Type of BMS Classification by structure Centralized BMS All monitoring...

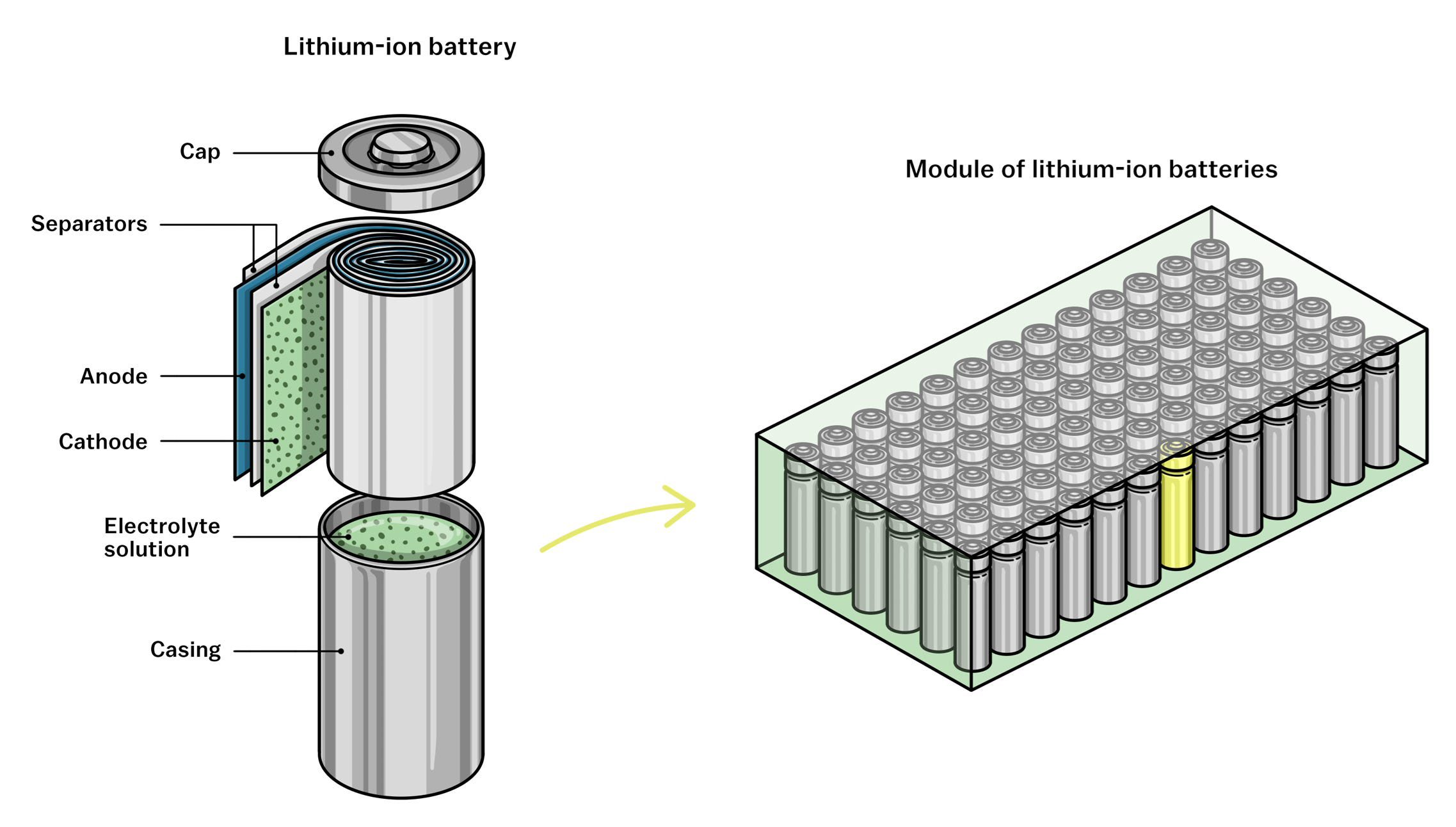

Components of a battery cell

Battery cell is the basic unit of battery pack, and its performance and reliability are closely related to the design and materials of internal components. This paper will detail the main components of the single cell battery, including the pole plate, electrolyte, diaphragm paper, sealing ring, positive cap and battery shell, in order to understand their important role in the working process of the battery.

