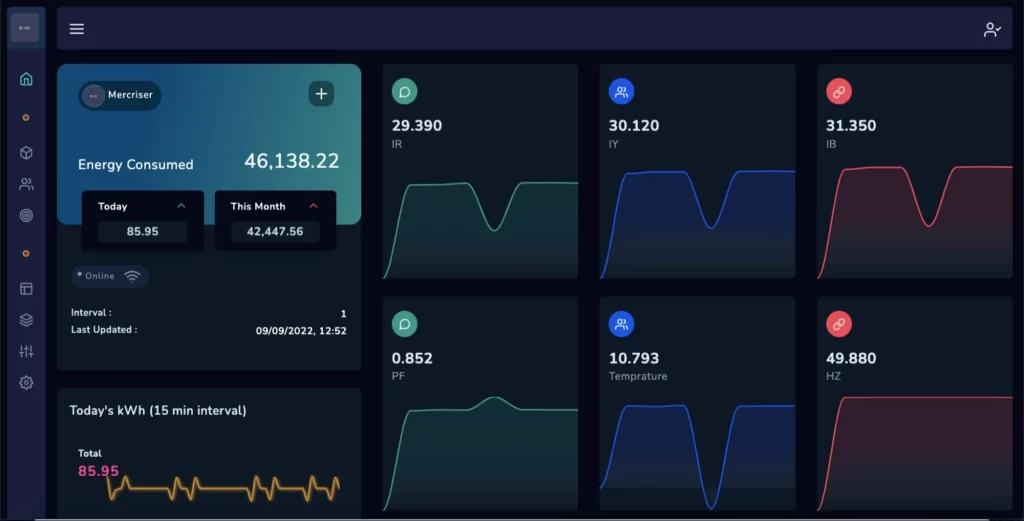

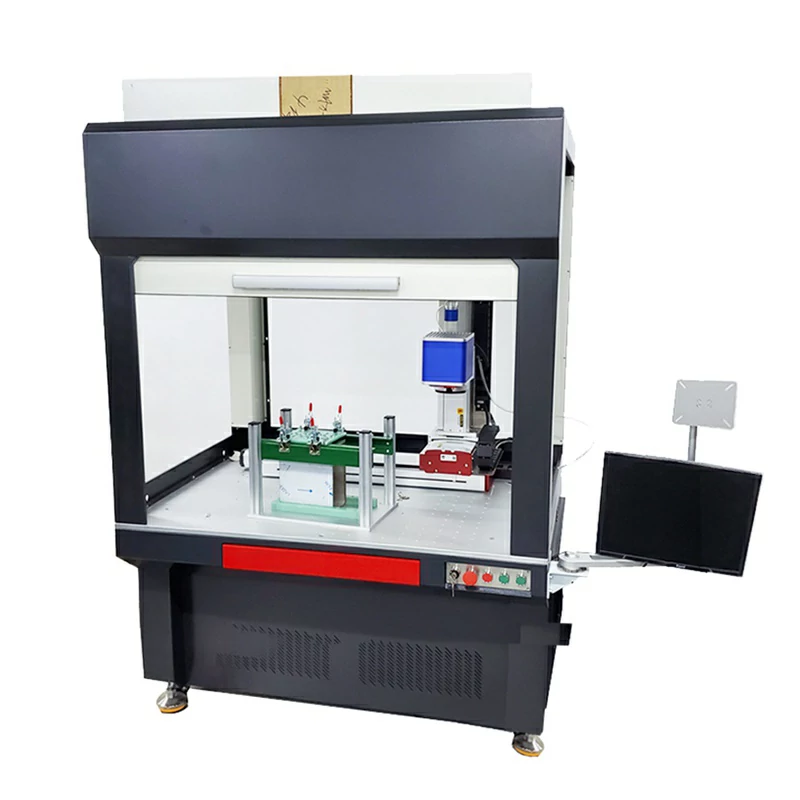

EMS An energy management system, or EMS, is a collection of software and hardware for monitoring, controlling, analyzing, and optimizing energy systems. It realizes efficient management and optimal allocation of energy through real-time monitoring and intelligent control of all aspects of energy production, distribution and consumption. In the energy storage system, EMS especially refers to the system used to manage…