valve-controlled relief valves In industrial automation and all kinds of...

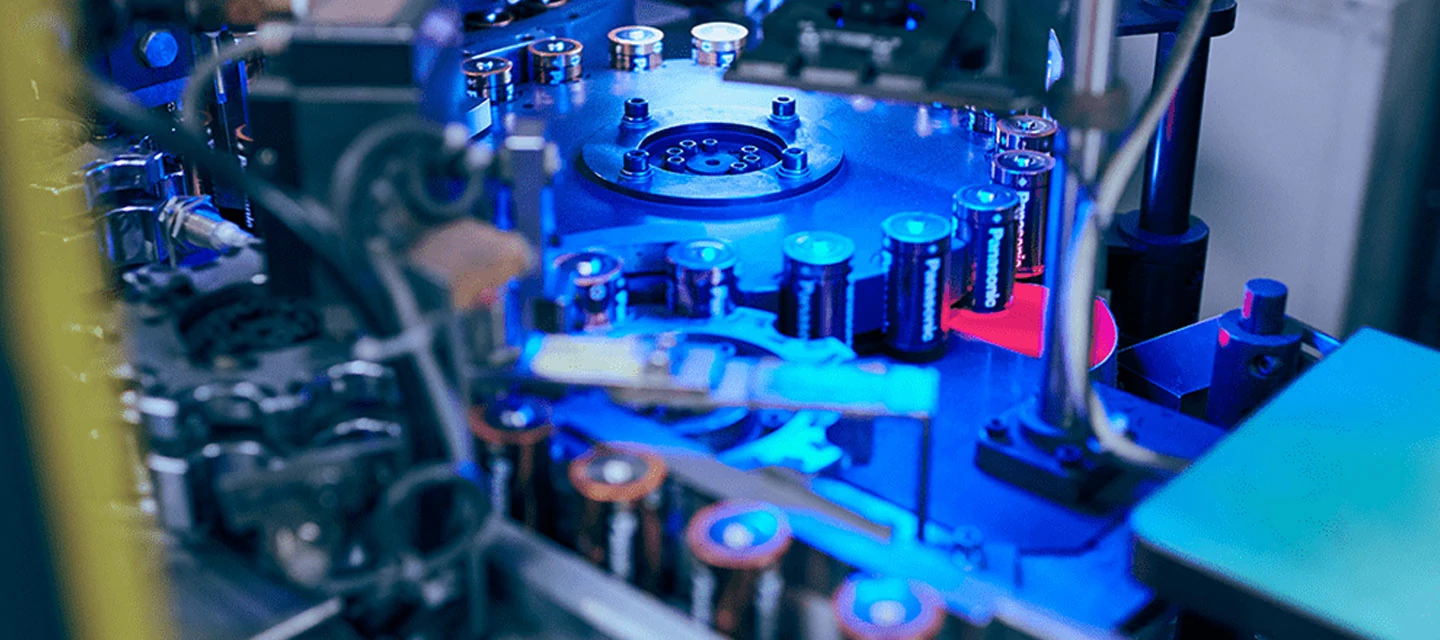

Assembly flow

process

Preheating

Preheating the component in preparation for subsequent hot pressing steps. The use of baking technology, baking and then heat pressure, increase the compaction effect.

The preheated component is hot pressed to form the desired shape or connection.

X-ray Inspection

The equipment uses X-ray to transmit the inside of the product, and images it, and detects the internal structure. By detecting whether the positive and negative electrodes are misplaced, the isolation state is ensured, which plays a crucial role in the safety of the later market.

X-Ray nondestructive testing equipment sends X-rays through the X-Ray generator to penetrate the inside of the battery, and X-ray imaging and photography are received by the line array detector. The image is processed by the detection software, and the alignment of the positive electrode film, negative electrode film and diaphragm is automatically measured and judged to determine good and defective products.

If the X-ray test result is NG (not acceptable), Rework is performed.

Ultrasonic welding of components to realize the connection between components.

Weld the connector and top cover together using laser welding technology.

The soldered component is encapsulated with Mylar (a Mylar film).

Preliminary Soldering before Housing: The component is prewelded before housing.

The component is prewelded before housing.

Soldering the top cover to the assembly.

First Oxygen Test

Perform the first helium test to ensure the tightness of the assembly.

Helium filled vacuum, high temperature heating, nitrogen filled is to replace the air, the role of breaking the vacuum, making better thermal conductivity, better water evaporation.

The battery is dry leak detection, through the test of the battery vacuum and helium filling, the application of vacuum box method helium mass spectrometry gas tightness detection, through the device to determine the inspection of qualified and unqualified workpiece.

