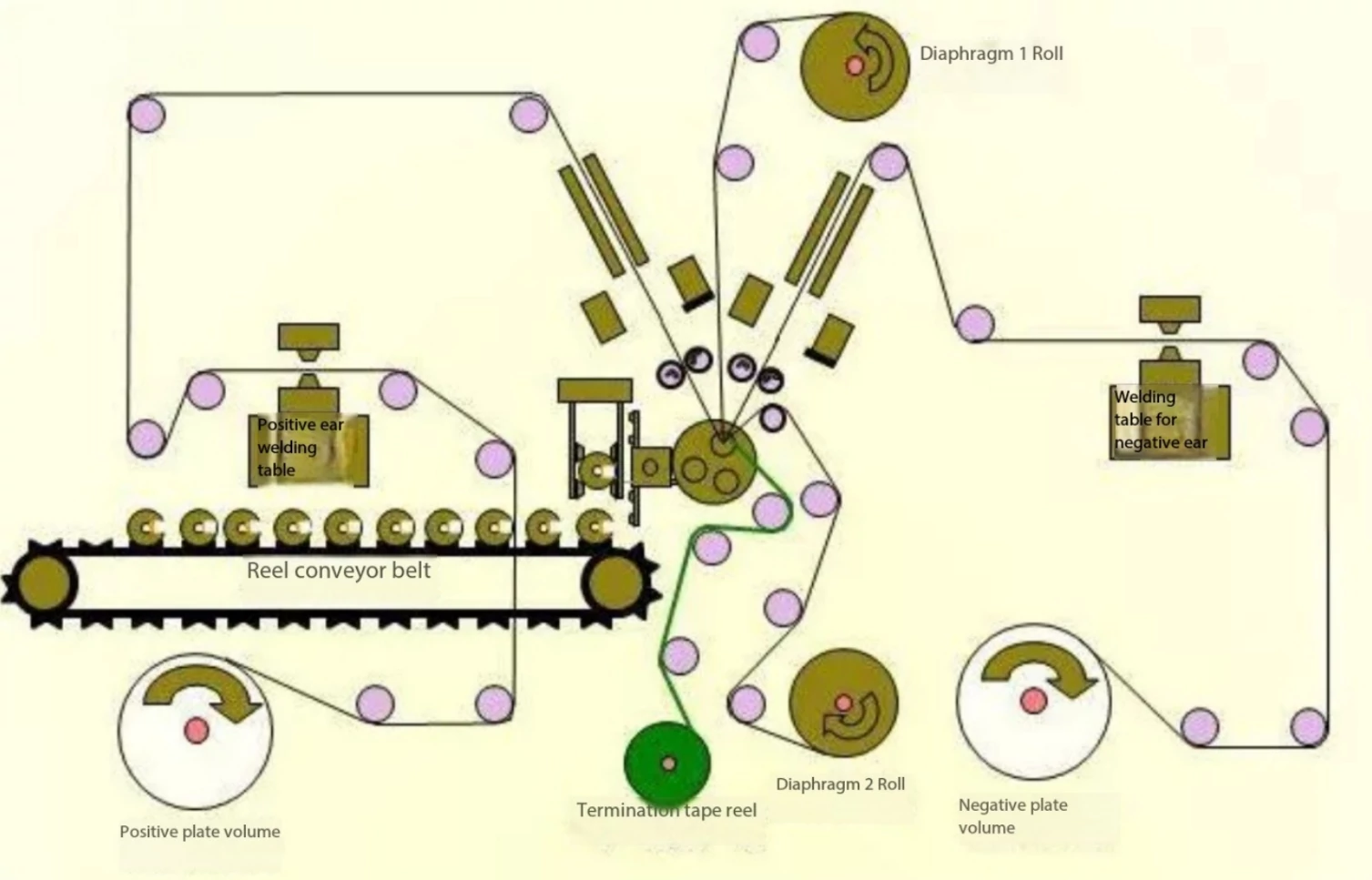

Weld cap A key step in the lithium battery production...

