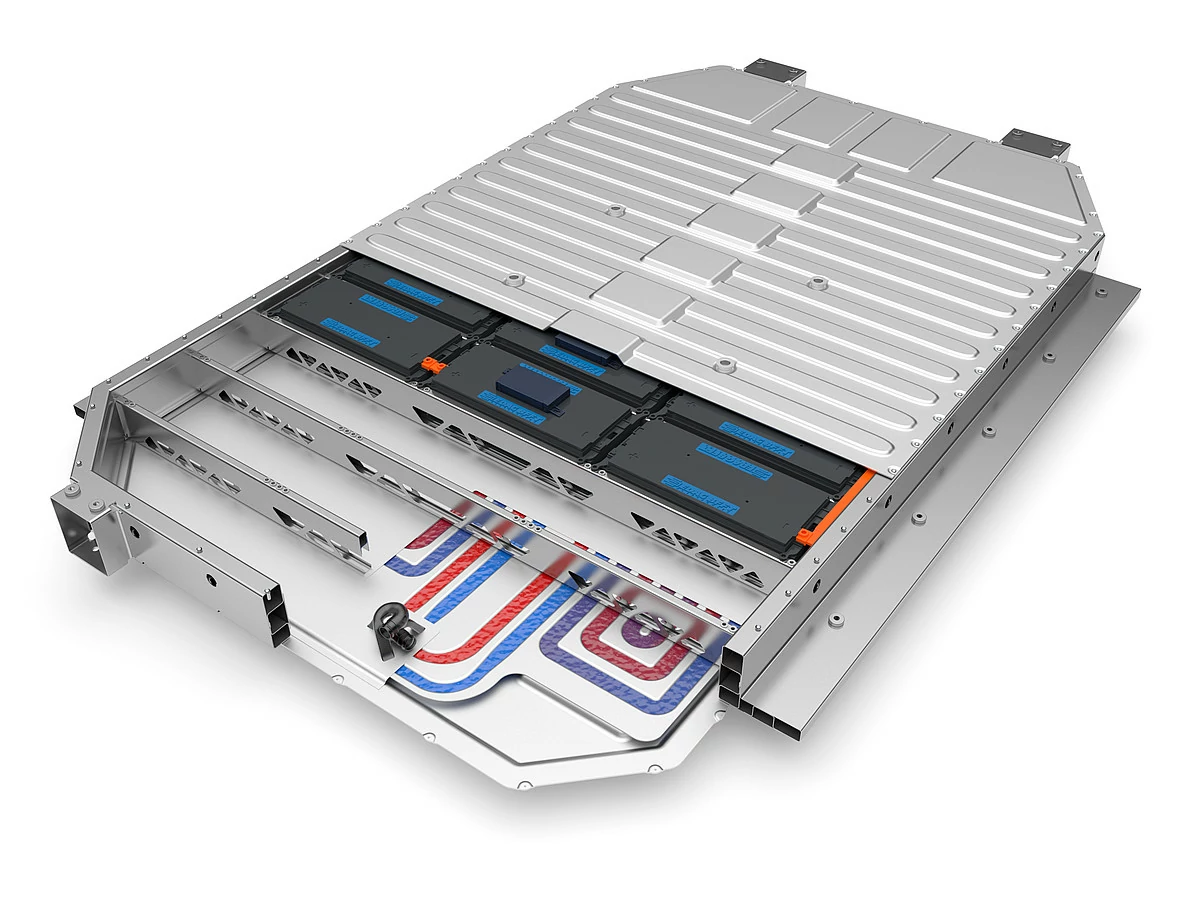

Introduction of the body material of the battery pack mechanical...

Application and advantages of inorganic materials in lithium battery separator

Lithium-ion batteries are widely used in electric vehicles, mobile electronic devices, and energy storage systems due to their high energy density and long cycle life, while the performance and safety of batteries largely depend on their separator materials. In recent years, inorganic materials have attracted more and more attention from researchers and manufacturers due to their superior physical and chemical properties. This paper will discuss the advantages and application prospects of inorganic materials as lithium battery separators.

Definition and characteristics of inorganic materials

Inorganic materials are compounds that do not contain carbon-hydrogen bonds and usually include metal oxides, nitrides, silicates, and other mineral materials. Compared with traditional organic polymer materials, inorganic materials show significant advantages in terms of thermal stability, chemical stability and mechanical strength.

