What is the function of the insulator of the communication...

About the heat dissipation materials in the indicator

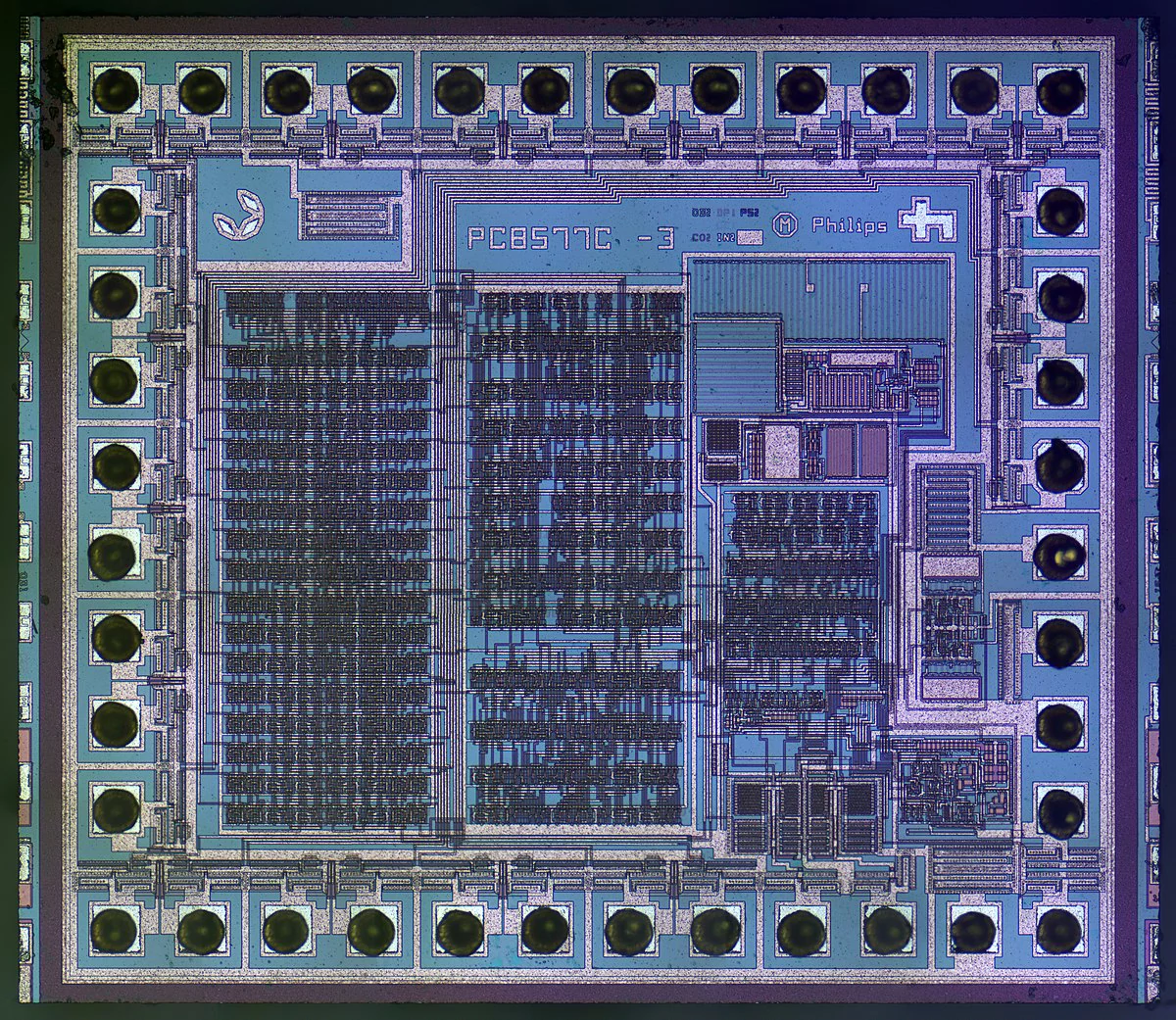

Main component

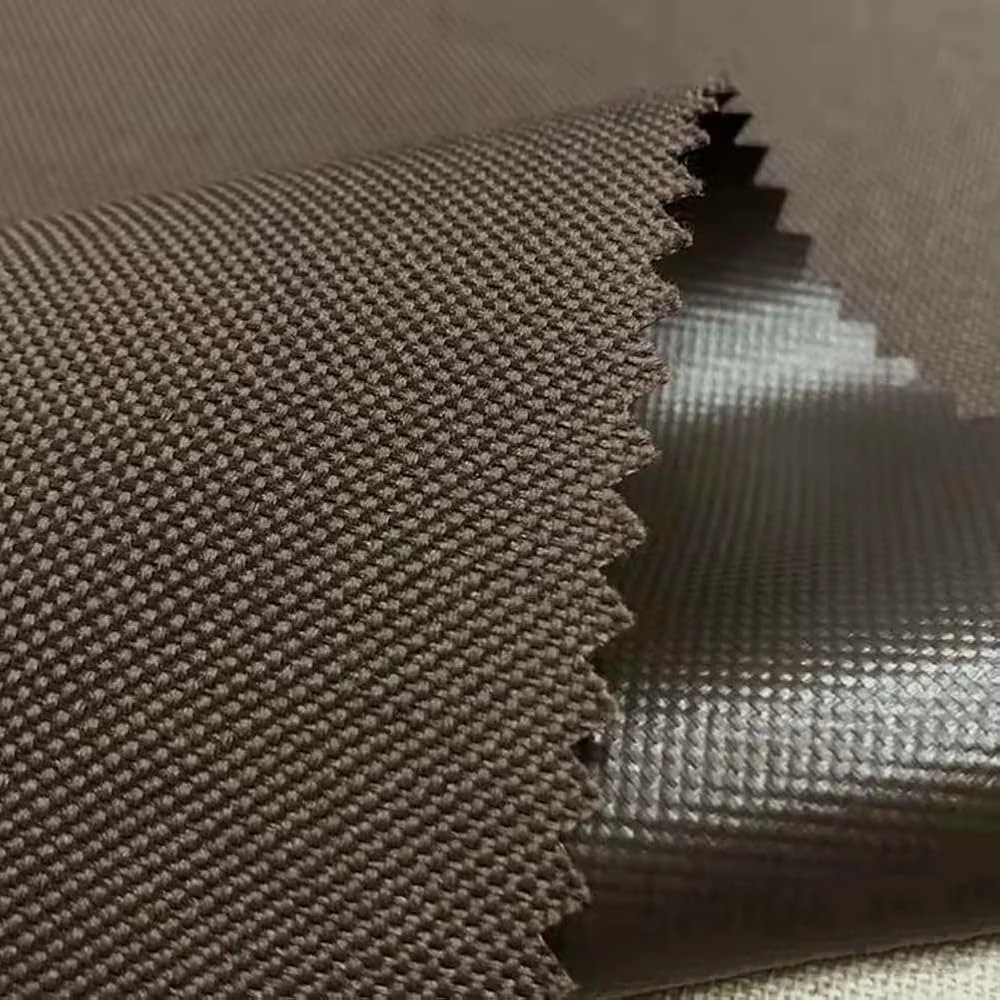

In the design and application of the indicator light, the use of cooling materials is very important. Light-emitting diodes (leds), although excellent in terms of energy efficiency, still generate a certain amount of heat during their operation. Effective cooling materials can help control the temperature of the LED to ensure that it is operating in optimal condition, thereby extending its service life and improving light efficiency.

Common heat dissipation materials include aluminum alloy, copper and thermal conductive plastics. Because of their good thermal conductivity, these materials are widely used in the heat dissipation system of LED indicators. Because of its light weight and excellent thermal conductivity, aluminum alloy is often used in the design of heat sinks, which can quickly and efficiently conduct the generated heat to the surrounding environment. Copper has higher thermal conductivity and is suitable for high-power LED applications that require greater heat dissipation.

In addition to traditional metal heat dissipation materials, modern technology has also developed many composite materials and thermal interface materials, which combine excellent thermal conductivity and insulation properties, and can prevent electrical short circuits while maintaining the heat dissipation effect. The design of the heat dissipation material not only considers the thermal conductivity, but also takes into account the heat dissipation area and air circulation, providing an ideal working environment for the LED.

In short, in the application of the indicator, the choice and design of the cooling material is a key factor to ensure the stability and performance of the LED, which helps to improve the reliability and service life of the device.