If a helium test is OK, proceed to the next step.

If the result is NG, rework is performed.

Sealing Pin Welding

Seal pin welding is performed on the components to ensure tightness.

Second Ammonia Test

A second helium test is performed to further ensure the tightness of the assembly.

If the result of the secondary helium test is OK, the process ends. If the result is NG, rework is performed.

End

The end of the process, indicating that the component has passed all inspection and welding steps and is assembled.

The complete process from preheating to final assembly is shown, including multiple inspection and welding steps, as well as a rework process in case of nonconformity.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

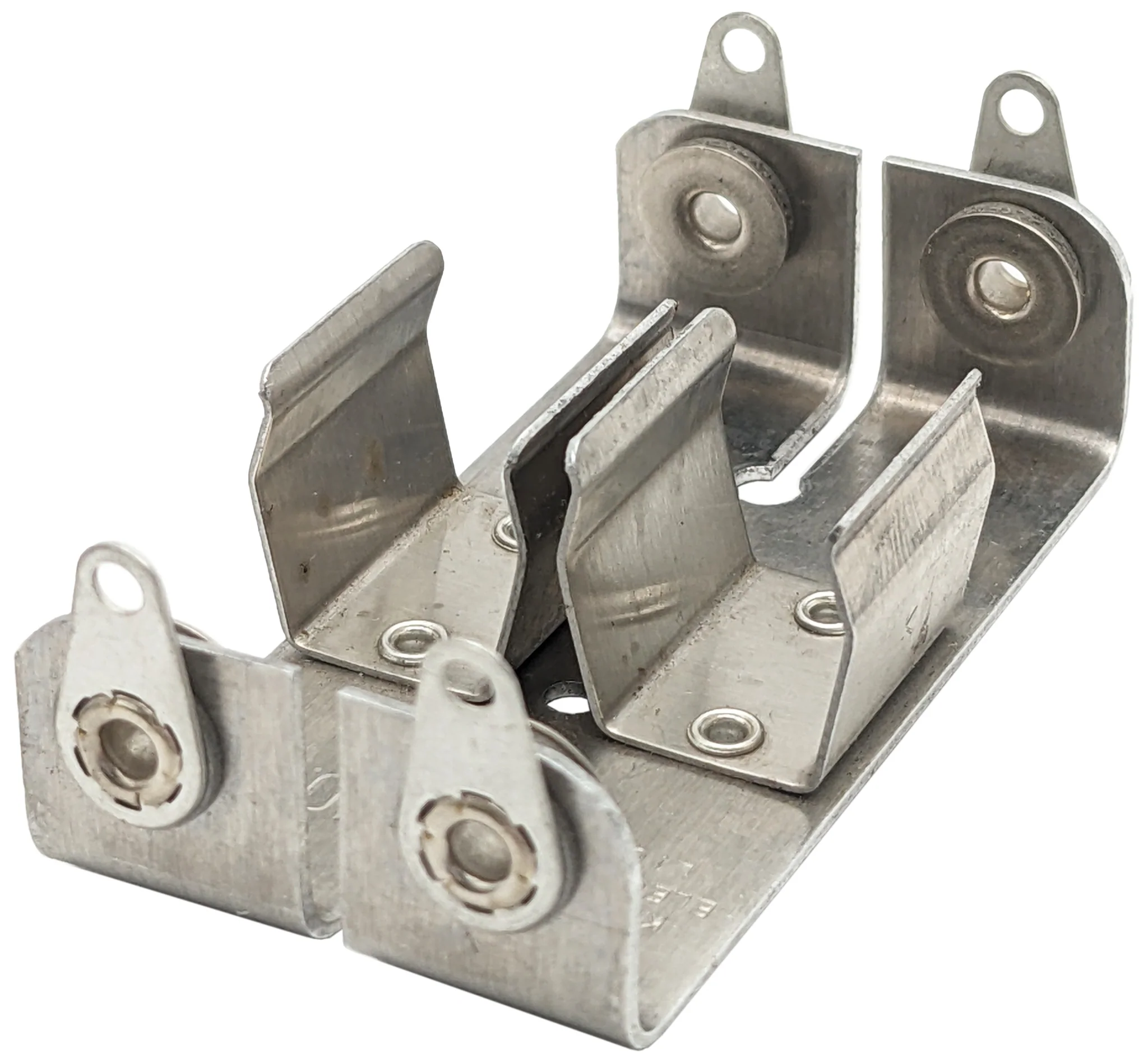

Introduction of battery pack components

Introduction of battery pack components A battery pack consists of...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.