The pole piece is the core part used to store and release electrical energy in a single battery, which is usually divided into two types: positive and negative.

Cathode: The cathode material usually uses lithium-rich metal oxides (such as nickel-cobalt-manganese oxide, lithium cobalate, etc.), which have high energy density and good cycling performance.

During battery discharge, lithium ions migrate from negative to positive electrodes and release electrical energy in the process.

Negative electrode: The negative electrode is generally made of graphite or silicon based materials, which has good conductivity and lithium ion storage capacity. During charging, lithium ions are transported from the positive electrode to the negative electrode and embedded in the lattice of the negative material.

The manufacturing process of the pole sheet involves processes such as coating, drying, compaction and cutting, which directly affect the capacity and cycle life of the battery.

The electrolyte is an important conductive medium in the battery cell, and its main function is to support the conduction of lithium ions. Common components of the electrolyte are organic solvents (such as carbonates) and dissolved lithium salts (such as LiPF6). These liquids can efficiently conduct lithium ions during charging and discharging, while being chemically stable enough to prevent side reactions.

Material: The diaphragm is usually made of high polymer such as polyethylene (PE) or polypropylene (PP), which has excellent electrical insulation and chemical stability.

Porosity and thickness: The porosity and thickness of the diaphragm have an important impact on the internal resistance, capacity and cycling stability of the battery. Too thick diaphragm will increase internal resistance, while too thin may lead to safety hazards.

The sealing ring is an important sealing device in the single cell, its main function is to prevent the leakage of electrolyte and the entry of external pollutants. The sealing ring is usually made of high temperature and corrosion resistant materials such as fluorine rubber.

Function: The sealing ring ensures the safety of the battery in the process of charging and discharging, and avoids the interference of internal and external environment.

Design: The design of the sealing ring should consider the pressure variation inside the battery to ensure that it can maintain effective sealing performance under high temperature and high pressure conditions.

The positive cap is a closed structure at the top of a single cell that protects the positive electrode and provides the current connection. The positive cap is usually made of metal material and designed to have a conductive structure connected to the external circuit of the battery.

Conductivity: The design of the positive cap needs to ensure a tight connection to the pole sheet to achieve good current conduction.

Safety: The positive cap also assumes a certain safety protection function to prevent external objects from entering the battery interior, and is used with a safety valve to prevent the risk of gas accumulation.

