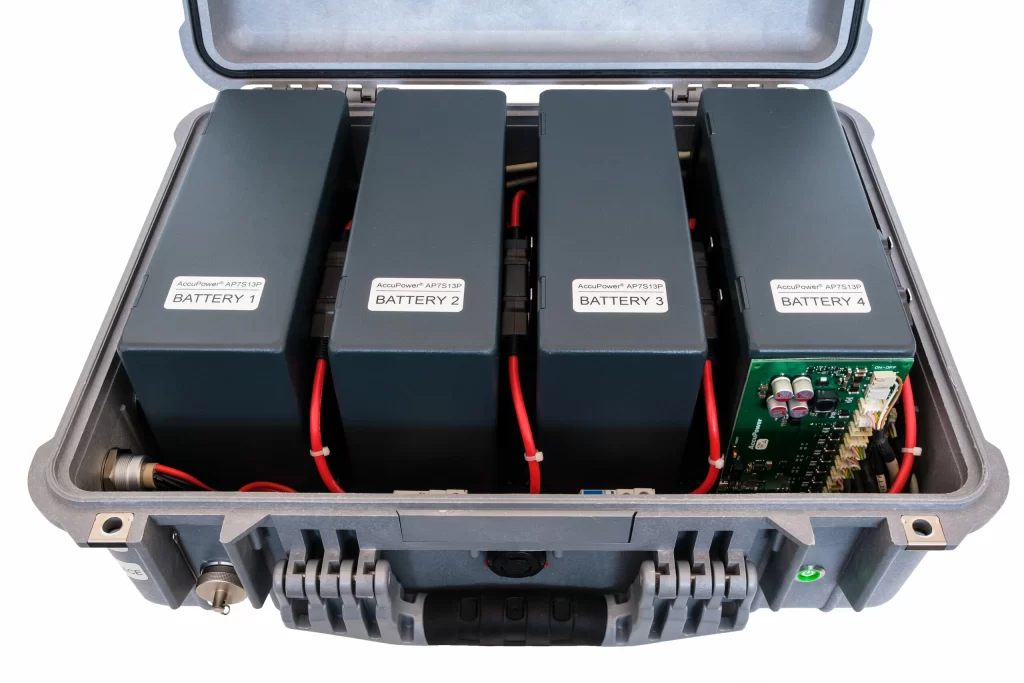

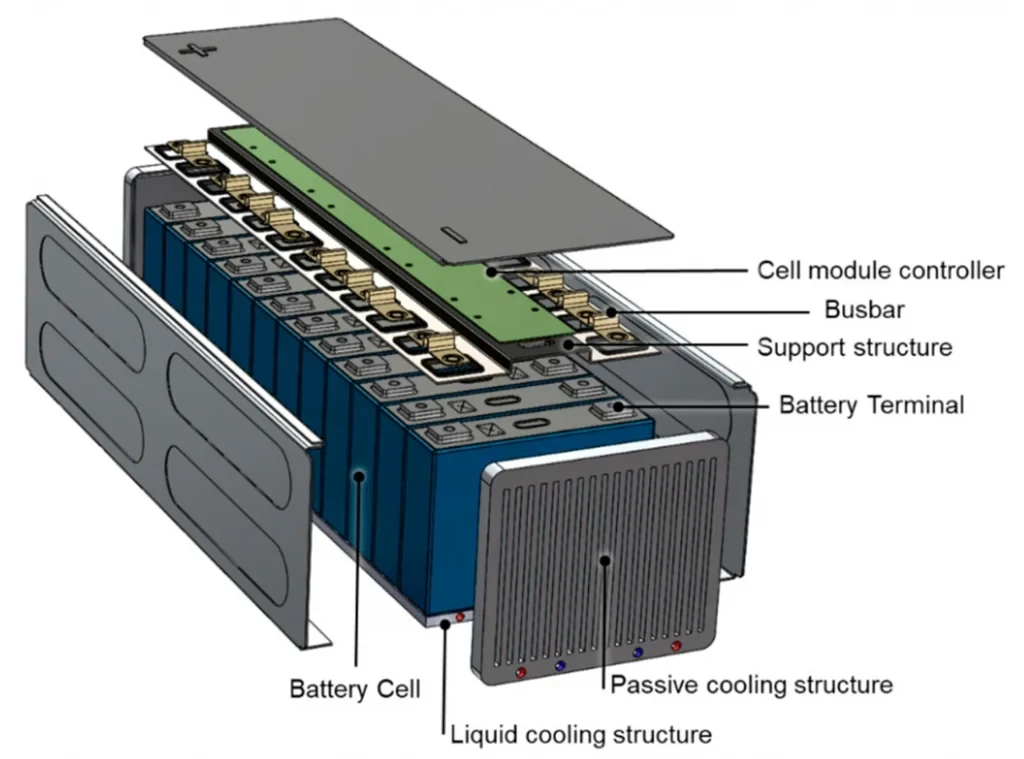

Shell encapsulation and assembly fixed In the battery pack production process, the packaging and assembly of the case is a key step to ensure the safety, stability and durability of the battery module. This process involves not only physically protecting the cell and its internal components, but also optimizing the thermal management, shock resistance and mechanical strength of the battery…