Introduction to the positive cap of lithium iron phosphate monomer...

Application and advantages of silicate materials in lithium battery separator

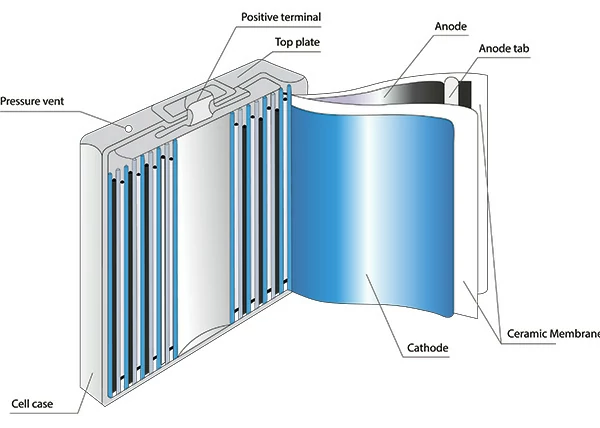

Lithium-ion batteries are widely used in electronic devices, electric vehicles and energy storage systems due to their high energy density and excellent cycling performance. Among them, the battery diaphragm, as a key functional material, plays an important role in isolating the positive and negative electrodes and allowing lithium ions to pass through. In recent years, many researchers have discussed the application of new materials in battery separators, and silicate materials have gradually attracted attention. This article will introduce why silicate materials can be used as lithium battery separators, and discuss its advantages and prospects.

Basic characteristics of silicate materials

Silicate material is a kind of inorganic compound composed of silica-oxygen tetrahedron, which widely exists in nature. Its known features include:

Chemical stability: Silicate materials usually have excellent chemical stability, good tolerance to electrolytes, and are able to maintain their properties over long periods of use.

High thermal stability: Silicate materials can maintain thermal stability at higher temperatures, reducing the risk of thermal runaway in high temperature environments.

Good mechanical strength: silicate materials have high mechanical strength and can withstand certain external pressure and impact.

The advantages of silicate as a lithium battery diaphragm

Good thermal stability

The silicate material has a strong ability to maintain the structure at high temperature, which can effectively prevent the decomposition and thermal runaway of the battery in the case of overheating. This feature plays a crucial role in the safety of lithium batteries and is a key factor in preventing fire and explosion.

Low cost and environmental friendliness

Compared with some synthetic polymer materials, the production of silicate materials is relatively simple and low cost. At the same time, as an inorganic material, it has excellent environmental friendliness and does not produce harmful volatile organic compounds (VOCs).

Excellent electrical insulation

The silicate material shows good electrical insulation in the case of no external electric field, which can effectively prevent the internal short circuit of the battery, thereby enhancing the safety of the battery. Its insulation does not decrease even at higher operating temperatures.

Mechanical strength and corrosion resistance

The silicate diaphragm exhibits good tear resistance and puncture resistance when subjected to mechanical stress, which makes the battery not easy to be damaged during use. In addition, the resistance of the silicate material to the reaction of the electrolyte ensures the electrochemical stability.

Excellent ionic conductivity

The silicate material conducts electricity effectively in its hydrated state, which allows it to allow lithium ions to pass through during battery operation. At the same time, the porous characteristics of silicate allow it to adjust the porosity to achieve good ion conduction ability, thereby improving the charging and discharging efficiency of the battery.

Application prospect of silicate diaphragm

With the development of technology and the improvement of battery energy density requirements, the research of silicate separator is continuously deepening. Researchers are exploring different types of silicate materials and their complexes to further improve battery performance. For example, the development of composite silicate materials (in combination with polymers or other inorganic materials) can enhance ionic conductivity and mechanical strength, thereby improving the overall performance of the diaphragm.

In addition, due to the rapid development of the lithium battery market, there will be an increasing demand for diaphragm materials for applications such as energy storage and electric vehicles. Silicate material will occupy an important position in the future lithium battery market because of its advantages of environmental protection, economy and high performance.

conclusion

Silicate materials have a variety of superior properties as lithium-ion battery separators, including good ionic conductivity, thermal stability and mechanical strength. With the continuous emergence of new materials and application expansion, silicate diaphragm will provide a good solution for improving the safety, stability and economy of lithium batteries. In the future, silicate materials will play an important role in lithium batteries and other energy storage technologies, helping to promote the development and popularization of renewable energy.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

The process flow of vertical section of lithium ion battery pack

The process flow of vertical section of lithium ion battery...

Method for measuring the thickness and porosity of diaphragm and electrode materials

Method for measuring the thickness and porosity of diaphragm and...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.