DC CHARGING PIlE SERIES

DC charging pile is an efficient charging facility for electric vehicles, which uses direct current (DC) to directly charge the vehicle battery, significantly reducing the charging time. Compared with traditional AC charging piles, DC charging piles are able to provide higher power output and can usually charge an EV to 80% of its capacity in 30 minutes, providing users with a convenient charging experience.

Extended reading

Protective Cover of DC charging pile

Protective Cover of DC charging pile Main component Concept: Protective...

What does a mechanical locking mechanism consist of

What does a mechanical locking mechanism consist of The mechanical...

Introduction of integrated components in the electronic locking mechanism of the gun muzzle of DC charging pile

Introduction of integrated components in the electronic locking mechanism of...

The introduction of insulating materials for DC charging pile transformer

The introduction of insulating materials for DC charging pile transformer...

DC charging pile DC Positive Pole Contact (DC+ Contact)

DC charging pile DC Positive Pole Contact (DC+ Contact) Main...

THE ESSC Brand promise

Global supply

Our products sell well all over the world, covering many countries and regions, through the global logistics network, to provide customers with convenient purchasing experience.

Rigorous quality

We adhere to the highest quality control standards to ensure every product meets industry regulations and customer expectations, earning trust through consistent excellence.

Excellent service

With a customer-centric approach, we provide prompt responses, professional support, and personalized services, aiming to deliver the best user experience and long-term value.