Product testing Product testing is a key link to ensure...

Battery modular assembly

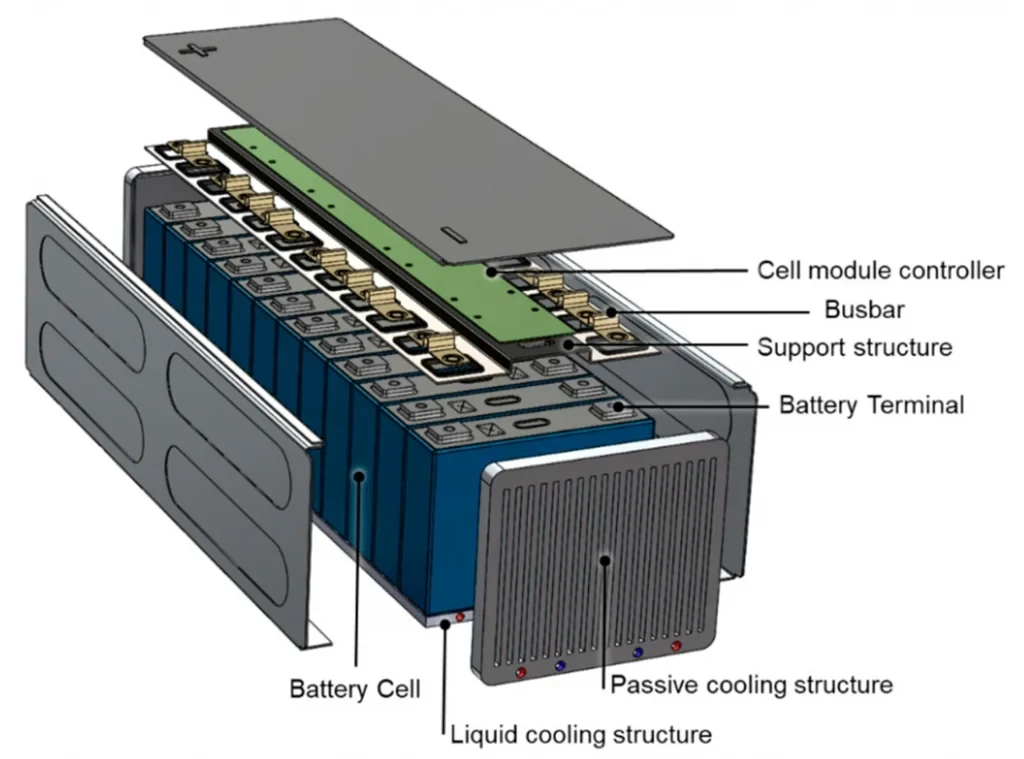

Battery modular assembly is the process of combining multiple single battery cells into a battery module, which is an important part of battery assembly. Through the modular design, multiple battery cells can be combined into a unit with independent functions according to a specific arrangement. The modular battery assembly not only improves the production efficiency, but also facilitates the later maintenance, disassembly and replacement. The main purpose of modular assembly is to ensure the structural stability of the battery pack, the consistency of the battery cell, and the safety and service performance of the battery pack.

Battery modular assembly

Battery modular assembly not only improves the production efficiency, but also facilitates the later maintenance and replacement by composing multiple battery monomers into modules. The modular design helps to ensure the safety and structural stability of the battery pack, while also meeting the flexible requirements of different markets and applications. By optimizing the thermal management system and integrating the protection circuit, the modular battery pack can improve performance while also ensuring longer service life and higher safety.

Main process

Battery cell arrangement and connection

Objective: To arrange multiple battery cells according to the design requirements of the battery pack to ensure that the voltage and capacity of each cell in the battery pack match. Process: According to the specification and design requirements of the battery pack, the selected battery cells are arranged horizontally or vertically, and the battery cells are connected into a module through conductive connecting pieces, soldering or tin-plated pins. At this point, make sure that the connection can effectively transfer current and has sufficient mechanical strength.

Module fixed and support structure design

Objective: To ensure that the battery module will not be loosened or damaged due to vibration or external force during use.

Process: The battery cells are held together using a metal frame or a strong support structure to prevent physical damage or displacement of the battery during use. The fixed structure needs to take into account the thermal expansion and cooling requirements of the battery to avoid overheating or uneven temperature of the battery.

Thermal management and insulation design

Objective: To effectively manage the heat generated by the battery in the process of charging and discharging, and ensure the temperature stability of the battery pack under different working conditions. Process: Heat insulation materials or heat sinks are added to the battery module to ensure that the heat of the battery pack can be effectively distributed through the design of reasonable ventilation holes and cooling systems. An efficient thermal management system helps to improve the safety, stability and service life of the battery pack.

Protection circuit integration

Objective: Through the battery management System (BMS) integrated protection circuit, to ensure that the battery module will not occur in the charging and discharging process of over-charge, over-discharge, short circuit and other safety problems.

Process: The battery management system (BMS) and protection circuit are installed in the battery module to monitor the voltage, current, temperature and other parameters of the battery module, and deal with abnormal situations in time to avoid battery damage or accidents caused by protection failure.

low-speed car batteries

Low-speed vehicle battery is a kind of battery designed for low-speed electric vehicles, which has the characteristics of clean, environmental protection, high efficiency and economy, and is widely used in electric golf carts, low-speed electric vehicles (LSV), mobile vendors, campus transportation, cargo trucks and so on

Extended reading

Product packaging and delivery

Product packaging and delivery The packaging and delivery of battery...

Product information expansion

Product information expansion Understanding low-speed vehicle battery product information is...

Product composition

Low-speed lithium battery product composition Understanding the product composition of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.