Roll pressure After coating and drying, the stripping high strength...

Battery Management System (BMS)

Battery Management System (BMS) is an integral part of modern battery packs, especially lithium battery packs. Its main task is to ensure the safe, efficient and long-life operation of the battery. This paper will introduce the working principle, function, composition, type and system test of BMS in detail.

The working principle of the BMS can be divided into three protection circuits, designed to ensure the safety and stability of the battery pack in different working states.

Primary protection circuit: mainly monitors the basic parameters of the battery, such as voltage, temperature and current.

Secondary protection circuit: When the primary protection fails to respond in time or when multiple cells are abnormal, the secondary protection circuit will intervene. It may prevent a more serious condition by disconnecting the battery or load.

Tertiary protection circuit: This is the final protection layer, which is used to intervene when secondary protection does not work. Measures at this level often include cutting off the power to the entire battery system to ensure the safety of equipment and people.

Perception and measurement

BMS senses the state of the battery by monitoring key parameters such as voltage, current and temperature in real time through a variety of sensors. The accurate collection of these data is the basis for judging the operating status of the battery.

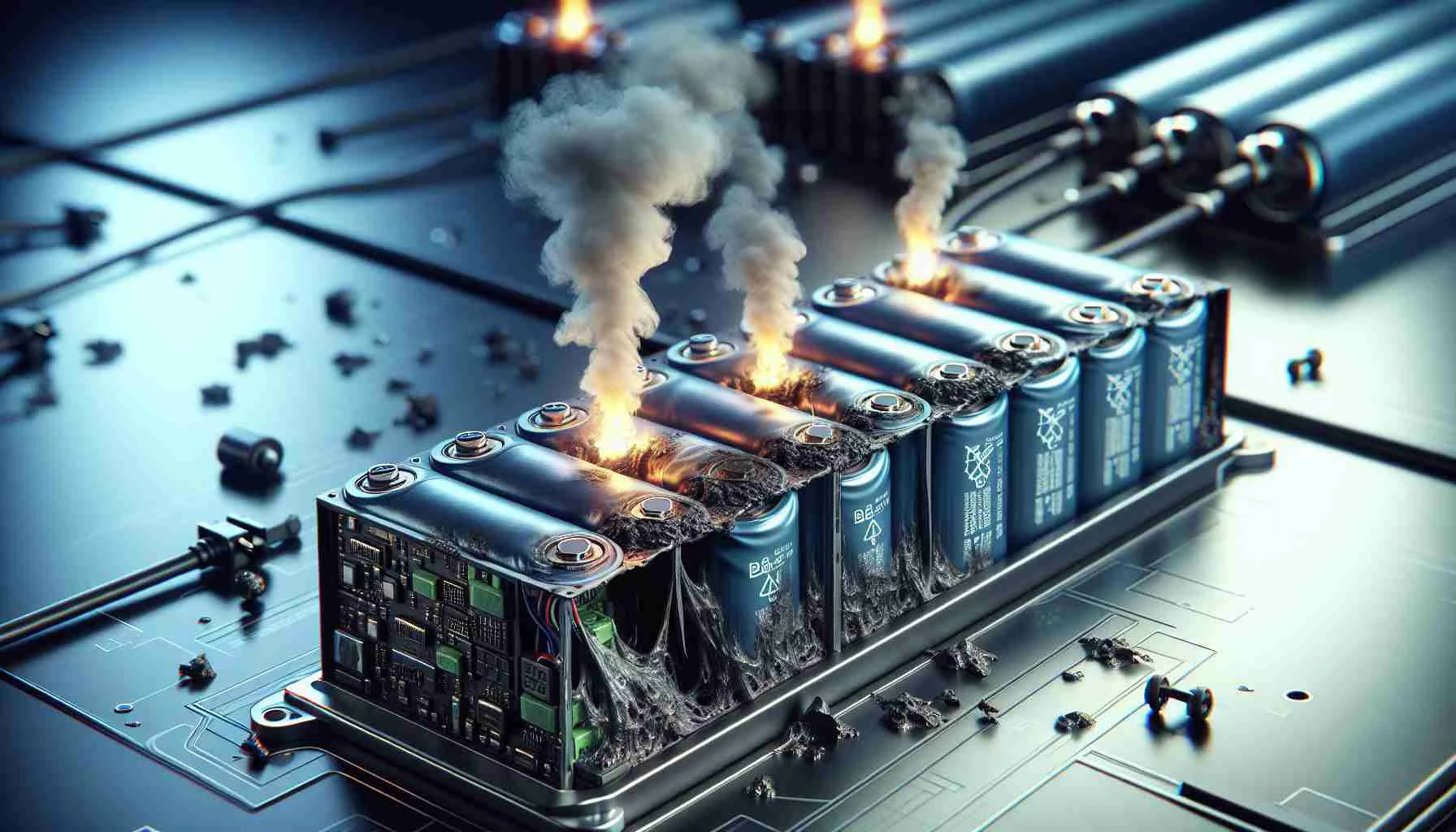

Alarm and Protection

Once abnormal conditions are detected (such as high or low battery voltage, abnormal temperature, etc.), the BMS will immediately issue an alarm and activate a protection mechanism to prevent battery damage or accidents.

