Assembly flow process Preheating Preheating the component in preparation for...

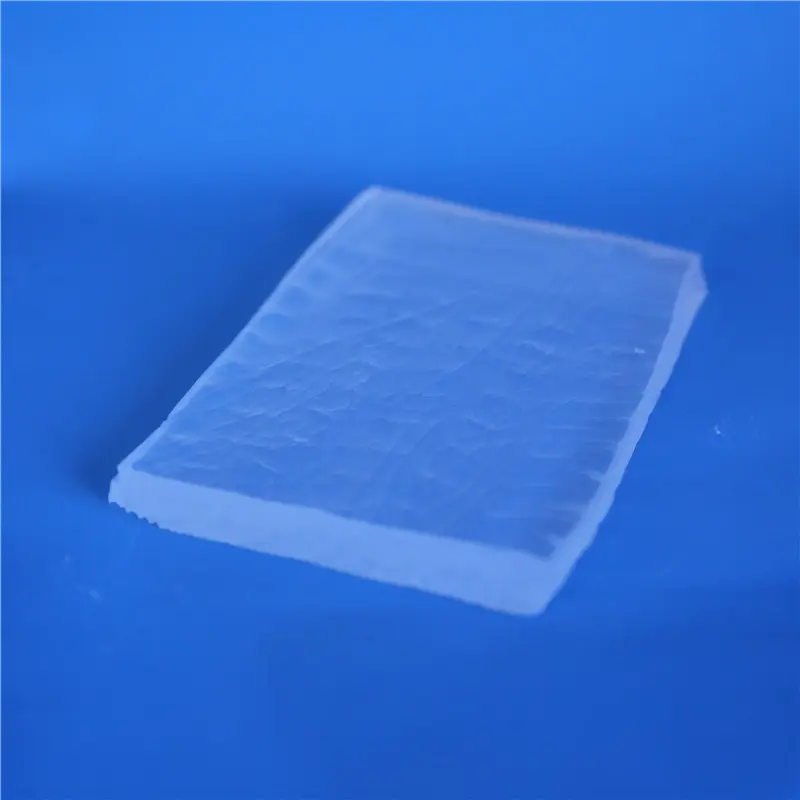

Battery sealing ring material

With the rapid development of science and technology, batteries, as an important part of modern energy, play a vital role in various devices. Whether it is a mobile phone, laptop computer, or electric vehicle, energy storage system, the performance and safety of the battery are very important. In this context, the battery sealing ring is a key component in the battery structure, and its material selection is particularly important. In this paper, the material of battery sealing ring and its importance will be introduced in detail.

Common battery sealing ring materials

Fluorine rubber

Fluorine rubber has become one of the preferred materials for battery sealing ring due to its excellent high temperature resistance, chemical corrosion resistance and oil resistance. It is able to maintain stable performance in extreme temperatures and harsh chemical environments, and is especially suitable for high energy density batteries such as lithium-ion batteries.

Silicone rubber (VMQ)

Silicone rubber has good high temperature resistance, low temperature resistance and weather resistance, and has excellent electrical insulation and physiological inertia. This makes it advantageous in battery applications that require a wide temperature range and good biocompatibility.

Nitrile rubber (NBR)

Nitrile rubber is known for its excellent oil and wear resistance, suitable for the environment containing organic solvents or oils. In some specific battery applications, such as lithium ion batteries containing carbonate solvents in the electrolyte, nitrile rubber can provide good sealing effect.

Polytetrafluoroethylene

Ptfe is widely used in battery sealing rings because of its extremely low friction coefficient, excellent chemical resistance and high temperature resistance. Its self-lubricating property can reduce the friction between the sealing ring and the battery housing, thus extending the service life of the battery.

the key factors of material selection

Operating temperature range: Ensure that the material maintains stable performance within the operating temperature range of the battery.

Chemical stability: The material should be resistant to corrosion by electrolytes and other chemicals.

Mechanical strength: the material should have sufficient tensile, compression and wear resistance.

Cost-benefit: Under the premise of meeting the performance requirements, try to select the material with lower cost.

Conclusion

In summary, the material selection of the battery sealing ring is of great significance to ensure the safety and performance of the battery. With the continuous progress of battery technology and the expansion of application fields, the requirements for sealing ring materials will also continue to improve in the future. Therefore, it is urgent to continuously develop new high-performance sealing ring materials to meet market demand.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Cycle life test of single cell battery

Cycle life test of single cell battery With the development...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.