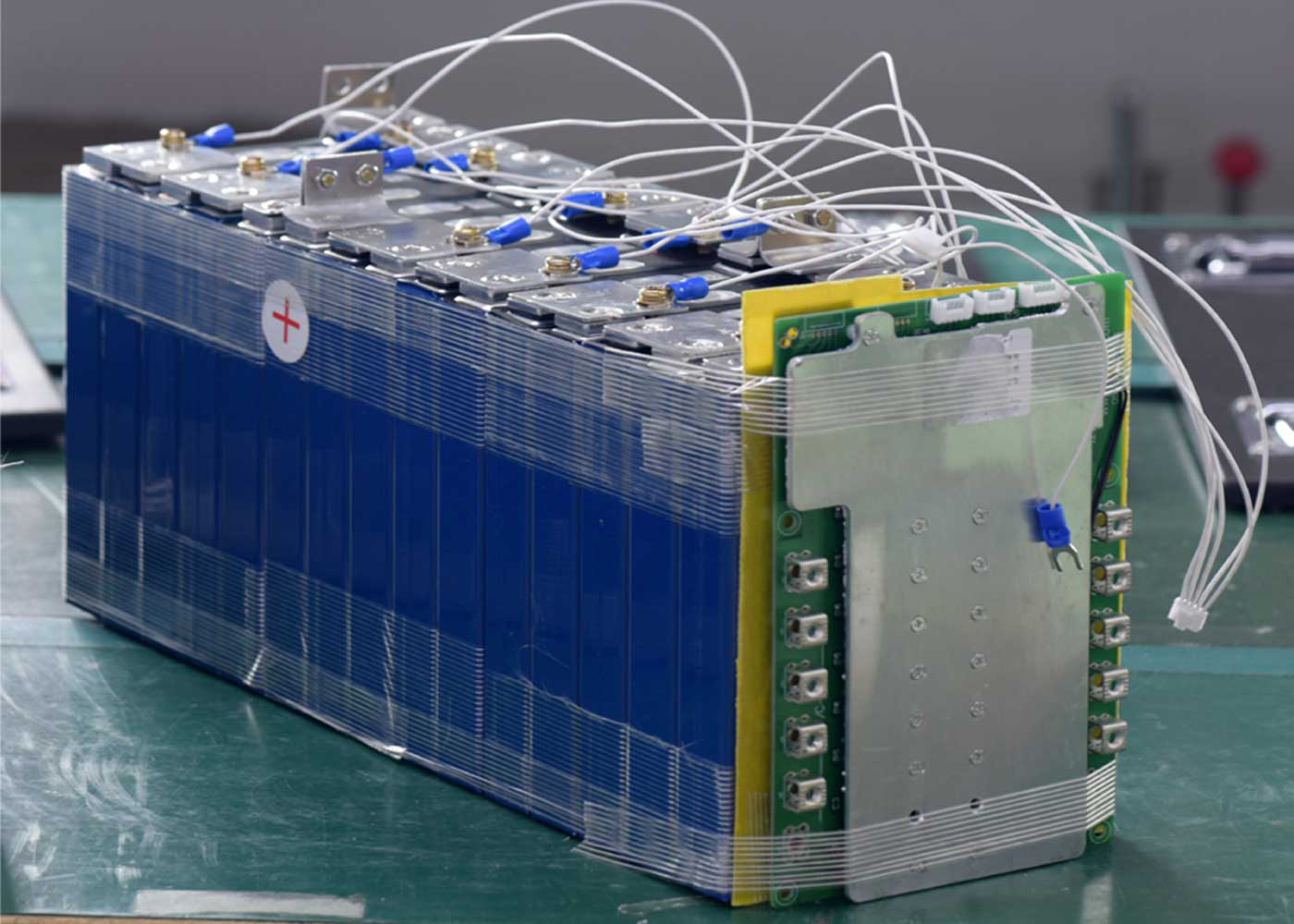

Battery case

The battery shell is the outer protective layer of the single cell, designed to provide physical protection and structural support. Battery cases are usually made of corrosion-resistant, high-strength materials such as aluminum alloy or high-strength plastic.

Protection: The battery case can prevent external impact, moisture and other environmental factors from affecting the battery interior, thereby improving the safety and life of the battery.

Heat dissipation: A good battery shell design will also take into account the heat dissipation function to effectively dissipate the heat of the battery in the process of charging and discharging, reducing the risk of overheating.

In order to ensure the reliability and safety of the lithium iron phosphate battery in use, the finished battery must go through a series of strict tests. Including the battery appearance inspection, electrical performance test, safety test and environmental adaptability test.

Conclusion

The performance and safety of single battery depend on the cooperation of each component. Each component such as the pole sheet, electrolyte, diaphragm paper, sealing ring, positive cap and battery case plays a crucial role in the charging and discharging process of the battery. A deep understanding of the functions and characteristics of these components will help to promote the development of battery technology and improve the application performance and safety of batteries. With the progress of science and technology, the design and materials of single cell batteries are also evolving, which provides the possibility of more efficient and secure energy storage solutions.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

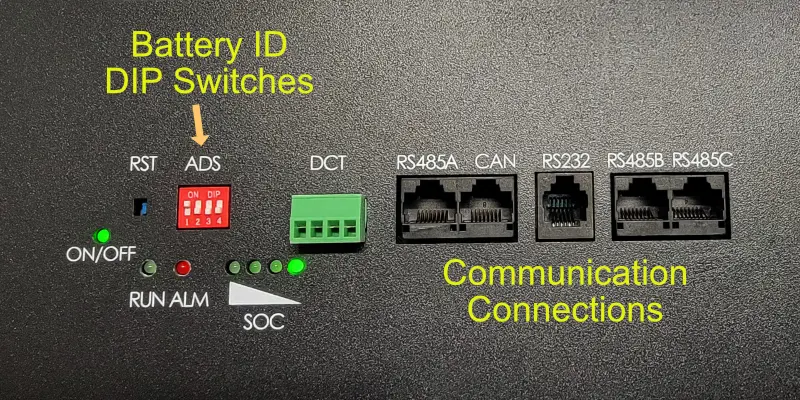

Communication mode of battery pack

Communication mode of battery pack With the rapid development of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.