Check the alignment Alignment test in the production process of...

Check the alignment

Alignment test in the production process of lithium batteries is an important step to ensure battery performance and safety. The following is a detailed description of checking alignment:

Verify the purpose and importance of alignment

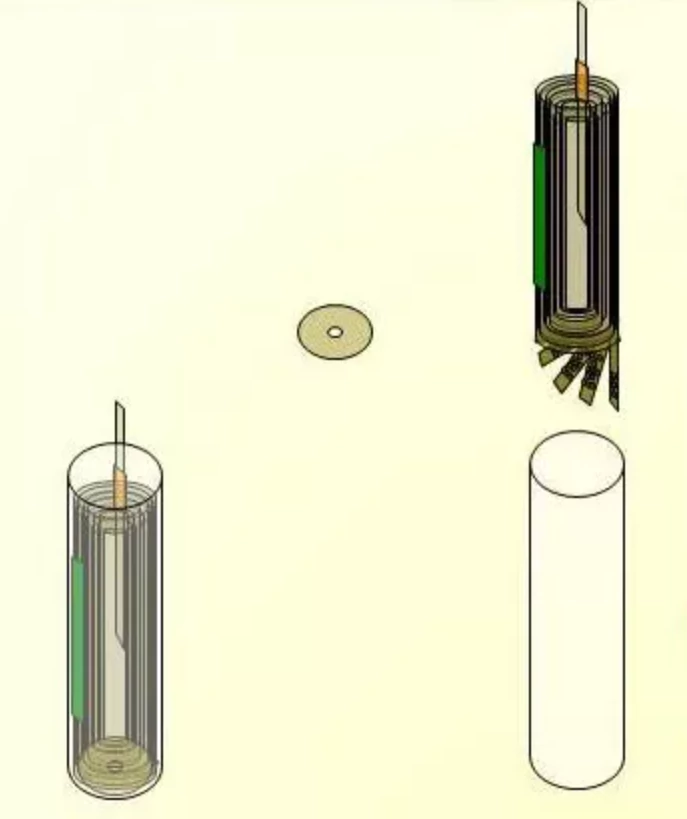

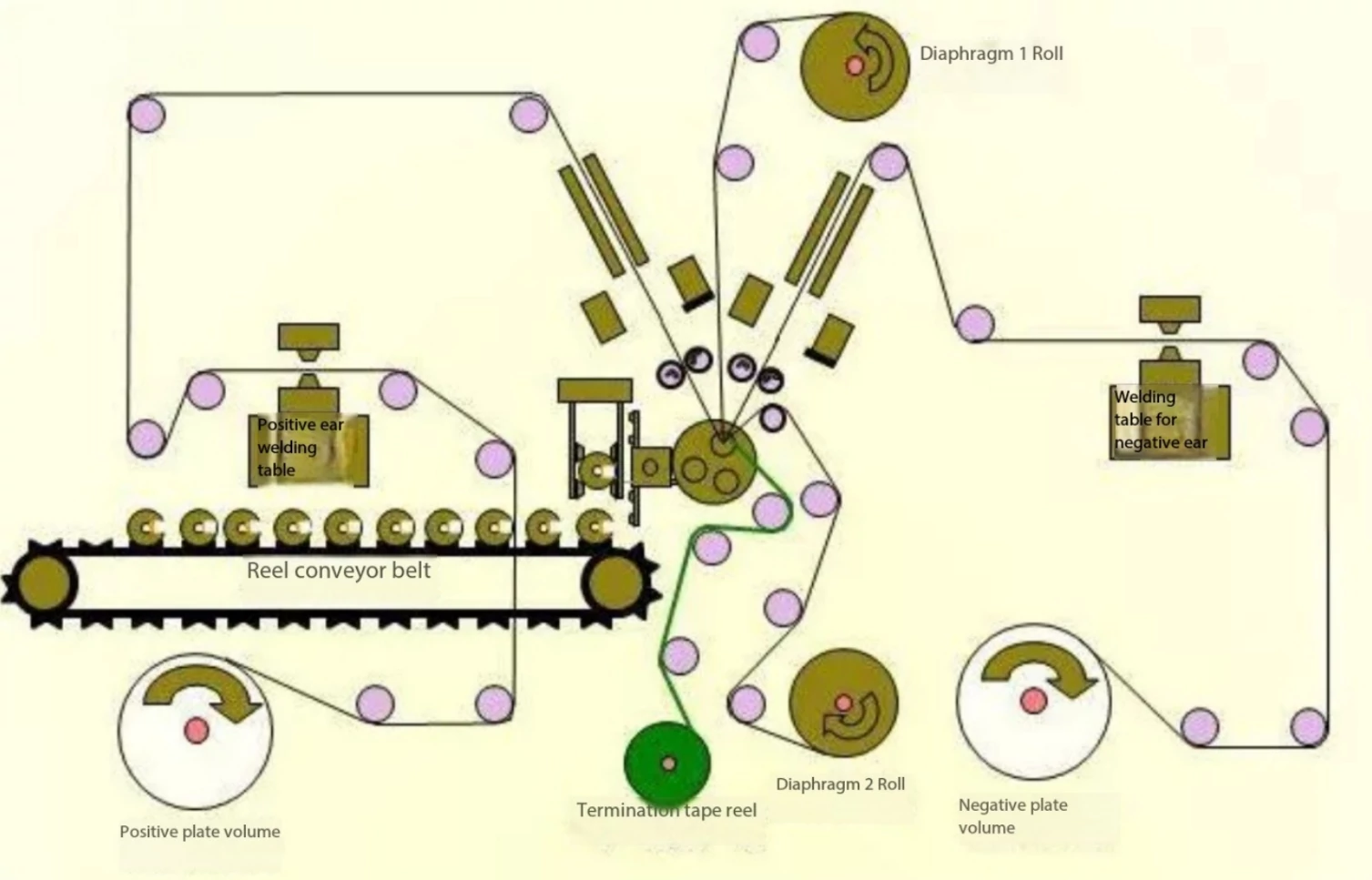

Inspection alignment mainly refers to the detection of the relative position accuracy of the edge position of the positive and negative pole sheets in the stacking or winding process in the manufacturing process of lithium batteries. This step is essential to ensure the stability and consistency of the battery's internal structure and is directly related to the battery's energy density, safety and service life.

Technical principle and method of checking alignment degree

Die punching technology: The electrode sheet material is stamped with a precisely designed die to obtain the desired shape and size of the electrode sheet. The accuracy and stability of the die have a direct influence on the alignment of the pole plate.

Laser cutting technology: The use of laser cutting technology to cut the pole plate, because of its high precision and high efficiency and is widely used, can improve the alignment of the pole plate.

