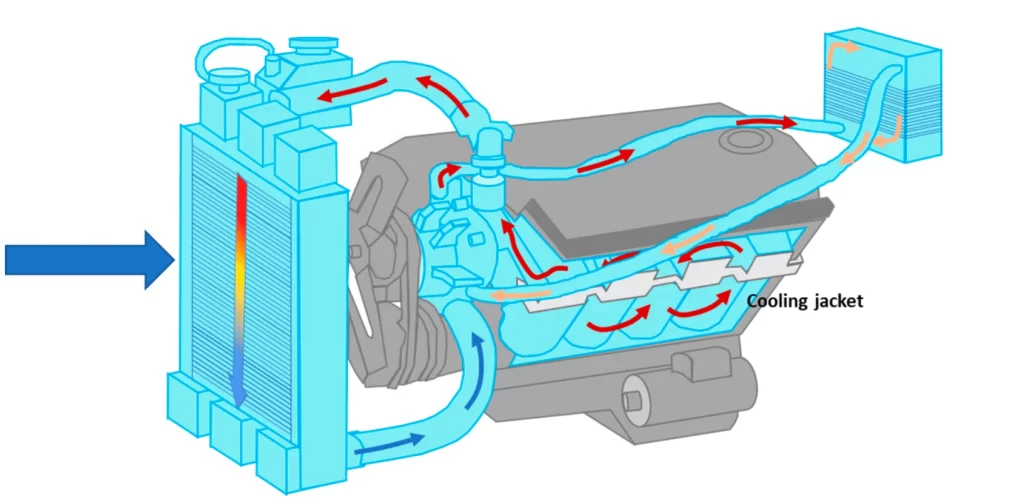

Introduction of cooling pump in EPS cooling system 2 In an emergency power system (EPS), one of the key factors to ensure the stable operation of the equipment and extend its service life is effective heat dissipation management. Among them, the cooling pump, as an important part of the cooling system, plays a vital role. This paper will introduce the…