Substrate control technology of charge control chip Substrate control of...

An introduction to Housing Material in the indicator light

Main component

In the design and manufacture of the lamp, the choice of building materials is very important. These materials not only affect the appearance and durability of the indicator, but also directly relate to its functionality and safety. Common building materials mainly include plastic, metal and glass.

Plastic is one of the most commonly used building materials for indicators, and is widely used because of its lightweight, corrosion resistance and low cost. Common types of plastics include polycarbonate and polypropylene, which have excellent impact and UV resistance and are suitable for outdoor environments. At the same time, plastic also offers the possibility of a variety of colors and shapes, which facilitates designers to carry out diversified product development.

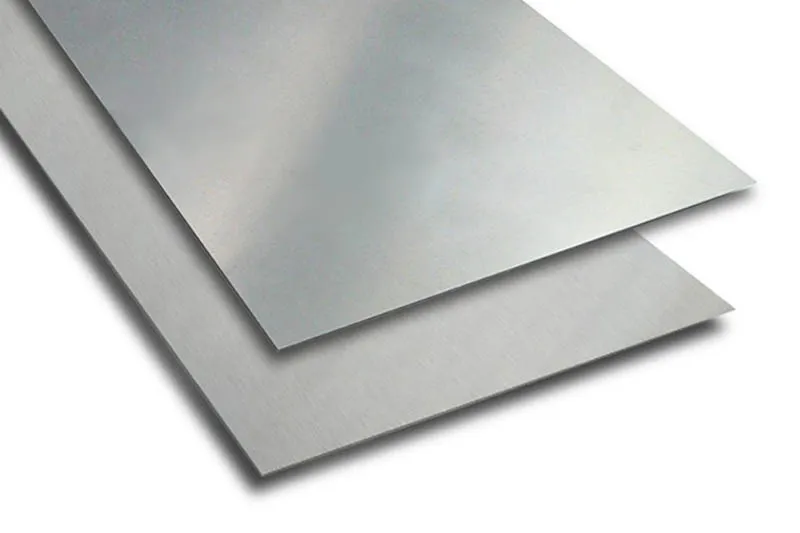

Metallic materials such as aluminum and stainless steel are commonly used for high-end or industrial use indicators. Metal not only provides stronger structural strength and durability, but also has better heat dissipation performance, which is suitable for high-power LED indicators. Aluminum is light and easy to process, while stainless steel has won a wide range of applications for its excellent corrosion resistance and elegant appearance.

Glass is often used in high-end indicators and decorative lamps, and its transparency and beauty make the light more gentle and evenly distributed. Special glass materials that are resistant to high temperature and breakage guarantee the safety and durability of the indicator light in a variety of environments.

Overall, the choice of building materials directly affects the performance, life and beauty of the indicator light, designers need to consider the characteristics of different materials when selecting materials to meet the needs of different application scenarios.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Introduction to the application of stainless steel plate in DC charging pile

Introduction to the application of stainless steel plate in DC...

Introduction of light emitting diode of DC charging pile indicator light

Introduction of light emitting diode of DC charging pile indicator...

Visual indicator of mechanical locking device

Visual indicator of mechanical locking device Visual indicators are an...

Dc charging pile display chip timing controller

Dc charging pile display chip timing controller Main component Concept:...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.