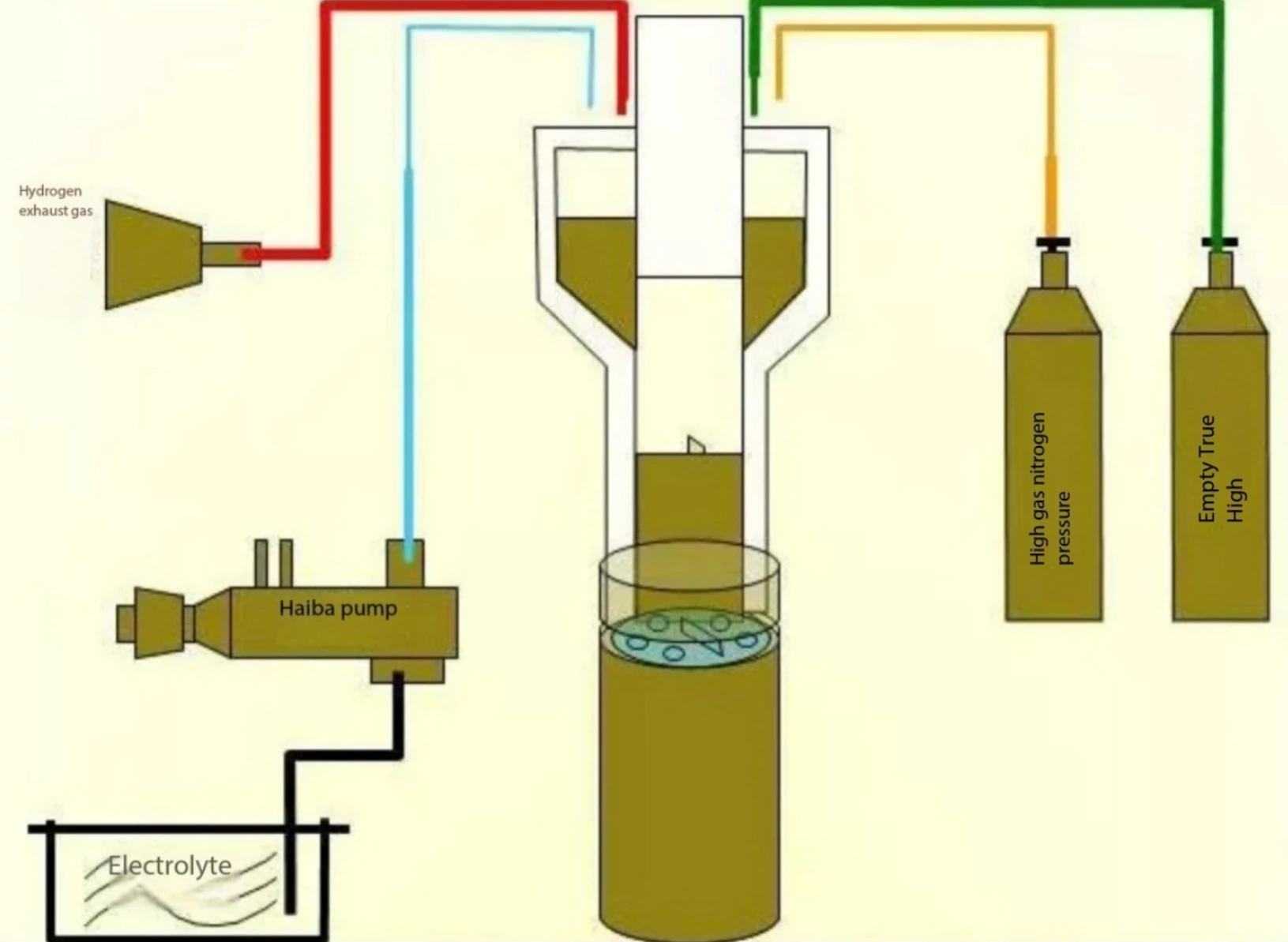

bake

The main purpose of the battery baking process is to remove the internal and external moisture of the battery to improve the stability and reliability of the battery. In addition, baking also helps in welding flow, ensuring the quality and reliability of the welding points, as well as simulating the aging process of the battery, accelerating the aging of the battery to verify the performance and life of the battery.

Specific process steps:

Temperature setting: According to the battery type and requirements, set the appropriate baking temperature. Different battery materials and structures may require different baking temperatures.

