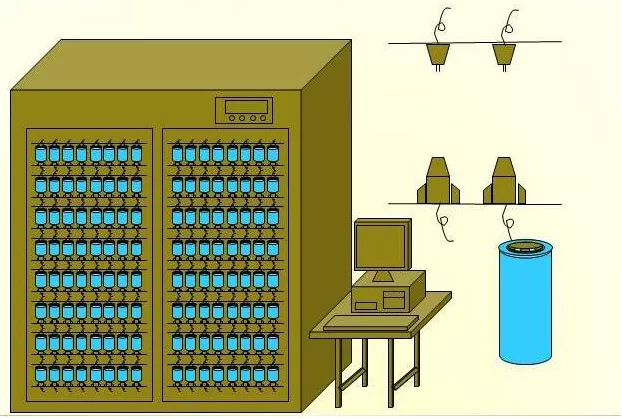

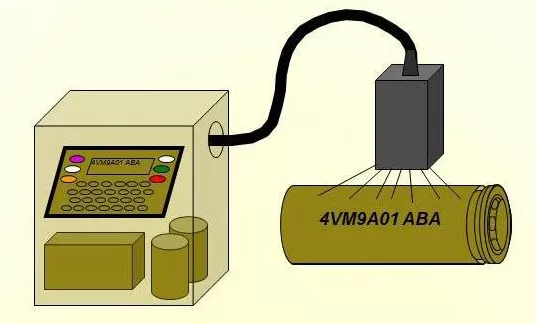

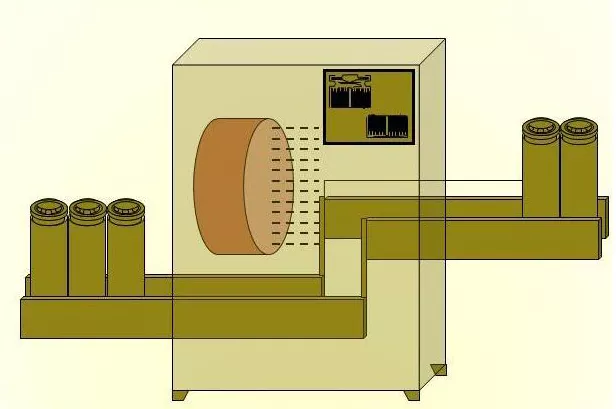

Partition Capacity separation is a key step in the production process of lithium batteries, the main purpose of which is to carry out capacity separation and performance screening classification of batteries. The following is a detailed introduction to the volume separation process: The concept of partitioned volume Capacity separation refers to the fixed requirements of the environment, when the lithium-ion…