A highly integrated backup power solution for solar home energy...

BDU

Introduction: BDU is directly in contact with high voltage and large current, and its core function is responsible for the on-off of the main circuit, so BDU is also called the battery intelligent disconnection unit. On the basis of the traditional disconnection and on-off, more monitoring and protection mechanisms are gradually added to improve the safety factor. This section enters the last part of BMS --BDU.

What is BDU

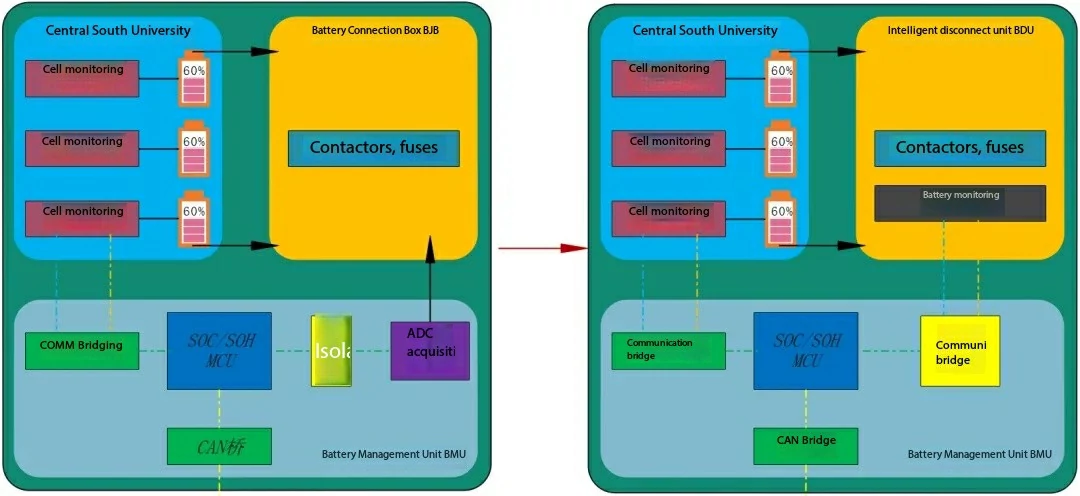

BDU is now a newly named name, also known as intelligent junction box BJB, compared with the traditional BJB, the traditional BJB only contains mechanical components, while the intelligent BJB will introduce active devices into the BJB to perform high voltage monitoring, current detection and insulation detection (traditionally performed by the BCU function). The difference between a smart BJB and a conventional BJB is the digital control of the contactor (relay) driver and the explosive fuse, which is used to interrupt the connection between the battery pack and the EV system during a collision.

Comparison of conventional and smart battery junction boxes (BJB)

As shown in Figure 4-1, the intelligent BJB architecture has several distinct advantages. It clearly distinguishes between high-voltage and low-voltage domains, and all high-voltage signals are measured directly in the BJB, thus making the BCU fully a low-voltage design. The battery pack monitor uses a proprietary Daisy link and supports discrete capacitor isolation, eliminating the need for expensive digital isolators. Daisy-chain communication also has the added advantage of not requiring any other components such as transceivers (such as CAN), nor additional MCUS to control and drive the communication protocol. Placing the battery pack monitor in or around the BJB gives immediate access to the high-voltage signal and eliminates the need to connect multiple long wires back to the BCU to measure current and perform shunt current detection.

Figure 4-1: Traditional BMS architecture compared to intelligent BJB architecture

1# : Eliminates a large number of connections between the BMU and BJB interfaces.

2# : Simplify hardware and MCU software development.

3# : Synchronous voltage and current measurement.