Balanced management

The BMS is responsible for the balanced charging of each cell in the battery pack, maintaining the overall performance of the battery pack and extending the service life by active or passive balancing, and ensuring the consistency of the charging and discharging ability of each cell battery.

Communication and positioning

BMS transmits the status information of the battery to external devices such as chargers and vehicle control systems through CAN bus, RS-485 and other communication protocols. This capability allows the battery pack to be monitored and scheduled remotely, while also optimizing the charging and discharging process.

The components of BMS mainly include the following categories:

Control Unit Subsystem (CUS) : CUS is the core part of the BMS, responsible for data processing and decision making.

Battery Cell Unit (BCU) : The BCU monitors the voltage and temperature of each battery to ensure the health status of the battery.

Battery Disconnect Unit (BDU) : The main function of the BDU is to manage the connection and disconnection of the battery pack according to the instructions of the CUS.

BMS can be classified according to different criteria, mainly including:

According to structure classification, it can be divided into centralized BMS and distributed BMS.

It can be divided into passive balanced BMS and active balanced BMS according to function classification.

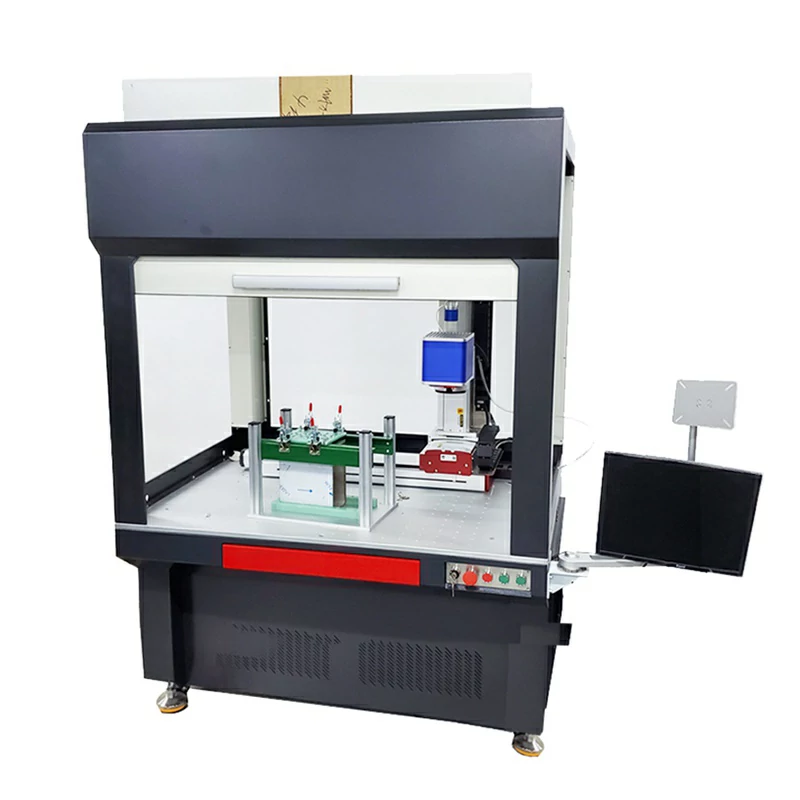

System test of BMS

The testing of BMS is a key step to ensure its reliability and security, which mainly includes the following aspects:

Functional test:

Verify that the basic functions of the BMS are normal, including data collection, condition monitoring, balancing, alarm, and communication.

Performance test:

The performance of the BMS is tested under various operating conditions (such as different temperatures, charge and discharge rates) to ensure that it can work properly under extreme conditions.

Security test:

Simulate various battery faults (such as short circuit, overvoltage, etc.) to test to see whether the protection mechanism of the BMS is effective.

Reliability test:

Verify the long-term operation of the BMS to ensure that it can provide stable and durable performance in actual use.

Communication test:

Verify that the communication between the BMS and external devices is normal to ensure accurate transmission and timely response of data information.

Conclusion

Battery management system (BMS) plays an important role in battery safety management, charge and discharge control, performance optimization and so on. Through the sound working principle, function and structure, combined with different types of design and system testing, BMS ensures the safety and efficiency of battery packs in a variety of application scenarios. With the advancement of science and technology, BMS technology will continue to develop, providing more powerful support for the wide application of batteries.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

Operating temperature range of the battery pack

Operating temperature range of the battery pack Battery packs play...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.