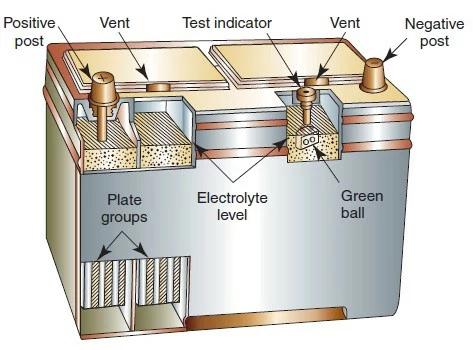

Quality control and safety testing Quality control and safety testing is an important part of the battery production process to ensure the performance, safety and long-term reliability of the battery. Through strict quality control and comprehensive safety testing, it can effectively prevent battery failure, extend battery life, and ensure the safety of users and the environment. Quality control and safety…