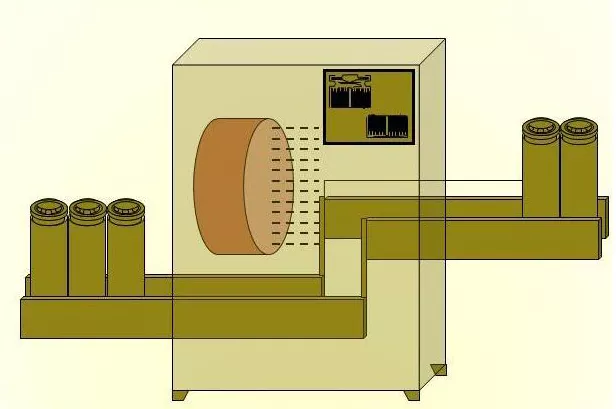

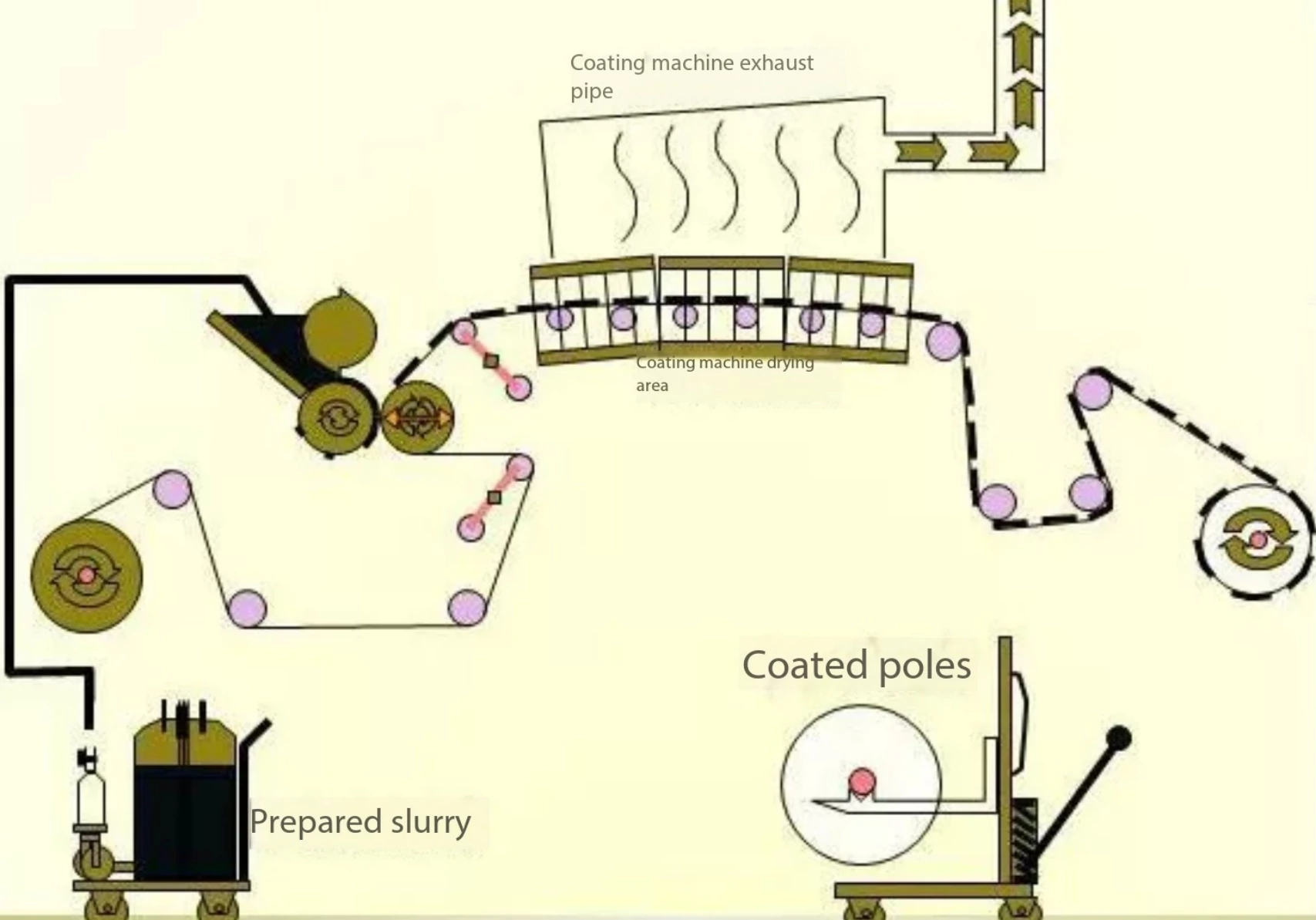

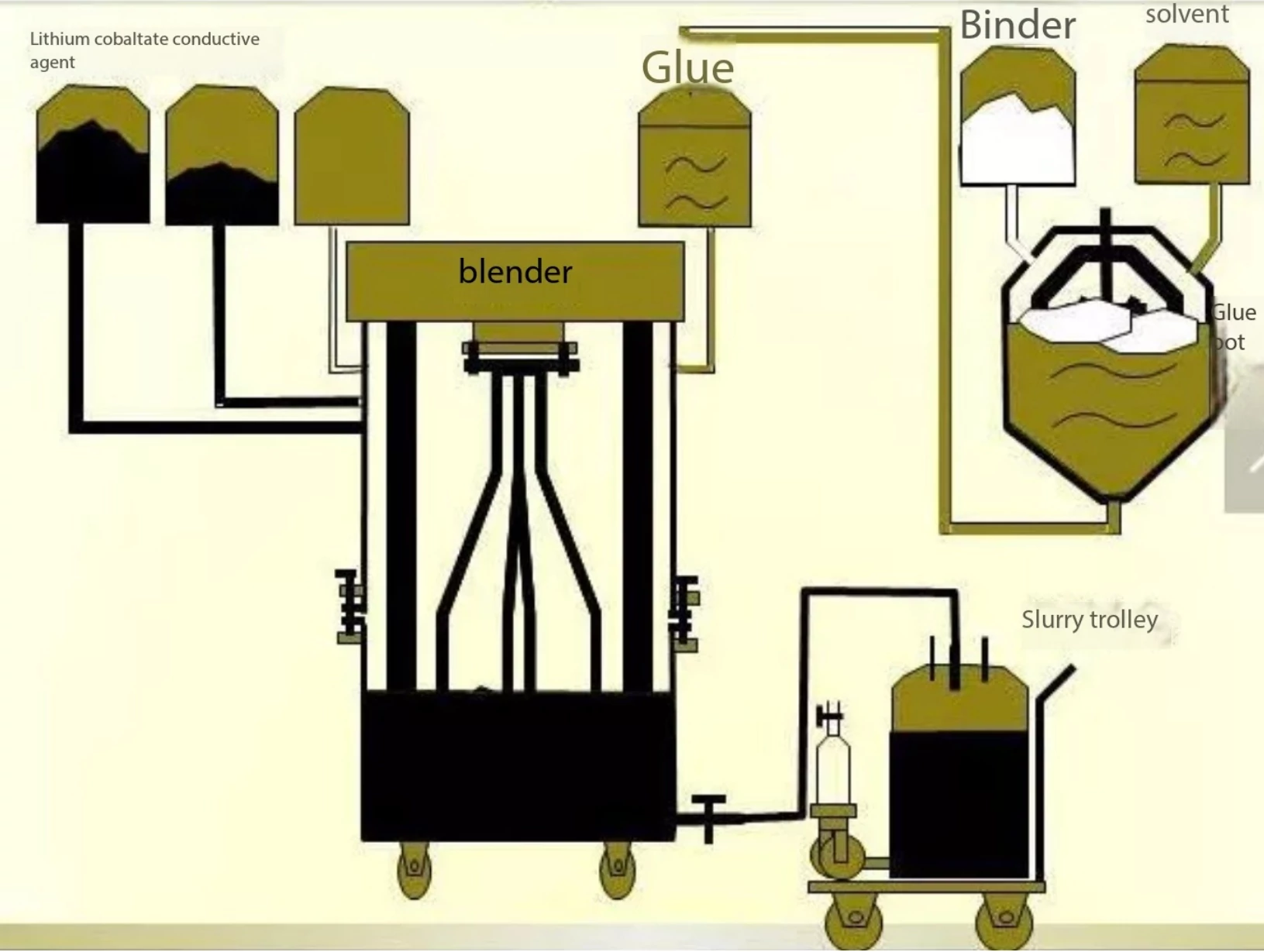

Coating alignment test method: In the coating process, the front and back alignment is an important parameter of the coating process. The invention provides a coating alignment degree detection method, a detection device and a coating device to solve the problem that the existing alignment degree detection method and device are not convenient to detect the alignment degree of two wet surfaces that are not dried after coating, and improve the accuracy of the detection result.

Examine the factors that influence alignment

Material characteristics: The material and thickness of the pole will affect its alignment during die cutting or winding.

Process parameters: die cutting speed, die temperature, coating parameters, etc., will affect the alignment of the pole plate.

Equipment accuracy: The accuracy of die cutting equipment and the stability of coating equipment are also important factors affecting the alignment degree.

Check the quality control of alignment

In the manufacturing process of lithium batteries, quality control is a key link to ensure battery performance and safety. Any small defect can affect battery life, efficiency and safety. Therefore, from raw material selection and battery assembly to finished product inspection, strict quality control processes are required.

CONCLUSION

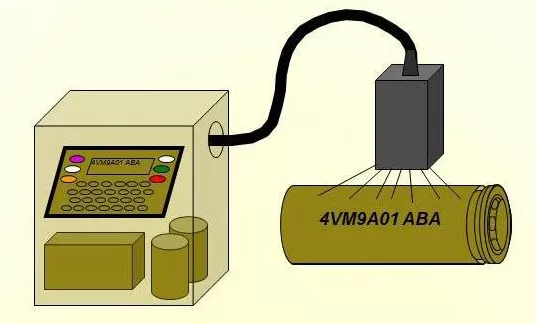

Through the accurate control and detection of the alignment degree, the internal structural stability of the lithium battery can be ensured and the overall performance and safety of the battery can be improved.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.