A highly integrated backup power solution for solar home energy...

Introduction to thermoplastic elastomers (TPE) for gun head protective covers

The thermoplastic elastomer (TPE) of the gun head protective cover is a new type of polymer material with both rubber elasticity and plastic processing properties. The following is an introduction to the concept, role and working principle of TPE in the application of gun head protection cover:

Main component

concept

A thermoplastic elastomer (TPE) is a polymer that exhibits the properties of thermoset rubber within its design limits, but at temperatures above melt or softening, it is suitable for melts processed by thermoplastic process methods and can be easily reworked and reformed. TPE consists of crystalline and amorphous regions that contribute to the physical and mechanical properties of the material, respectively.

Function

In the application of gun head protection covers, the main roles of TPE include:

Protection: The protective cover made of TPE protects the nozzle from contact with the steel plate during the cutting process, reducing the risk of the nozzle being burned out, thereby extending the service life of the cutting gun.

Cooling: The vent hole on the TPE protective cover can play a guiding role in the cooling gas in the welding gun, which can not only cool the cooling gas to the welding gun, but also avoid the influence of the cooling gas caused by the outflow of the nozzle on the plasma arc and avoid affecting the welding and cutting results.

Environmental protection, non-toxic, safe: TPE material is environmentally friendly and non-toxic, safe and harmless to the human body, and has excellent coloring and weather resistance, which can maintain stable performance in various environments.

Soft to the touch: TPE material can provide suitable hardness, balance wearing comfort and material strength, when in contact with the face, TPE material can provide a soft and comfortable touch.

Working principle

The elastic principle of TPE material is mainly based on its physical cross-linked structure. TPE is composed of a block structure of hard and soft segments, where the hard segment (such as PS as a plastic hard segment) acts as the physical crosslinking point, and the soft segment (such as EB chain segment as a rubber soft segment) provides the flexibility of the material. This physical cross-linked structure enables the TPE material to deform when subjected to external forces and quickly return to its original shape when the external forces are removed. In the headguard, this property allows the guard to maintain its shape when a high-temperature plasma arc passes through, while reverting to its original state when cooled, providing continuous protection and cooling.

In summary, the application of TPE in the gun head protective cover takes full advantage of its unique physical and chemical properties, providing protection, cooling and a comfortable use experience, while ensuring the environmental protection and safety of the material.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Dc charging pile display chip timing controller

Dc charging pile display chip timing controller Main component Concept:...

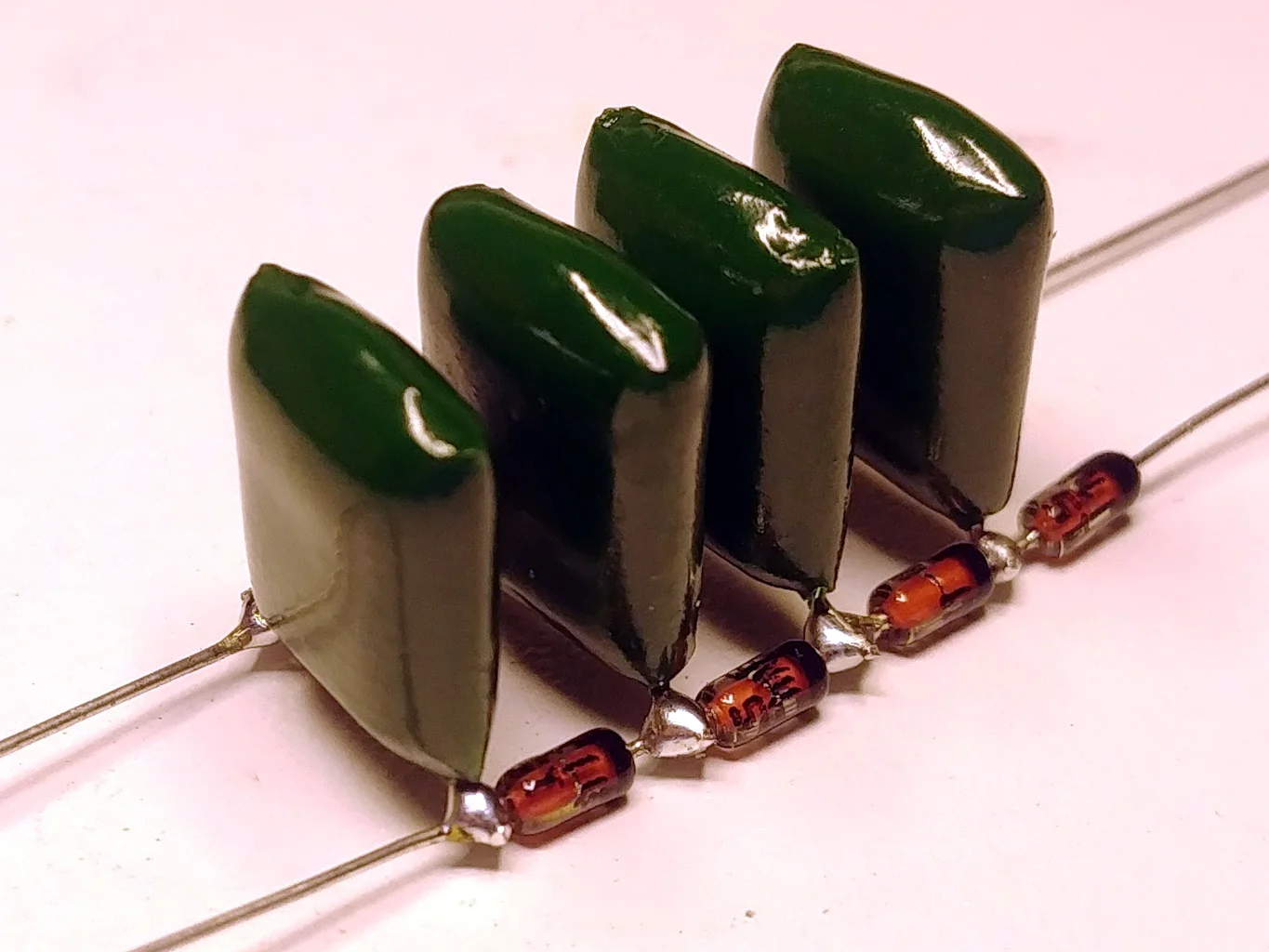

Introduction of diodes in DC charging pile filter

Introduction of diodes in DC charging pile filter Diodes in...

The current limiting protection of DC charging pile power switch chip is introduced

The current limiting protection of DC charging pile power switch...

Components of the control module

Components of the control module Dc charging pile control module...

Charge control chip for trickle/constant current/constant voltage charge control

Charge control chip for trickle/constant current/constant voltage charge control The...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.