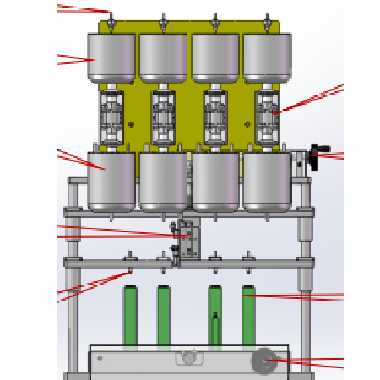

Maintain the battery module after the capacity divider test Follow-up maintenance of the battery module after the capacity division test includes the following aspects: Battery pack connection point check Check the connection points of the battery pack to ensure tight contact and no oxidation, and apply petroleum jelly to prevent further oxidation. Appearance inspection Check the appearance of the battery…