The superiority of inorganic materials as lithium battery separator

Good chemical stability

Inorganic materials have good chemical stability to the electrolyte, which can reduce the reaction with the electrolyte and reduce the occurrence of side reactions. For example, compared with polymer separators, some inorganic separators can effectively prevent the deposition of lithium metal and improve the overall performance and cycle stability of lithium batteries. This is crucial for the development of batteries with high energy density.

High mechanical strength

Inorganic materials usually have excellent mechanical strength and toughness, making them more resistant to tearing and puncturing when subjected to external pressure or impact. This feature is very important for the long-term stability and safety of the battery, especially in high-power applications such as electric vehicles, which ensures the safety of the battery.

Lower resistance

Some inorganic materials, such as solid electrolyte materials, have low ionization resistance and can improve the conductivity of lithium ions. This will directly affect the charging and discharging efficiency of lithium batteries. For example, inorganic materials such as lithium oxide (Li2O) and lithium fluoride (LiF) currently show good performance in solid diaphragm research and can adequately meet high power requirements.

Excellent thermal stability

Inorganic materials usually have high melting points and thermal stability, which allows them to maintain good structural stability in high temperature environments. Lithium batteries may suffer from thermal runaway in overcharge, short circuit or high temperature environment, and inorganic diaphragm can effectively curb this risk. For example, inorganic materials such as alumina and zirconia do not soften or decompose at high temperatures, thus improving the safety of batteries.

Application prospect of inorganic materials

Solid-state battery

Solid-state batteries are a major trend in future battery technology, and inorganic materials have been widely studied as solid electrolytes. For example, the use of inorganic materials (such as oxides, nitrates, etc.) as solid-state separators can significantly improve the energy density and safety of batteries. At the same time, the solid state battery helps to reduce the internal resistance and prolong the service life of the battery.

High temperature and high power applications

The use of inorganic materials in high temperature constraints is a major advantage, suitable for high temperature environments or fast charging and discharging application scenarios, such as electric vehicles and aerospace.

Development of composite materials

Combining inorganic materials with polymers to form composite materials is an effective way to improve the performance of the diaphragm. By adjusting the type and proportion of inorganic components, the mechanical properties, electrical conductivity and thermal stability of the separator can be optimized, and a safe and efficient lithium battery separator can be designed.

With the increasing demand for high energy density and safety batteries, the application of inorganic materials in lithium battery separators is promising. Here are a few potential applications of inorganic materials in the field of lithium battery separators:

conclusion

Inorganic materials provide a strong choice for the separator materials of lithium batteries due to their superior thermal stability, chemical stability and mechanical strength. With the increasing demand for safe and high-performance lithium batteries, the application prospect of inorganic materials in lithium battery separators is broad, which will promote the further development and innovation of battery technology. In the future, with the progress of material science and the continuous emergence of new technologies, lithium battery separators based on inorganic materials will play a greater role in the field of energy storage, helping to achieve more efficient and safer energy utilization.

Home energy storage product series

A lithium battery pack for home energy storage systems, which is compatible with solar panels and the sun The inverter can work together with the power grid to power household appliances, and it can also be used as a For off grid systems.

Extended reading

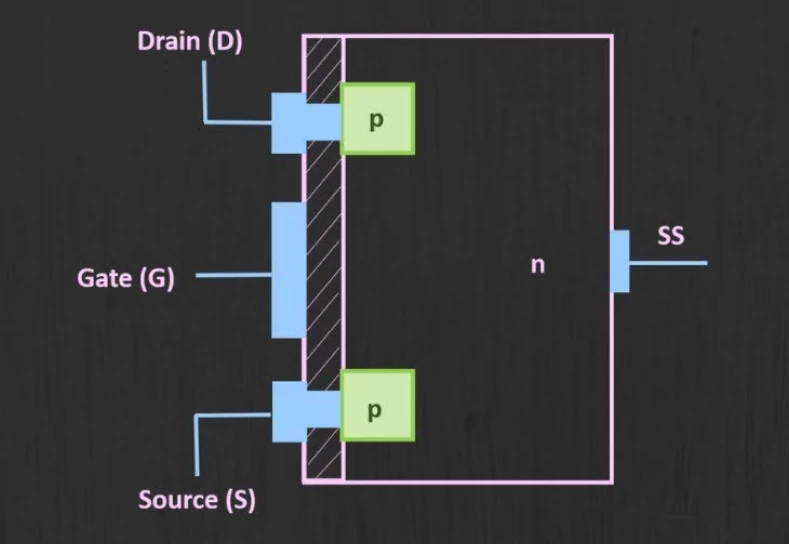

Introduction to enhanced MOSFET

Introduction to enhanced MOSFET what is an enhanced MOSFET Enhancement...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.