Dry and store Dry storage in the production process of...

Bake the polar slices

Lithium battery electrode baking is an important part of the lithium battery manufacturing process, the main purpose is to remove the water and solvent in the electrode plate to ensure the electrochemical performance and safety of the battery. The following is a detailed introduction to pole baking:

Anode baking process:

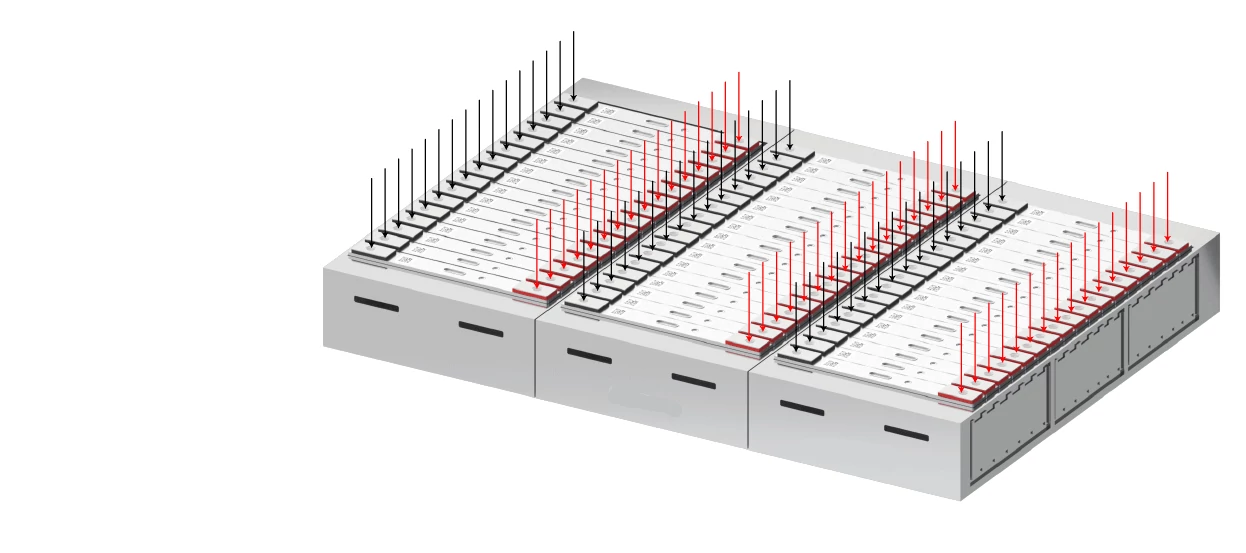

The anode baking process can be divided into four stages: preheating stage, heating stage, constant drying rate stage and deceleration stage.

In the preheating stage, hot air quickly passes over the surface of the coated stock, heating the foil and the stock, and causing the solvent to evaporate on the surface of the stock.

In the constant drying rate stage, a large amount of solvent in the coating paste evaporates, and the solvent reaches the surface of the coating and accumulates.

The slow down stage is controlled by the solvent migration rate, which is controlled by the distribution of particles and gaps in the semi-dry coating layer.

Factors that affect baking:

Hot air temperature: Reasonable control of temperature and wind speed can effectively improve the performance consistency of a single battery. When the drying temperature is lower, the distribution of binder is more uniform, and the bonding between the collector fluid and the active material is more firm. Hot air speed: the hot air flow speed is too large, resulting in uneven coating, low speed and large flux is more conducive to the drying quality of pole sheet.

Drying technology:

Infrared drying: can remove the capillary water and surface residual water in the electrode coating, suitable for high energy electrode coating with large thickness. The drying process is simple, the heat is concentrated and the drying speed is fast, but it may cause the second agglomeration of the binder and affect the electrochemical performance.

Microwave drying: Through microwave dielectric heating to promote the removal of water in the electrode. When the microwave is used for volumetric heating, the free water inside the pole plate first vaporizes during drying, forming a higher evaporation pressure gradient and accelerating the internal water migration. Microwave mixed drying can greatly improve the drying efficiency, and the damage to the coating is small, but it is easy to cause pole plate bulge and fried chips.

Determination of baking temperature: The method to determine the optimal baking temperature for coating includes setting multiple baking temperature parameters, coating and baking multiple positive plates, and then performing peel strength testing and element content detection to determine the optimal baking temperature.

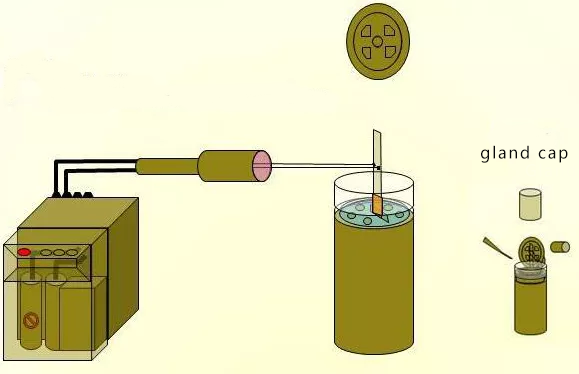

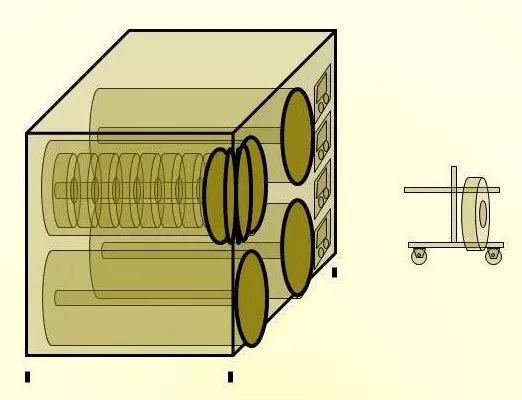

Vacuum drying process: In order to improve the drying efficiency of the pole sheet and product quality, a vacuum drying oven is used. By adding a movable vacuum chamber in the ordinary oven, the pole sheet or battery is put into the vacuum chamber for vacuum baking, which ensures a higher vacuum degree and product consistency.

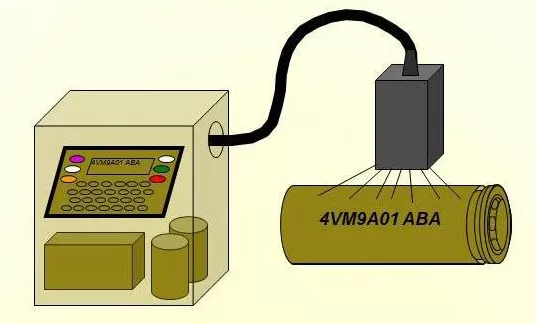

Induction heating drying method: This is a new heating drying method of pole sheet, which is completed by loading induction heating coils with medium frequency or high frequency AC. This heating method belongs to the self-induction heating of metal materials, does not need to heat the circulating air, has high thermal efficiency, and greatly reduces the energy consumption of the heating and cooling process of a large number of circulating air.

CONCLUSION

In summary, lithium battery electrode baking is a complex process, involving multiple stages and a variety of technologies, the purpose of which is to ensure the safety and performance of the battery.

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.