Material of DC charging pile

Contact Material of DC charging pile Main component Concept: DC...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.