Analysis of the rated voltage of the battery pack In...

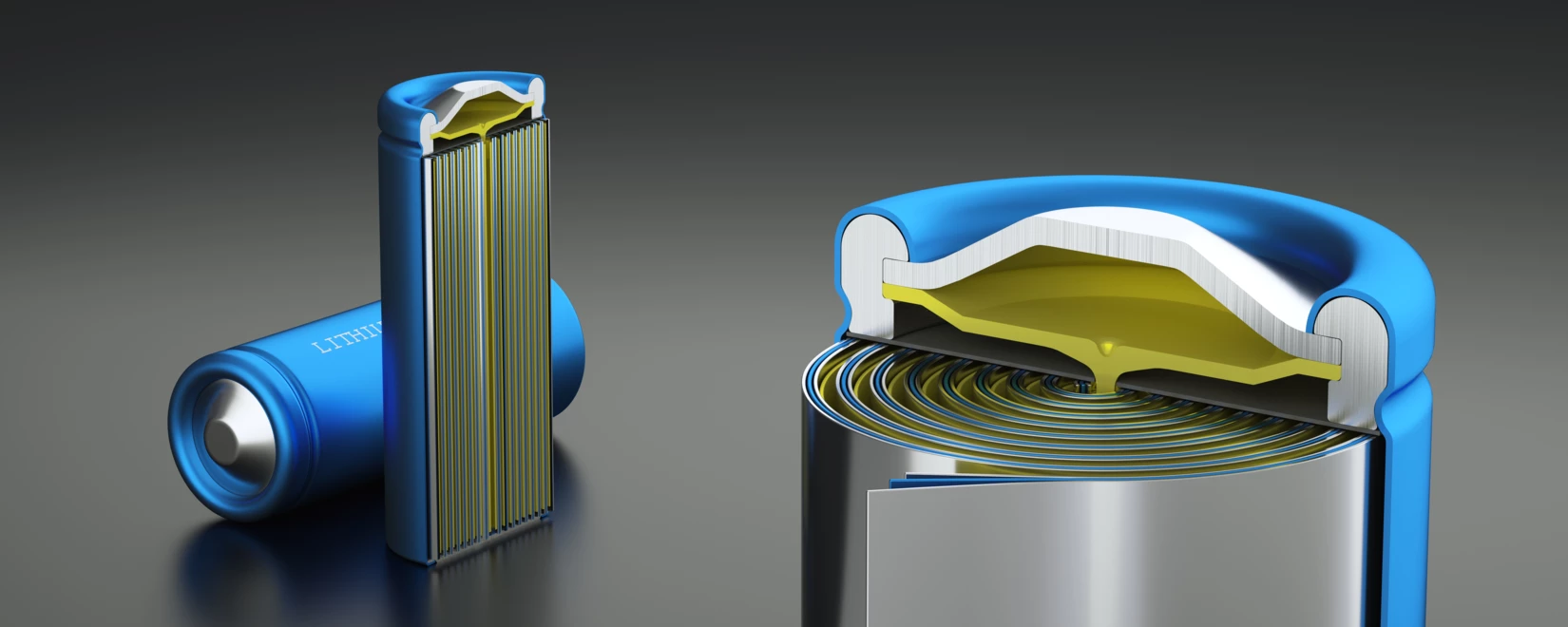

Capacity testing of single cell batteries

As the most basic part of the battery system, the capacity of the single battery is directly related to the performance and availability of the whole battery system. Capacity testing is an important step to evaluate the performance of the battery, which can help us understand the energy storage capacity and actual use of the battery. In this article, we will discuss the operation process and the required equipment for the capacity test of single battery.

what is the single battery capacity

The capacity of a single battery is usually expressed in milliamp hours (mAh) or ampere-hours (Ah), reflecting the amount of power it is able to store and release under certain conditions. The size of the capacity directly affects the battery life and power support ability. Capacity testing can help determine the actual performance, service life, and health of the battery.

Operation process of capacity test

Preparation

Select test battery: Select the single battery to be tested and ensure that the initial state of the battery (such as charging state, usage history, etc.) is known.

Environmental Preparation: Ensure that the temperature and humidity of the test environment comply with the battery manufacturer's recommendations, which generally recommend testing at a room temperature of 25°C.

Configuration of test instruments

Use a battery tester or electrochemical workstation to configure the corresponding test parameters, including discharge current, cut-off voltage and test duration.

charging

Fully charge the battery according to the battery charging specification. Constant current and constant voltage charging is usually used to charge the battery to its rated voltage and then hold it for a period of time to ensure that the battery is full.

Setting discharge parameters

Set the test instrument according to the selected discharge current. The discharge current can be set according to the rated capacity of the battery and the application requirements, and the common discharge rate is C/5, C/3, C or 1C.

Discharge test

Start the discharge test. Battery voltage and current changes were recorded. Monitor the temperature of the battery during the test to prevent damage caused by overheating. Discharge to the set cut-off voltage (usually set according to the battery type, lithium batteries are generally 2.5V or 3.0V).

Data recording and analysis

In the discharge process, the discharge time, durability, discharge capacity (mAh) and other data were recorded.

After the test, the discharge capacity is calculated to determine the actual capacity of the battery and compare it with the rated capacity.

Charge and discharge cycle test (optional)

To evaluate the battery performance more comprehensively, multiple charging and discharging cycle tests can be performed to observe the battery capacity decay.

Required instruments

The following instruments are essential for single battery capacity testing:

Battery tester

A device specifically designed for battery charge and discharge testing is able to provide accurate control of charge and discharge and record data such as voltage, current and temperature of the battery.

Electrochemical station

Provide more flexible test function, can carry out static and dynamic electrochemical test, suitable for research and development projects.

Temperature monitoring equipment

Monitor the temperature changes of the battery during charging and discharging to ensure that the battery operates within a safe range.

Data acquisition system

The test data were recorded in real time, the discharge capacity was calculated, and a report was generated for analysis and comparison.

Precautions

Safety: Safety procedures should be followed during testing. Ensure that the environment is well ventilated to prevent risks caused by battery leakage or short circuit.

Standardization: Test in accordance with relevant standards (such as IEC 62133, etc.) to maintain consistency and comparability of tests.

Battery condition: Ensure that the test battery is in good working condition and avoid using damaged or aged batteries for testing.

Conclusion

The capacity test of single battery is an important part of battery performance evaluation, which can provide important data support for the development, application and management of battery. Through the standard operation process and accurate instrument equipment, the capacity of the battery can be measured effectively, which provides the basis for the optimization and application of the battery. In the future development and application of battery, capacity testing will continue to play an indispensable role.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Cycle life test of single cell battery

Cycle life test of single cell battery With the development...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.