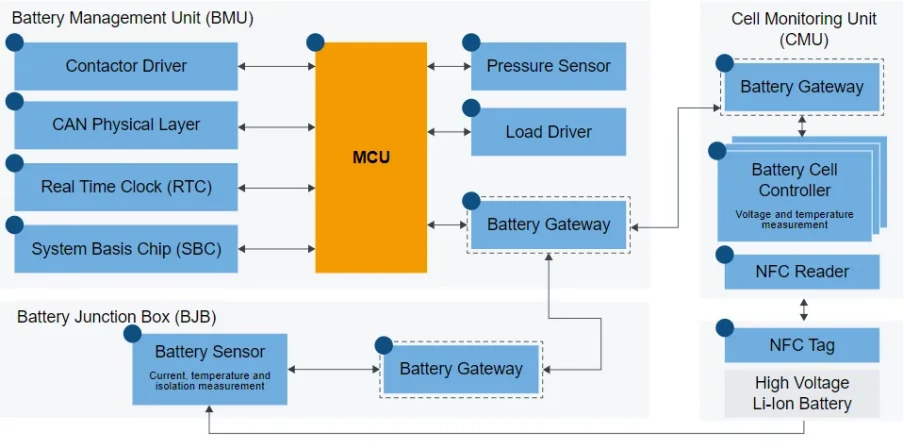

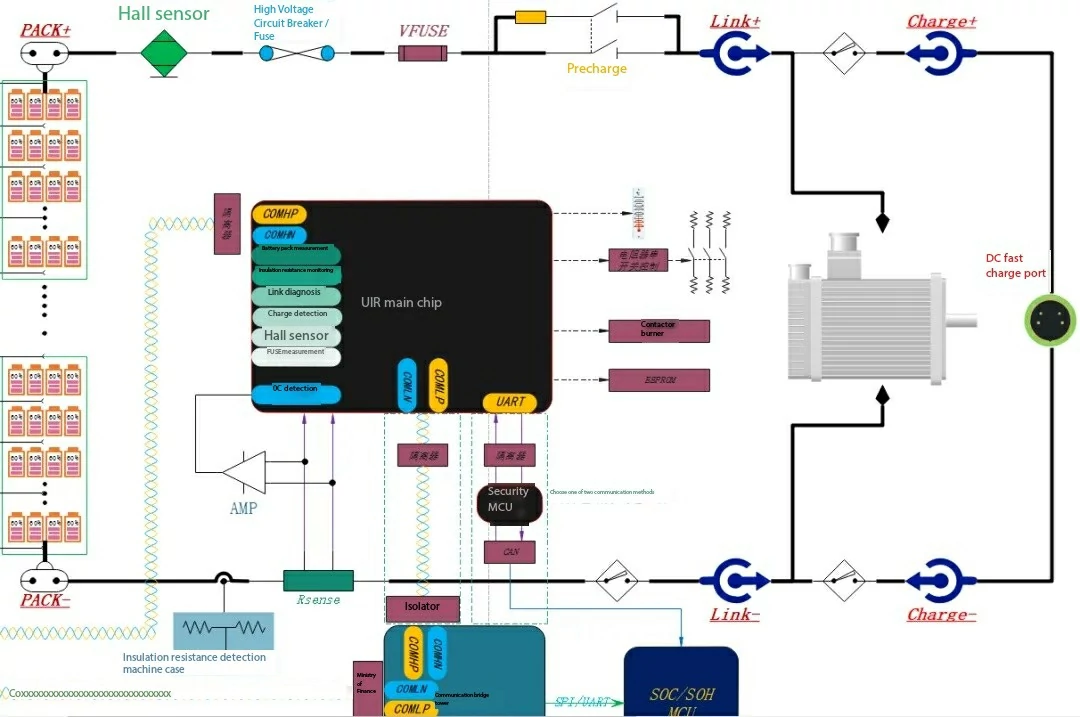

Figure 4-2: Complete BMS schematic

From Figure 4-2 and Figure 4-3, you can see that the BJB includes current (overcurrent protection), temperature, insulation detection, high side and low side relay driver control.

Figure 4-3: Part of the intelligent BJB

BDU link

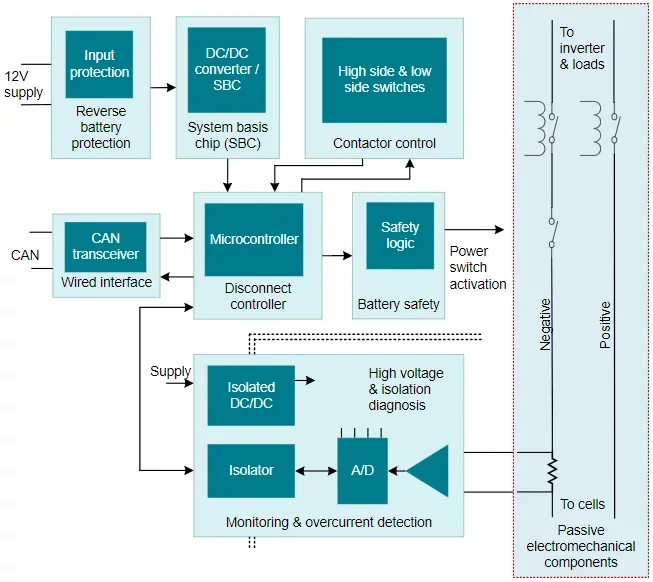

The smart BJB helps directly measure high voltages in the battery through voltage, current, and insulation resistance battery pack monitors. A typical battery pack monitor provides multiple voltage and current measurement channels to measure the voltage at both ends of the fuse and contactor, and to check the isolation voltage in the BJB. Figure 4-4 is a simplified system diagram.

Figure 4-4: Simplified BJB system block diagram

As can be seen from the figure, the main chip of UIR, as the core device of BDU, also replaces SOC/SOH MCU to complete PACK detection, insulation resistance detection, Link diagnosis (Link+/-), charge control/detection, Hall sensor reading, VFUSE control, relay driver control, dry current detection and other functions. Because the battery pack monitor can measure the battery pack current, overcurrent protection is included in the system.

Take UIR chip BQ79731-Q1 as an example, some battery pack monitors also have coulomb counting function for charge state calculation, BQ79731-Q1 realizes voltage and current synchronization function, can measure the battery pack current and voltage while measuring the battery cell voltage in CSU. All information captured through either Daisy chain communication interface is polled to the BCU. The BQ79731-Q1 features a Serial Peripheral Interface (SPI) controller channel that controls contactor drivers and explosive fuses, reducing the need for additional SPI resources on the BCU.

Battery packs use mechanical contactors controlled by battery pack monitors to connect or disconnect subsystems throughout the vehicle, it is important to prevent any potential failure of these contactors or contact high voltage connections, thereby protecting the driver from life-threatening injuries, mechanical high voltage contactors can be welded or damaged by arcing and pitting in the event of uncontrolled surge current.

CONCLUSION

Because the BDU is responsible for the trunk road, it is often designed to accurately detect current at the battery pack level and to use an advanced architecture with redundancy to deploy the system at a higher level of security.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

The cylindrical terminal of the battery pack

The cylindrical terminal of the battery pack Battery pack is...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.