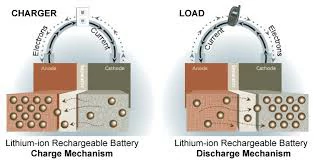

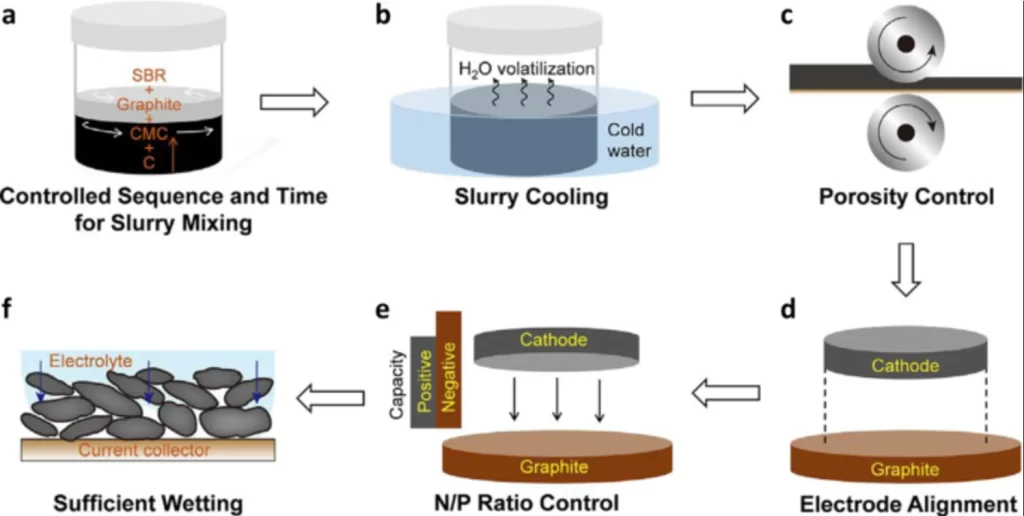

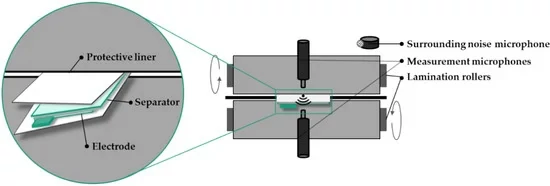

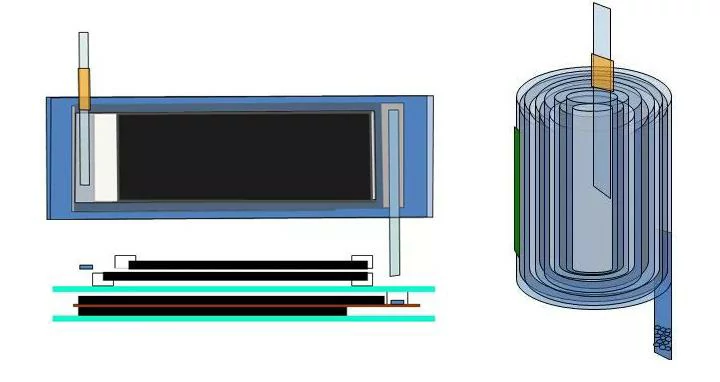

Formation and separation Formation and volume separation are important steps in the battery production process, which are mainly used to improve the performance and stability of the battery and ensure the balance of the battery pack. This process usually occurs after the battery assembly is completed, after the initial sealing, injection and other processes, the purpose is to activate the…