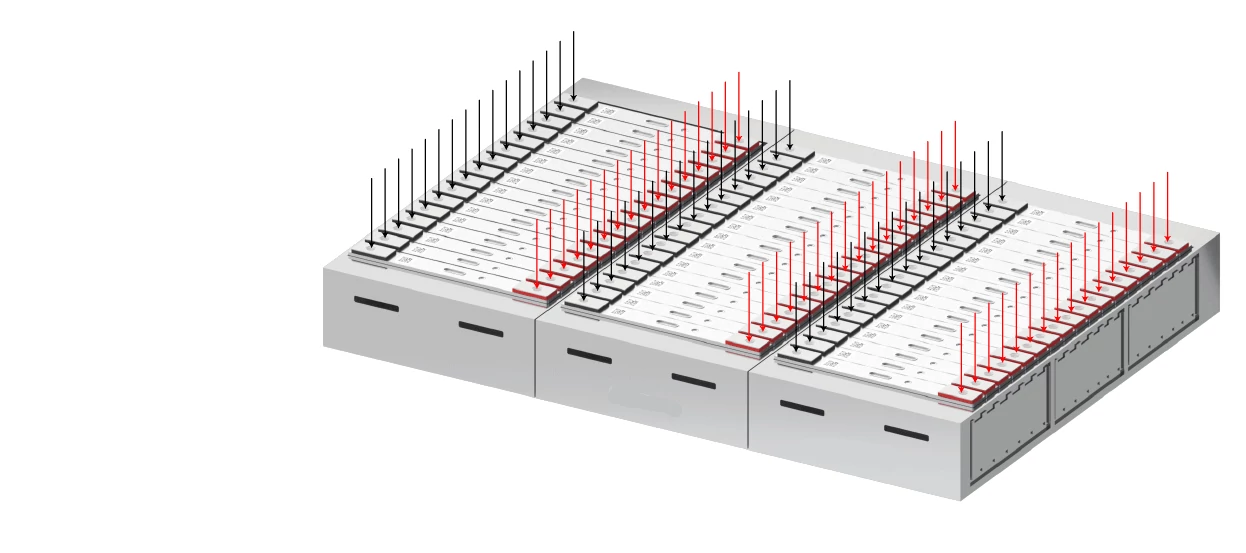

Heating and preheating: Put the battery cell or battery pack into the baking equipment for heating and preheating, so that the internal temperature of the battery gradually rises. The preheating process helps the water inside the battery gradually evaporate.

Stable baking: When the internal temperature of the battery reaches the set temperature, keep it for a certain time to make the water inside the battery evaporate and welding flow completely. This time depends on the type and requirements of the battery, and usually takes several hours to tens of hours.

Cooling shutdown: Stop heating, and take out the battery cell or battery pack for cooling, so that its temperature gradually decreases. The cooling process not only helps protect the battery from heat damage, but also helps stabilize the battery's performance.

Inspection and verification: The appearance inspection and electrical performance test of the baked battery are carried out to verify the baking effect. These tests can ensure that the battery meets the quality requirements and has good performance.

CONCLUSION

Through the above steps and control elements, the baking process of the lithium battery ensures the drying and cleaning of the battery components, which provides an important guarantee for the performance and safety of the battery.

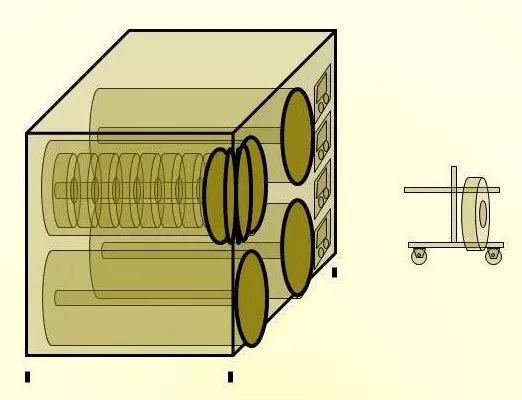

EPS BATTERY SERIES

The centralized power supply for fire emergency lighting is a kind of backup power supply equipment, which provides power guarantee for emergency lighting equipment to ensure that the on-site lighting equipment can operate normally in emergency situations such as fire. Provide a long-term backup power supply to meet the needs of the emergency lighting system.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.