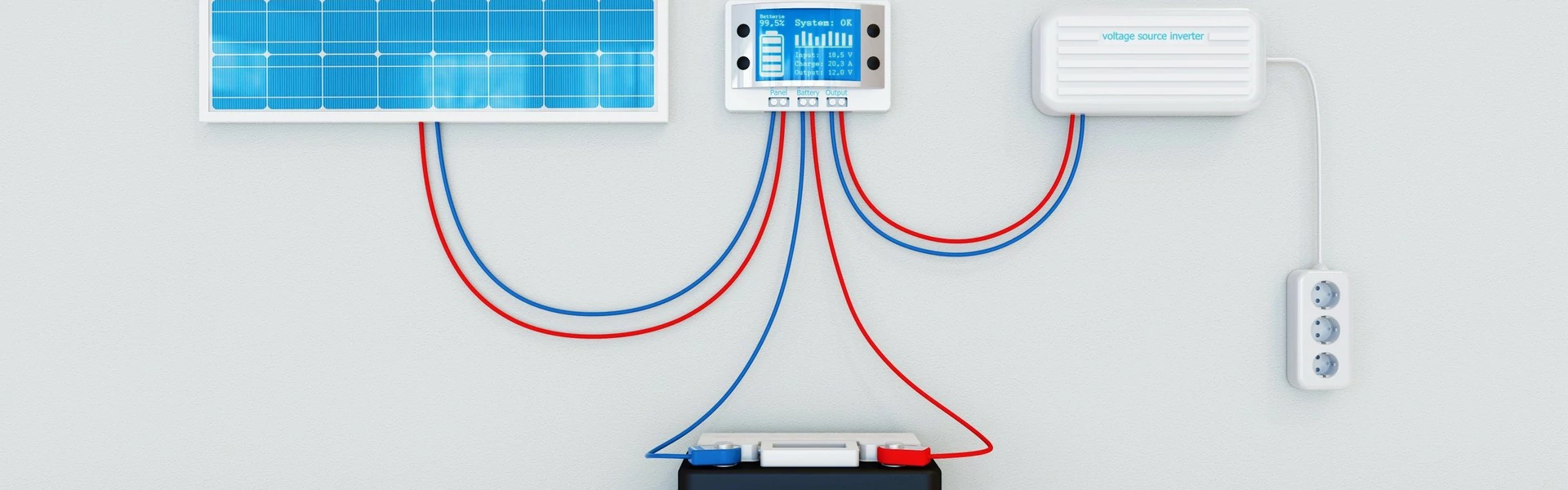

A highly integrated backup power solution for solar home energy...

Backplane

The solar module, as the core equipment that converts sunlight into electricity, is composed of several parts, of which the backplane, as an important part, plays the role of protection, support and insulation. The quality of the backplane directly affects the performance, durability and safety of the solar module. This paper will introduce the backplane in solar module in detail, including its function, material, manufacturing process and development trend.

the function of the backplane

The backplane of the solar module is usually located on the back of the photovoltaic cell sheet, and its main functions include:

Protection: The backplane protects the battery from the external environment, such as moisture, dust and mechanical impact. It can prevent moisture infiltration and avoid the failure of the battery due to moisture.

Insulation function: The backplane provides electrical insulation to prevent current leakage and ensure the safety of components. Effective insulation reduces the risk of electrical accidents and protects users and equipment.

Structural support: The backplane provides structural support for the components, ensuring overall stability and durability. It helps to disperse the load caused by environmental factors such as wind pressure and snow pressure.

Thermal management: The material and design of the backplane also affects the thermal performance of the component, helping to control the operating temperature, thereby increasing the efficiency and service life of the battery.

the material of the backplane

Polymer material

Examples include polyvinyl chloride (PVC), polyester (PET) and polystyrene (PS).

Advantages: These materials are light weight, low cost, and have good water resistance and insulation. Commonly used in low-end solar modules.

Composite material

For example, a composite back plate made of plastic and aluminum or other materials.

Advantages: It has excellent mechanical strength and weather resistance, and can maintain stability under extreme climatic conditions.

Glass back

Features: Compared to traditional plastic backboards, glass backboards provide higher durability and security against UV rays, chemical corrosion and mechanical impact.

Advantages: The additional layer of clear glass can improve the optical performance of the component, but also increase the weight of the component.

Manufacturing process

The manufacturing process of a backplane involves several steps, usually including:

Material preparation: Select a suitable material, usually a polymer with good properties in providing water resistance, insulation and weather resistance.

Coating treatment: The backplane material is surface-coated to enhance its UV protection and water resistance.

Cutting and forming: The material is cut to the size of the design and molded according to the requirements of the component.

Bonding and packaging: The backplane is bonded to the photovoltaic cells, usually using a special glue or adhesive to ensure tightness.

Quality inspection: Strict quality inspection is carried out in every link of production to ensure that the backplane meets the relevant standards.

the market trends and challenges of backboard

With the rapid development of the solar market, the technology and materials of the backplane are also constantly evolving. Here are some of the market trends and challenges in recent years:

Application of high performance materials: With the increasing demand for module efficiency and durability, more and more high performance materials, such as composite materials and glass backplanes, are being used in high-end solar modules.

Environmental trends: Many manufacturers are starting to focus on the recyclability of backboard materials, developing more environmentally friendly materials and production processes to reduce environmental impact.

Durability and long-term performance: Backplanes need to show long-term stability in different climatic conditions, and manufacturers are constantly making technological innovations to improve the weather resistance and service life of their products.

Cost and benefit: Although the use of high-performance materials improves the performance of components, it also brings an increase in cost. How to find the balance between performance and cost is an important challenge for enterprises.

Summary

Although the backplane in the solar module is in a relatively hidden position, its importance cannot be ignored. As a key component of protection, insulation and support, backplanes directly affect the efficiency and safety of solar cells. With the advancement of technology and changes in market development, the materials and design of backplanes are also increasingly innovative. In the future, the development of backplanes will continue to contribute to the sustainable development of the solar energy industry and promote the wider application of clean energy.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.